Grinding fluid distribution arm

A technology of grinding fluid and distributing arm, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to achieve flatness, not distributed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so that the realization process of how to use technical means to solve technical problems and achieve technical effects in the present invention can be fully understood and implemented accordingly.

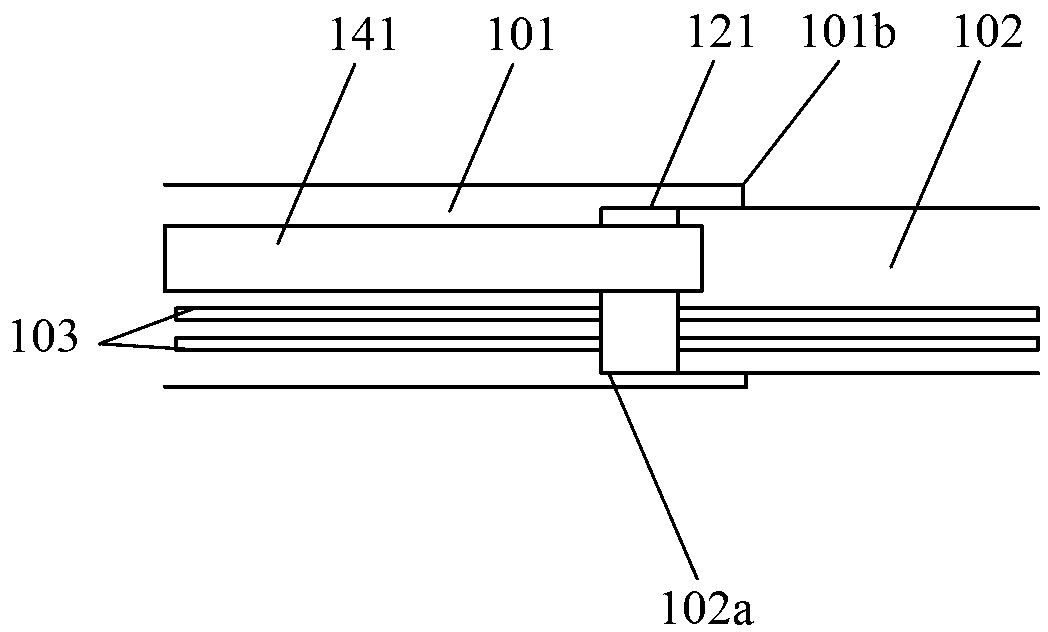

[0023] In the following embodiments of the present invention, by controlling the swing of the first mechanical arm and the swing of the second mechanical arm through the control module, not only the flow control can be realized, but also the relative position between the output port of the grinding liquid and the grinding table can be adjusted, Therefore, the control of the spraying direction of the grinding liquid at the output port of the grinding liquid is realized, and the linear and distributed control are finally realized.

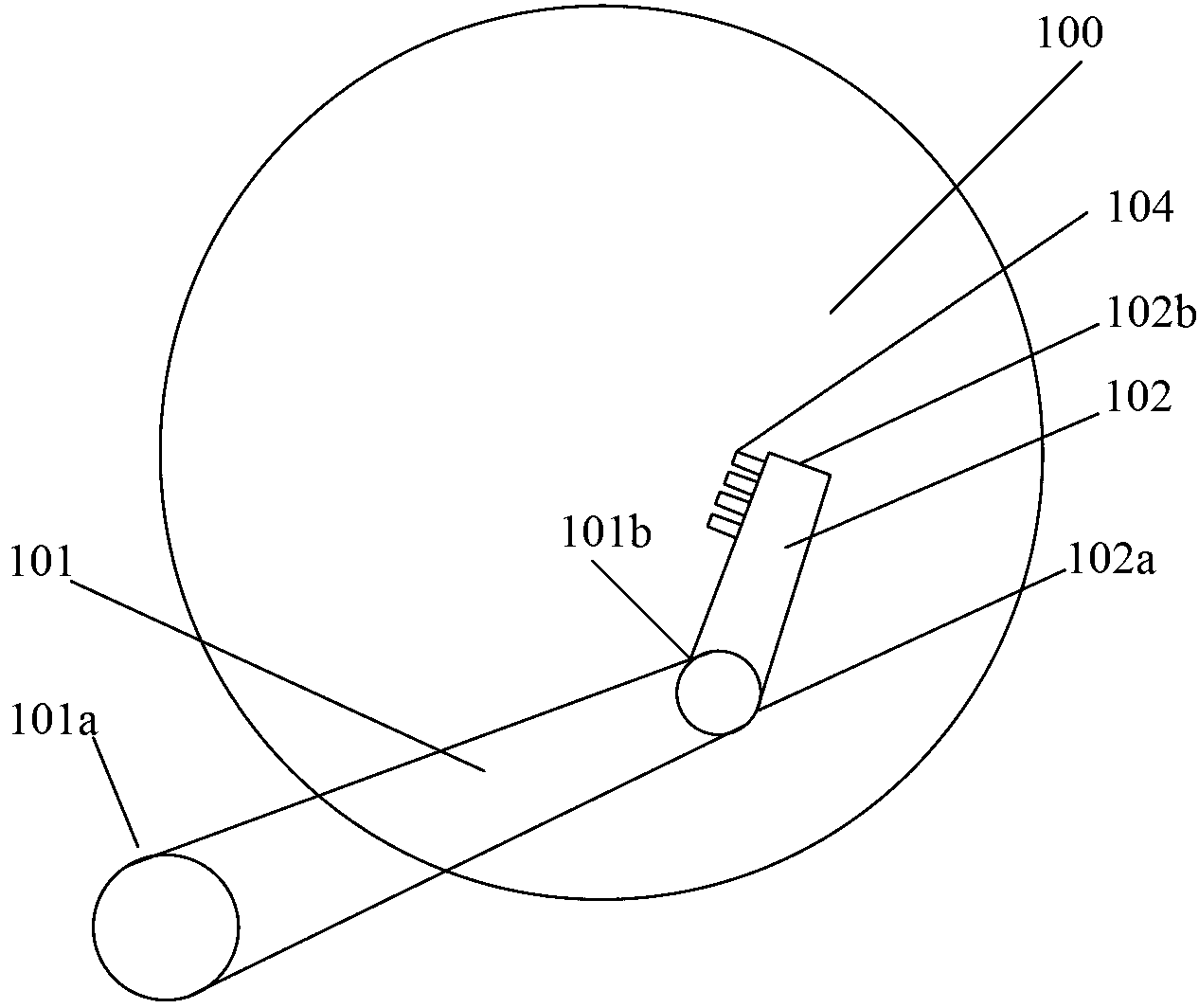

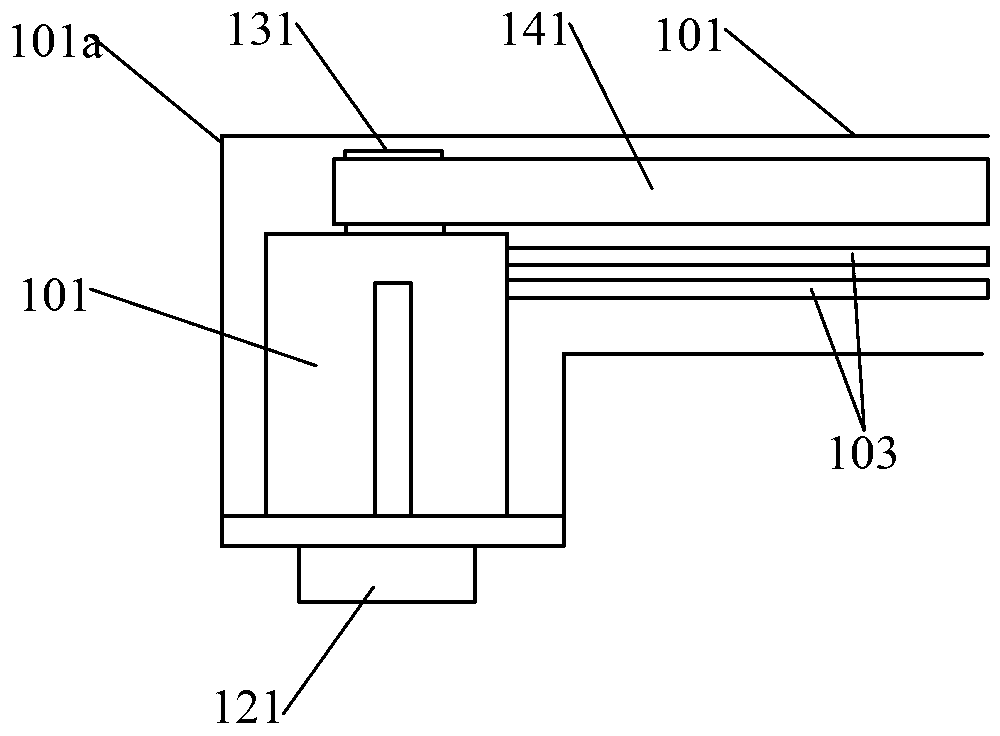

[0024] Such as figure 1 As shown, it is a schematic plan view of the structure of the grinding liquid distribution arm acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com