Cold isostatic press superhigh pressure sealing device and manufacturing process of sealing ring of cold isostatic press superhigh pressure sealing device

A cold isostatic press and sealing device technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of short service life, high price, difficult sealing, etc., to improve the guiding performance, reduce the friction coefficient, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

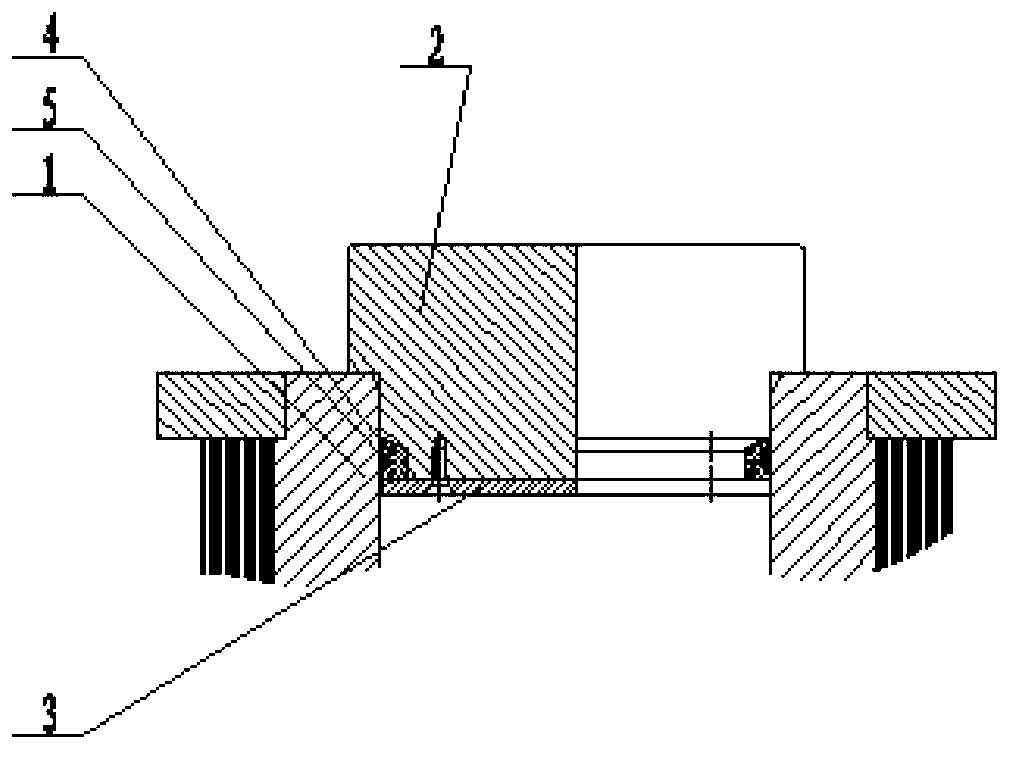

[0025] This example figure 1 shown.

[0026] An ultra-high pressure sealing device for a cold isostatic press, which includes a sleeve 1, which is accommodated in the sleeve 1 and abutted against a cover 2, and the lower end of the cover 2 is fixed with a lower pressure plate 3 by bolts, An installation groove is provided between the lower part of the cover 2 and the lower pressure plate 3, a sealing ring 4 is arranged in the installation groove, an O-ring 5 is arranged in the sealing ring 4, and the sealing ring 4 is made of nylon , Molybdenum disulfide, bronze powder and graphite.

[0027] Preferably, in order to make the seal ring have the best wear resistance and rebound performance, improve its guiding and prolong the service life, the mass percentage of nylon, molybden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com