Spring fatigue testing machine

A technology of fatigue testing and spring sleeve, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., to achieve the effect of convenient use, reasonable design and accurate test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

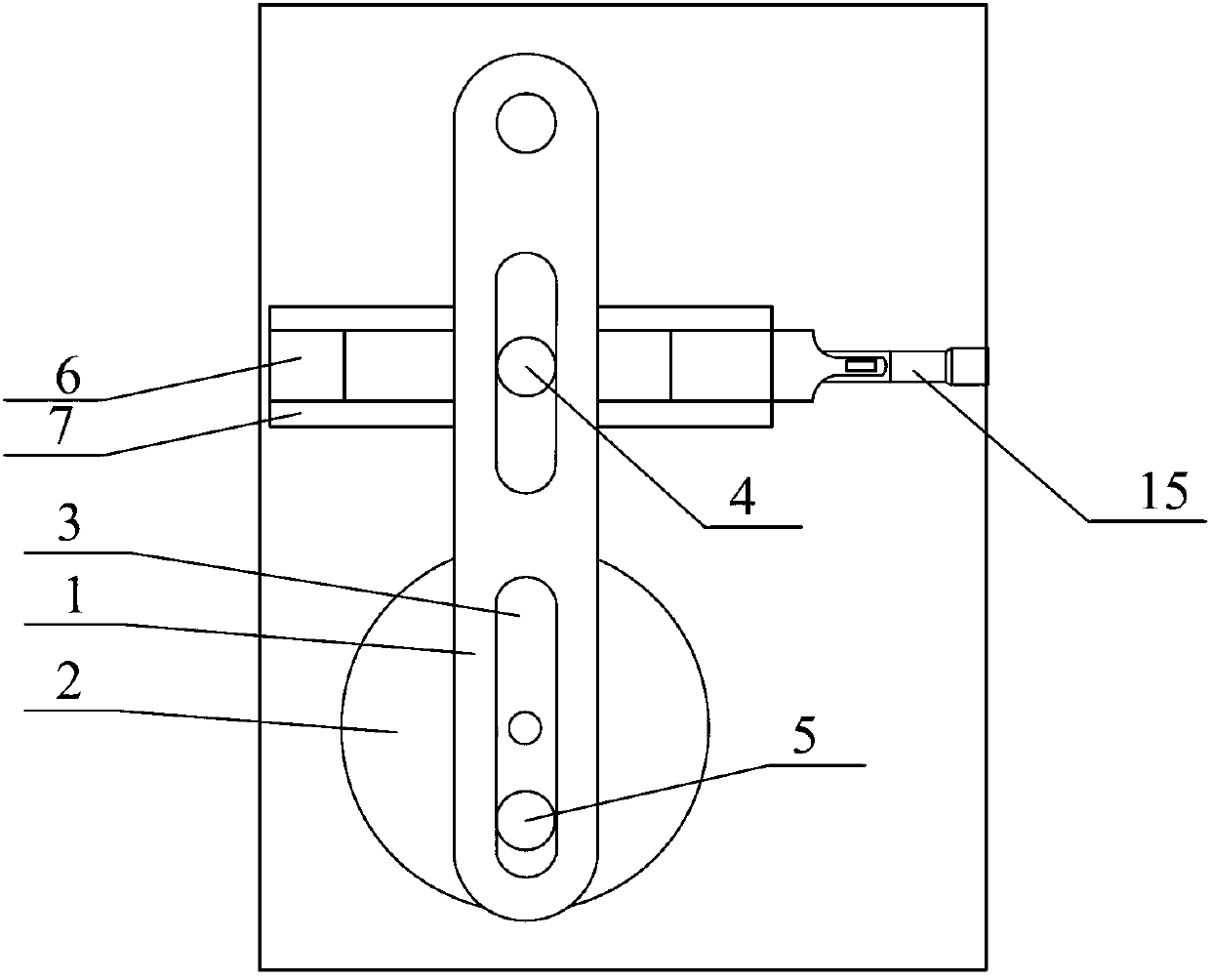

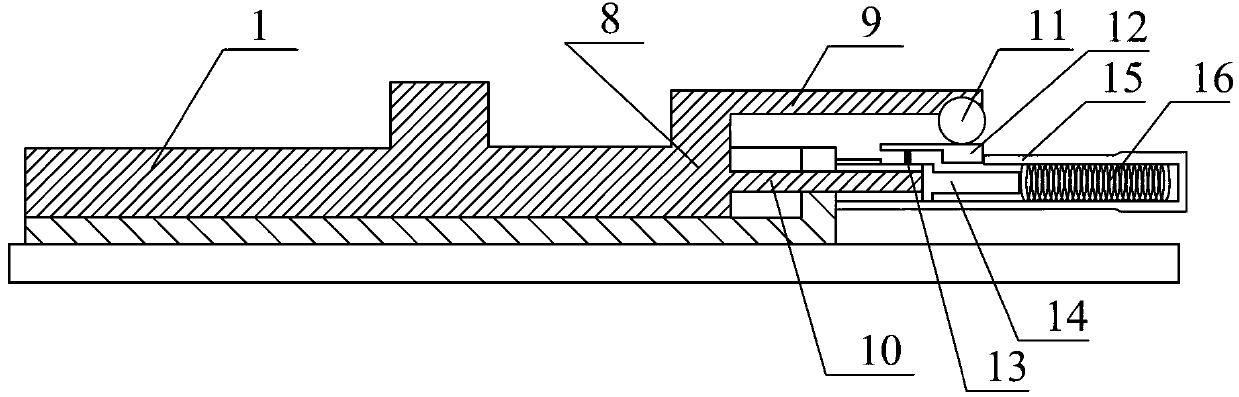

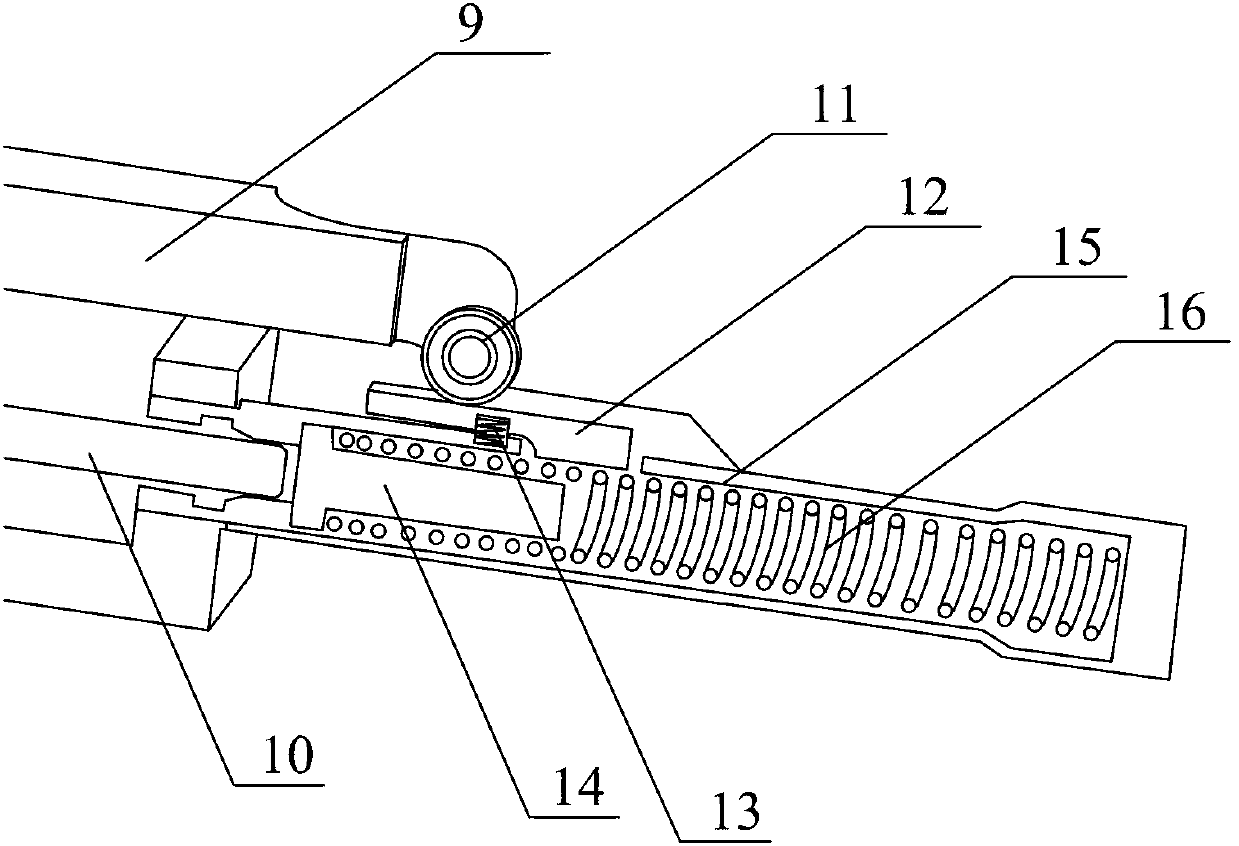

[0017] Such as figure 1 The swing connecting rod in the shown spring fatigue testing machine includes a swing rod 1 and a cam 2. The two ends of the swing rod 1 are provided with a long slot 3, and the cam protrusion 5 on the cam 2 is inserted into the side of the swing rod 1. Through slot 3, the slide rail protrusion 4 is inserted into the through slot 3 on the other side of the swing rod 1, and the cam protrusion 5 and the slide rail protrusion 4 match the width of the through slot 3 of the swing rod 1 to prevent errors in the power transmission process and make the cam 2 The rotation can be accurately transmitted to the slide rail 6. Slide rail 6 slides in chute 7. The end of the slide rail 6 is an F-shaped end 8, the tail of the upper horizontal side 9 of the F-shaped end 8 is provided with a compression bearing 11, the lower horizontal side 10 of the F-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com