Automatic wall trowelling machine with function of automatic adjustment of scraper angle

A technology of automatic adjustment and leveling machine, applied in the direction of construction, building structure, etc., can solve the problems of low work efficiency, time-consuming and laborious, and large workload of manual leveling of walls, etc., to achieve convenient operation, reduce labor intensity, shorten the time The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

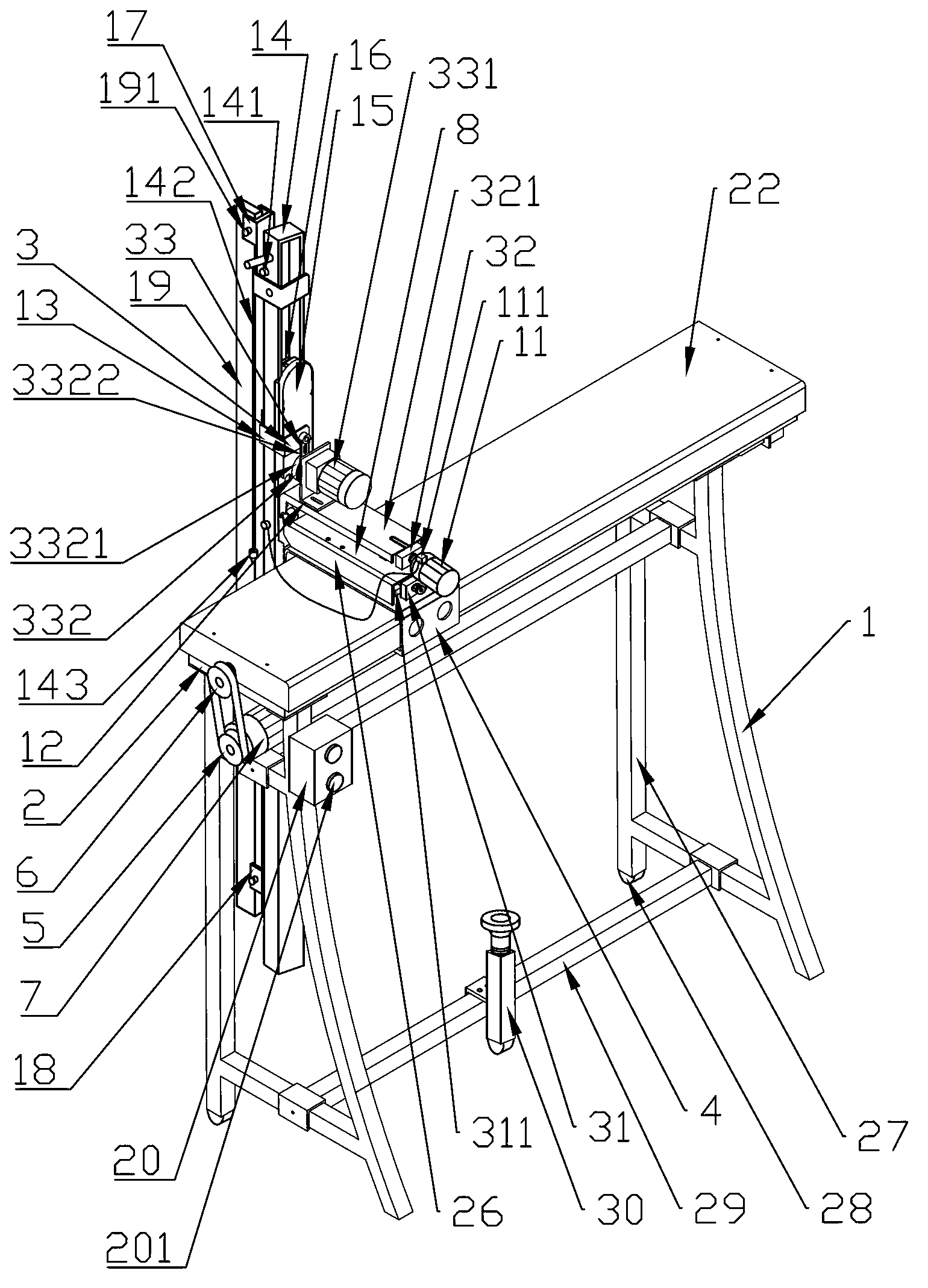

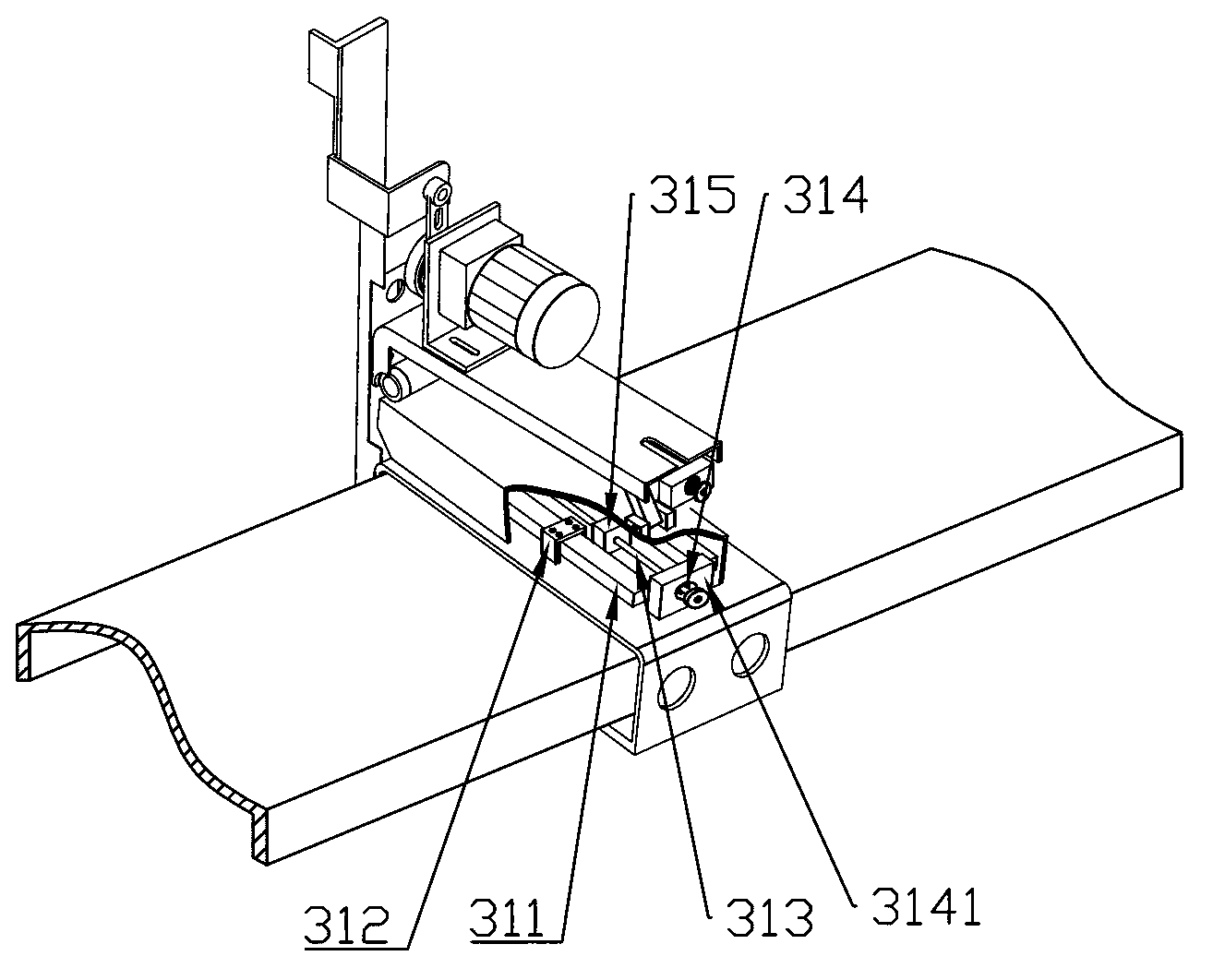

[0020] Such as Figure 1-5 As shown, the present invention is an automatic wall smoothing machine with the function of automatically adjusting the angle of the scraper, including an arc-shaped support 1 , an automatic lateral movement adjustment device 2 and an automatic wall smoothing device 3 .

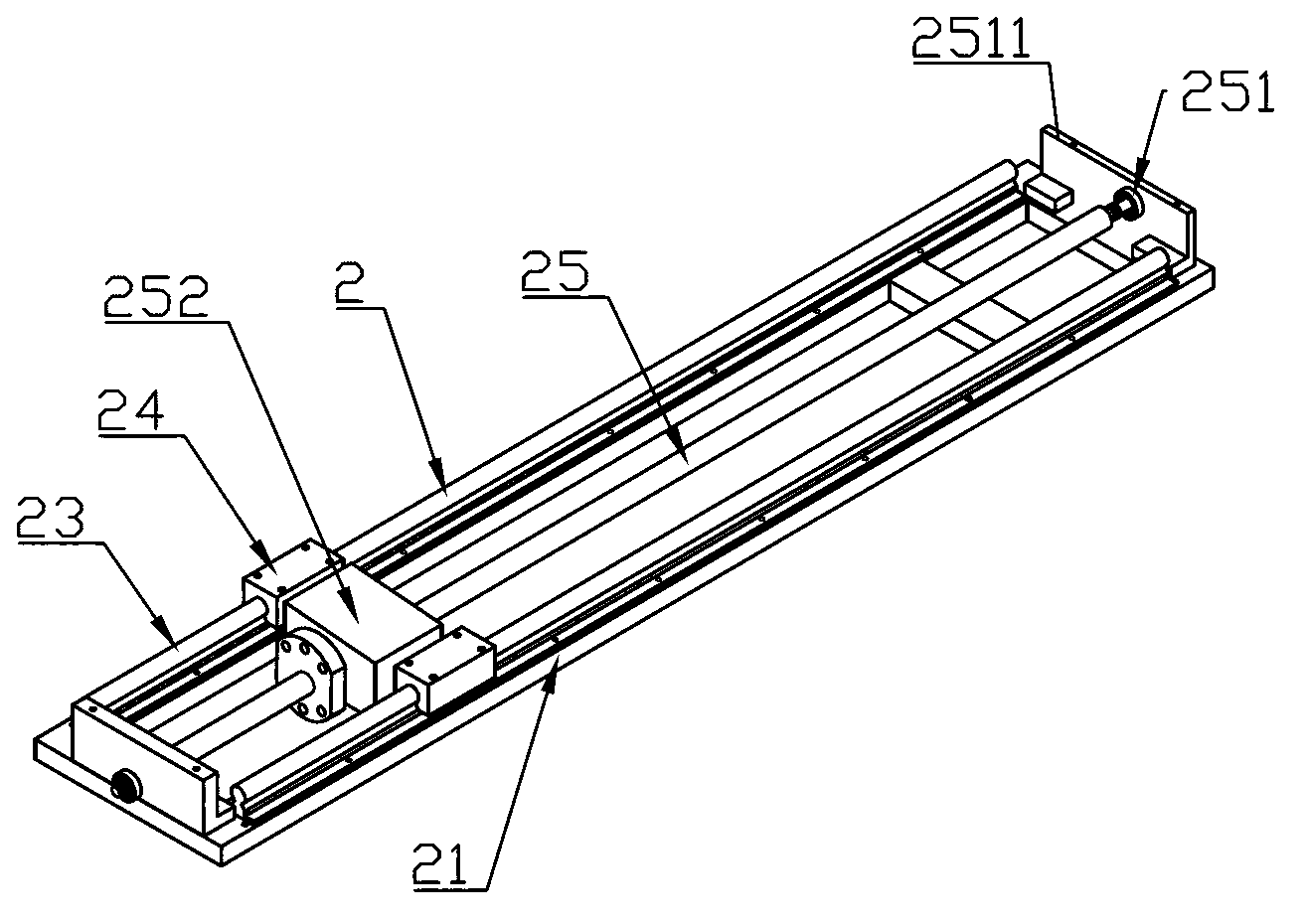

[0021] The automatic lateral movement adjustment device 2 includes a rectangular bottom frame 21 provided at the bottom, and the automatic lateral movement adjustment device 2 is fixed on the above-mentioned arc-shaped support 1 through the rectangular bottom frame 21 provided at the bottom, and the automatic lateral movement adjustment device 2 2 also includes a dust cover 22, the dust cover 22 covers the upper part of the lateral movement automatic adjustment device 2;

[0022] The front and rear sides of the rectangular bottom frame 21 are respectively provided with a linear slide rail 23, and the two linear slide rails 23 are respectively provided with a first slider 24 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com