Hydrophobic sand preparation method adopting waste polystyrene foam as raw material

A technology for discarding polystyrene and polystyrene, applied in the fields of botanical equipment and methods, soilless cultivation, cultivation, etc., can solve the problems of unreasonable utilization, pollution, waste of irrigation water, etc., and achieve saving irrigation water and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

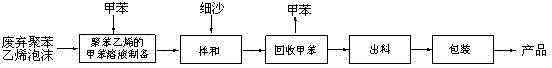

[0010] Add 10 g of waste polystyrene foam to 150 g of toluene to form a polystyrene toluene solution, add 500 g of fine sand, stir evenly, and then discharge, decompress and heat to recover the toluene, discharge after cooling, and pack to obtain the product.

Embodiment 2

[0012] Add 10 g of waste polystyrene foam to 150 g of toluene to form a polystyrene toluene solution, add 600 g of fine sand, stir evenly and discharge, decompress and heat to recover toluene, discharge after cooling, and pack to obtain the product.

Embodiment 3

[0014] Add 10 g of waste polystyrene foam to 150 g of toluene to form a polystyrene toluene solution, add 700 g of fine sand, stir evenly and discharge, reduce pressure and heat to recover toluene, discharge after cooling, and pack to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com