Clamp for replacing glass insulator for power transmission line

A technology for glass insulators and transmission lines, which is applied to overhead lines/cable equipment, etc., can solve the problems of wasting manpower, low work efficiency, and difficult to cooperate, and achieves the effect of reducing labor intensity, improving work efficiency, and being easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

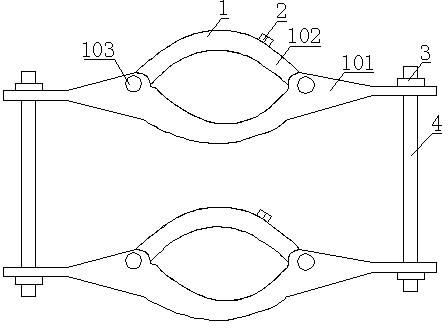

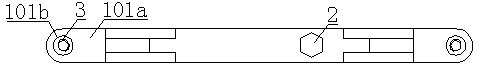

[0020] As shown in the figure, the power transmission line replacement glass insulator card has two hooks 1 . In this embodiment, the hook 1 is composed of a main hook body 101, a hook lock block 102 and a screw 103. Both ends of the hook lock block 102 are respectively connected to the main hook body 101 by screws 103. The main hook body 101. The hook lock block 102 forms a hollow spindle shape. One side of the hook 1 is provided with fastening bolts 2, and the two ends of the main hook body 101 of the hook 1 are respectively provided with connecting plates 101a, and each connecting plate 101a is provided with a connecting hole 101b, and the connecting holes 101b The plane where it is located is perpendicular to the large end face of the hook 1 . Threaded sleeves 3 are provided in the connecting holes 101b, and lead screws 4 are respectively provided between two corresponding threaded sleeves 3 . The threads of the two corresponding threaded sleeves 3 have opposite directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com