Anti-off rotation mechanism

A rotating mechanism and anti-dropping technology, applied in harvesters, connecting components, mechanical equipment, etc., can solve the problems of inconvenient installation, easy loosening of the rotating structure, and high mold requirements, and achieve convenient installation, reliable connection, and novel mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

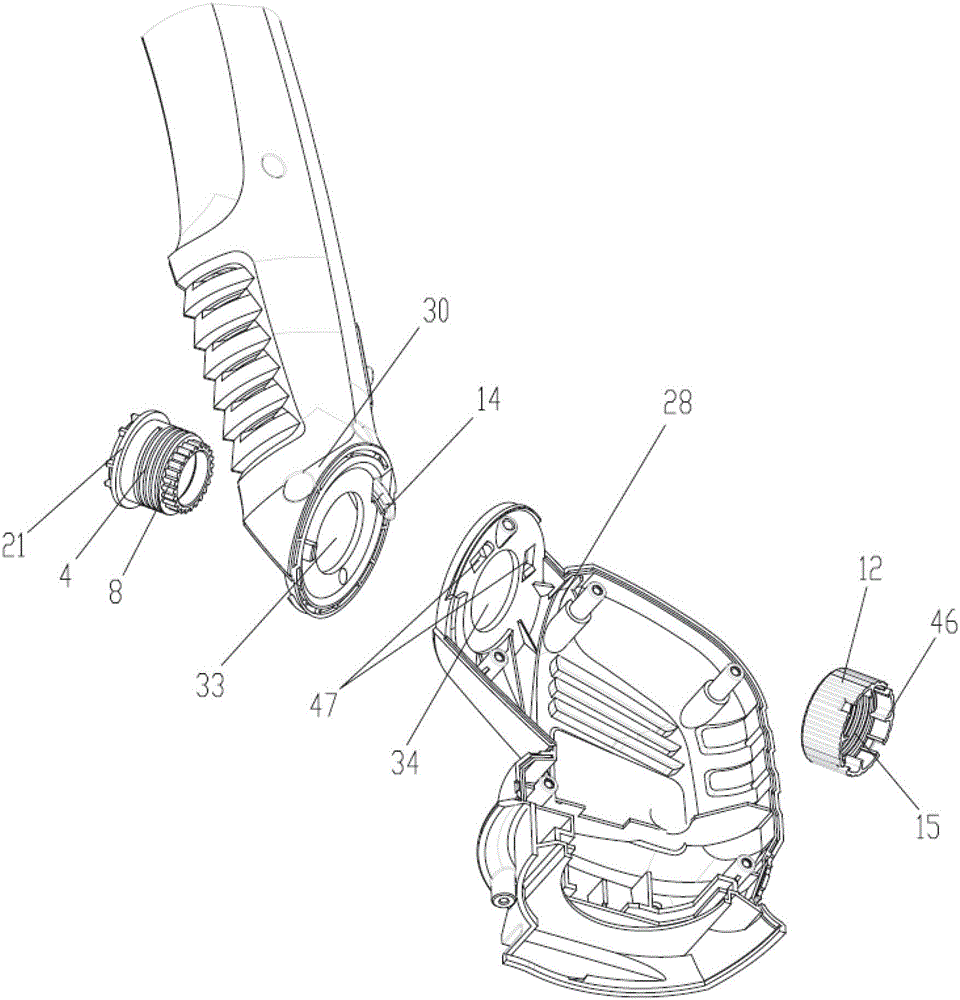

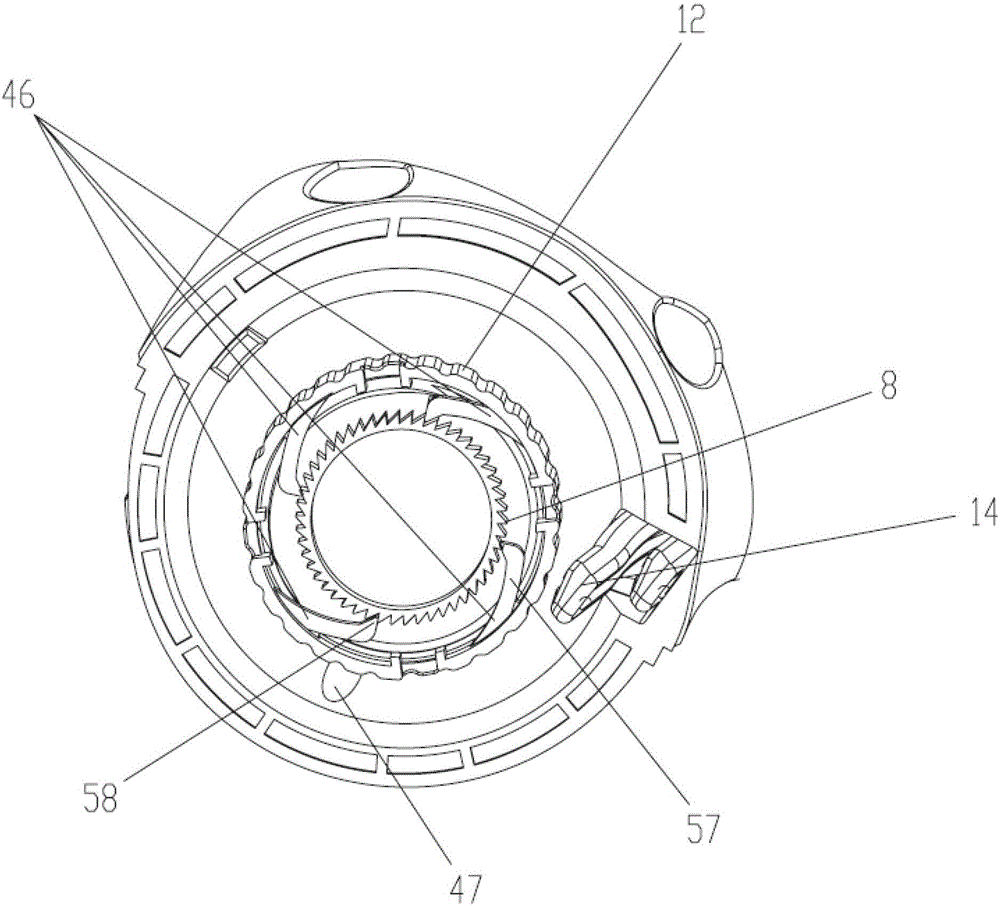

[0018] refer to figure 1 , the anti-off rotation mechanism corresponding to the preferred embodiment of the present invention can be applied to a lawnmower among gardening tools, and the lawnmower includes a handle part 30 and a machine head 28 matched with the handle part 30 . Wherein, the handle portion 30 is provided with a first through hole 33 and a positioning portion 14 positioned beside the first through hole 33 , while the handpiece 28 is provided with a second through hole 34 and at least one position positioned beside the second through hole 34 . Positioning groove 47. The optimal number of the positioning grooves 47 is two. When the handpiece 28 needs to rotate to a specific position relative to the handle 30 , the positioning portion 14 can be selectively snapped into the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com