Pipeline centralizer

A technology of centering devices and pipelines, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as unstable ground foundation, high safety risks, and unstable jack driving points, so as to reduce unsafe behaviors and safety risks , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

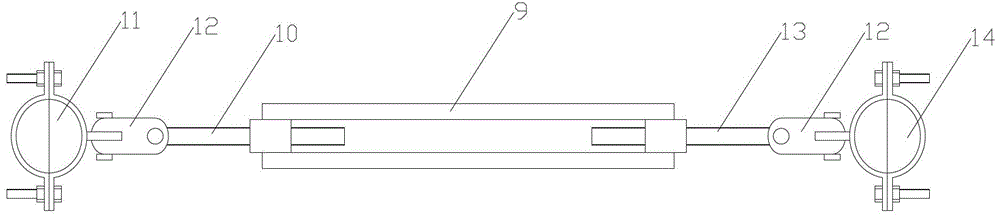

[0018] In order to better understand the purpose, structure and function of the invention, a pipeline centralizer of the present invention will be further described in detail below in conjunction with the accompanying drawings.

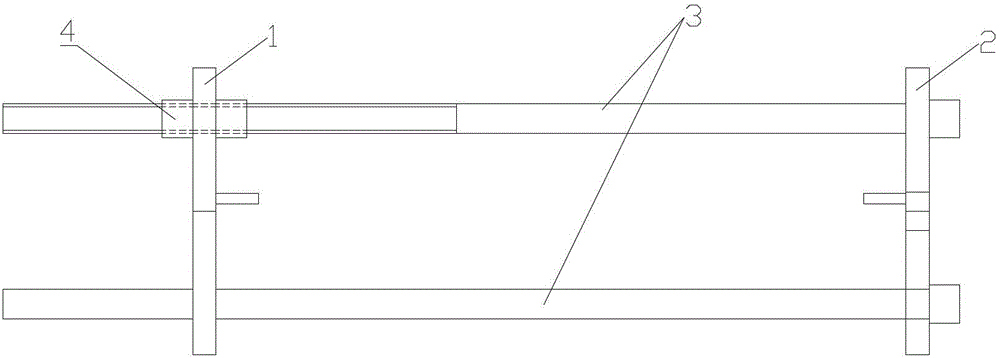

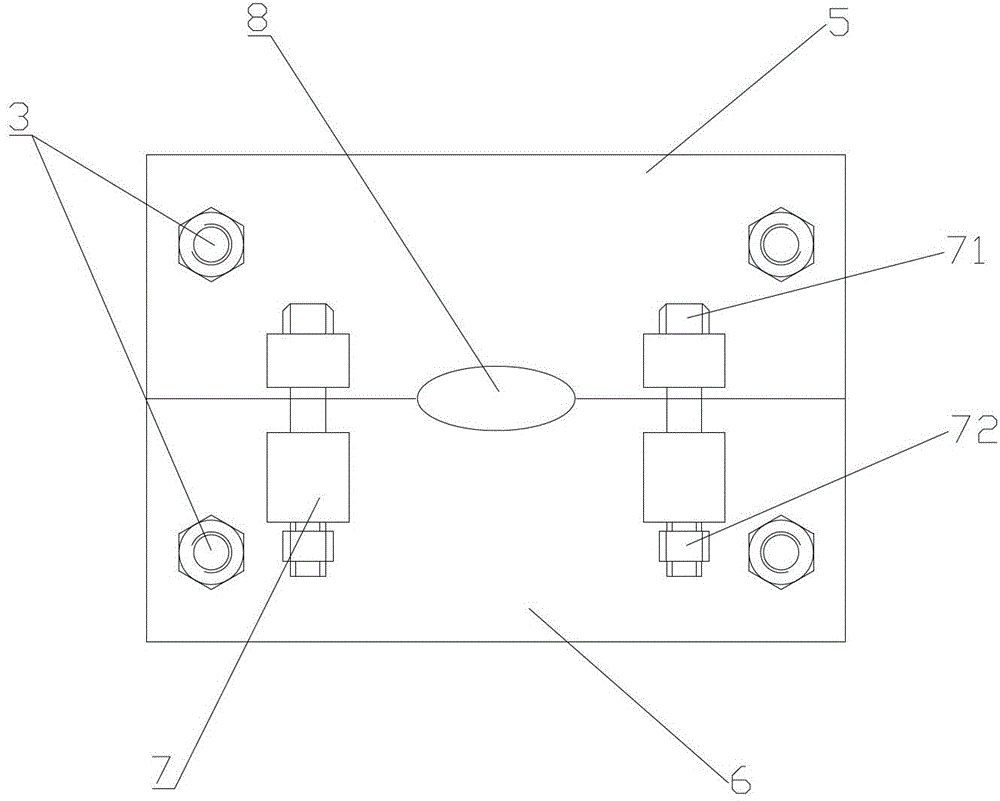

[0019] see figure 1 with figure 2 , which shows the first embodiment of the pipeline centering device of the present invention, the pipeline centering device of this embodiment is mainly used for replacing gates, steel rings, gaskets and other maintenance work requiring alignment on straight pipelines .

[0020] Such as figure 1 As shown, the pipeline centralizer of this embodiment includes a movable splint 1 and a fixed splint 2, the movable splint 1 and the fixed splint 2 are arranged on the guide rod 3, and the fixed splint 2 and the guide rod 3 are fixed on the Together, the movable splint 1 is slidably connected with the guide rod 3 , so that the movable splint 1 can move relative to the fixed splint 2 on the guide rod 3 to change the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com