Roller weldment hydraulic positioning and rotating device

A technology of hydraulic positioning and rotating device, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the workload of workers and hidden dangers, heavy drum welding parts positioning device, difficult work efficiency, etc. The effect of promotion, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments.

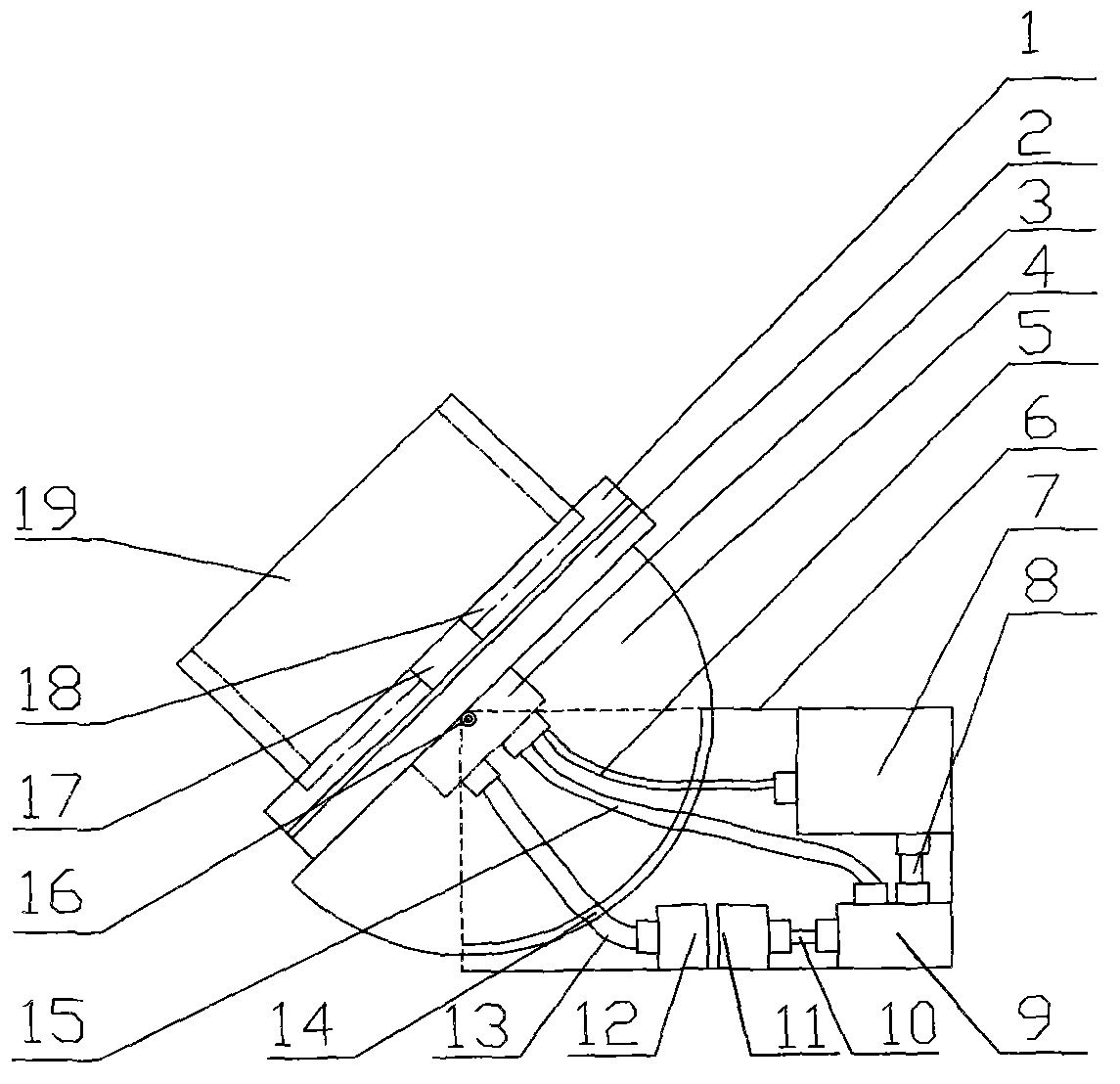

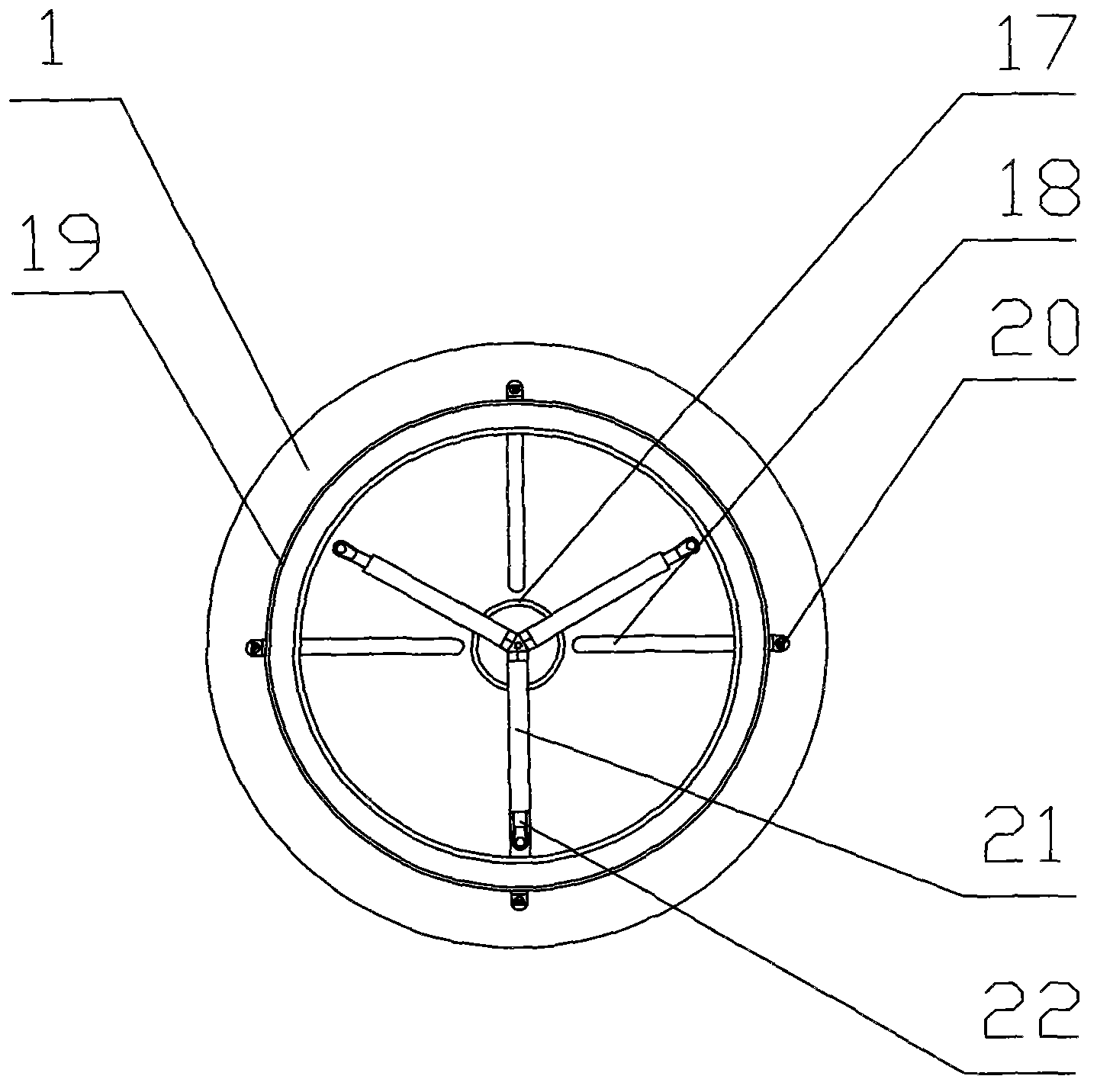

[0014] The invention relates to a hydraulic positioning and rotating device for a drum weldment, comprising a power control device and a hydraulic positioning device. The power control device includes a base 6, a rotation control device 3, a rotation cable 13, a rotation motor 12, a hydraulic motor 11, a hydraulic cable 10, a hydraulic pump 9, a hydraulic oil supply pipe 8, a hydraulic oil tank 7, a hydraulic oil inlet pipe 15, and a hydraulic oil return pipe 5. The rotating motor 12 is placed on the base 6, the rotating control device 3 is connected with the rotating motor 12 through the rotating cable 13, the hydraulic motor 11 is placed on the base 6, the hydraulic pump 9 is connected with the hydraulic motor 11 through the hydraulic cable 10, and the hydraulic The oil tank 7 is connected with the hydraulic pump 9 through the hydraulic oil supply pipe 8, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com