Method for manufacturing diesel engine control box with support

A manufacturing method and diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of blind search, easy collision, damage to modules in the box, etc., to reduce wiring error rate, stable and reliable use, and improve Effect of Wiring Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

[0022] The present invention uses a plurality of diesel engine control boxes and movable masts.

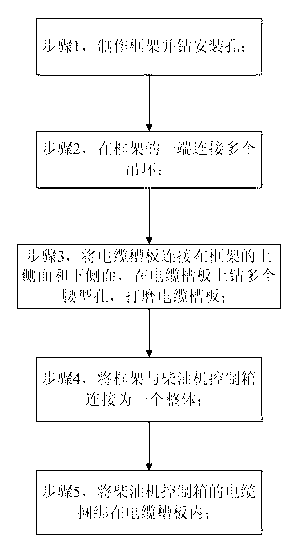

[0023] like figure 1 Shown, a kind of diesel engine control box manufacturing method with support of the present invention comprises the following steps:

[0024] In step 1, the metal strips are connected to form a frame 1, and a plurality of installation holes 13 are drilled on the frame 1.

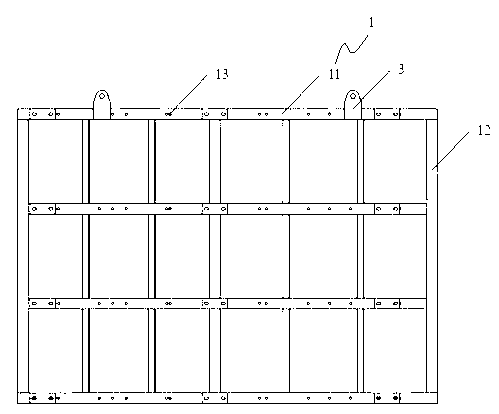

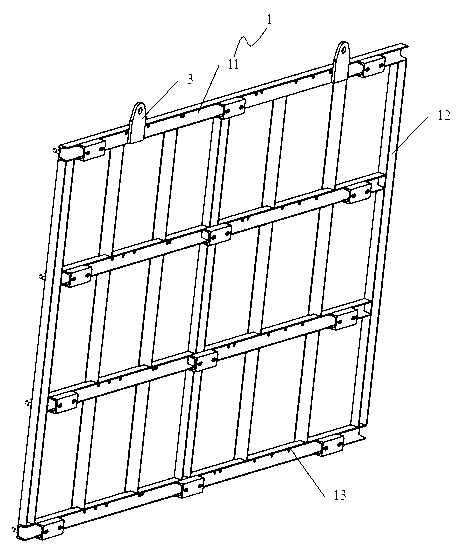

[0025] like figure 2 and image 3 As shown, frame 1 is rectangular. The frame 1 includes a plurality of horizontal metal strips 11 arranged parallel to each other and a plurality of vertical metal strips 12 arranged parallel to each other at intervals, and each horizontal metal strip 11 is vertically connected to each vertical metal strip 12 respectively. The material of the horizontal metal strip 11 and the vertical meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com