Drilling lineation method for skin part

A skin part, drilling and marking technology, applied to workshop equipment, manufacturing tools, etc., can solve the problems of difficult marking, large measurement error, low marking accuracy and efficiency, and improve the marking accuracy of holes , Realize mass production and improve the efficiency of scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

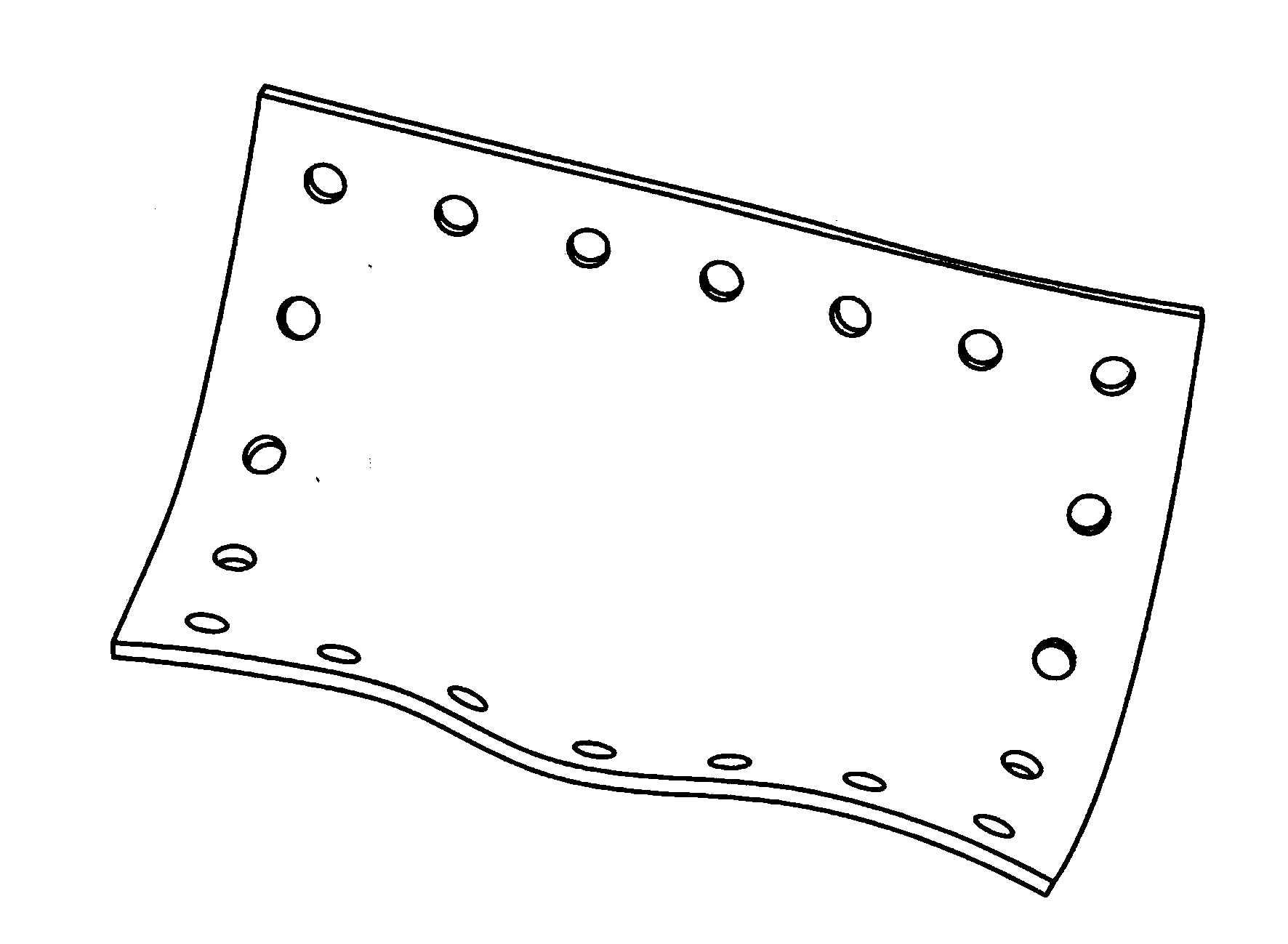

[0018] Such as figure 1 Shown, a method for drilling and scribing skin parts, comprising the following steps:

[0019] 1) Taking the bottom surface of the skin part forming mold as the datum plane of projection, project the outer edge line of the skin part and the center point of each hole along the direction of the datum plane on the datum plane according to the size;

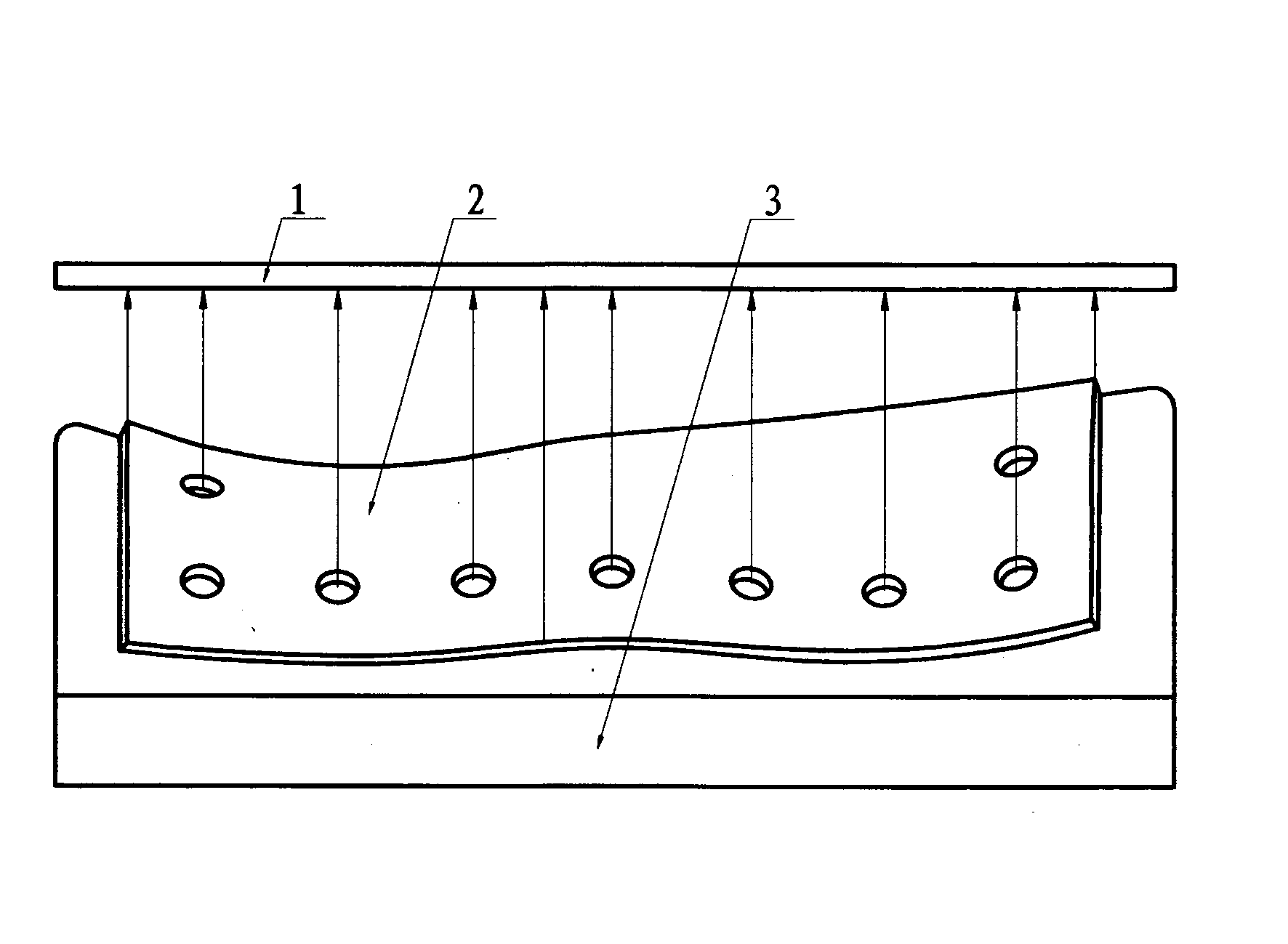

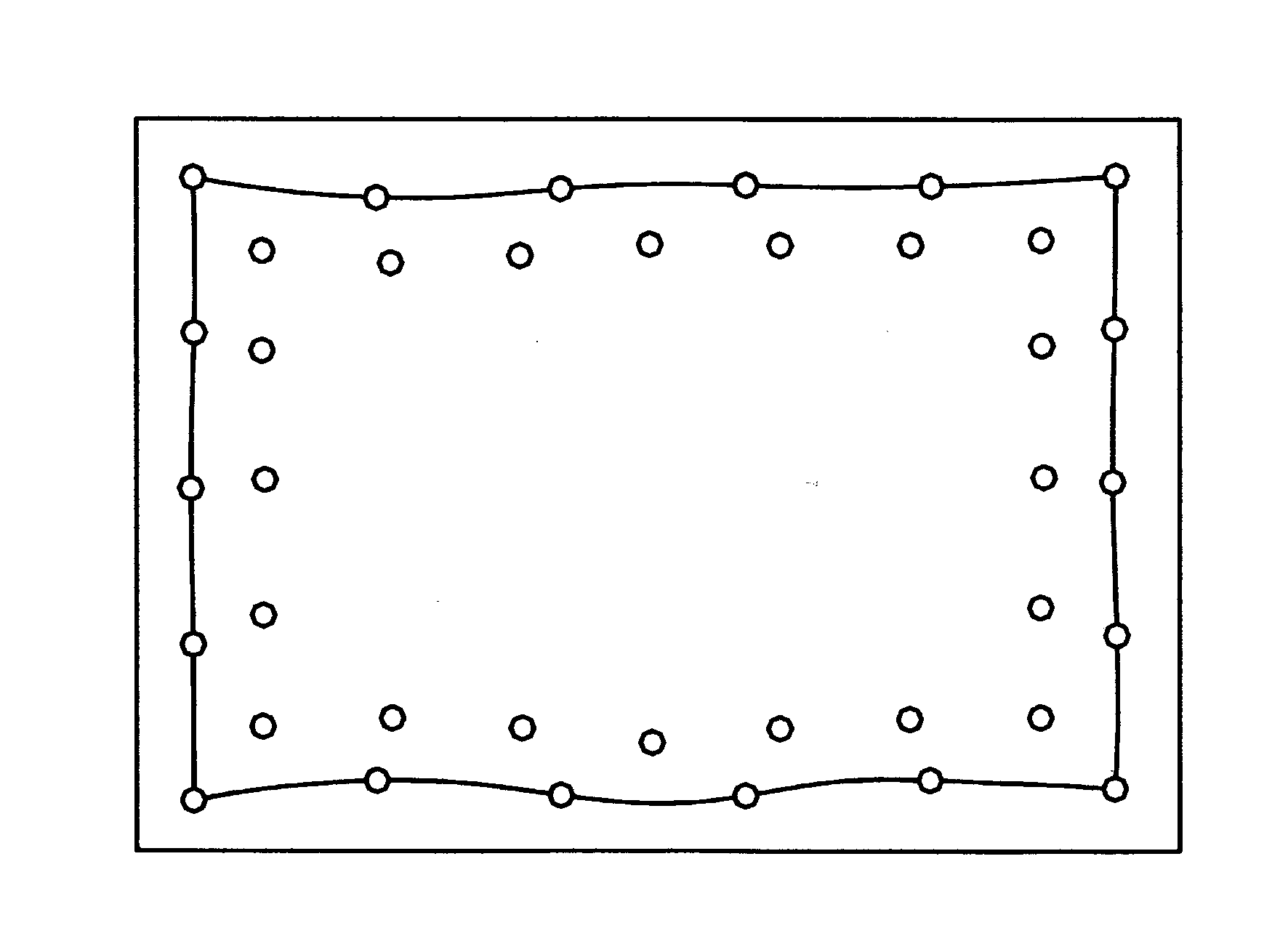

[0020] 2) if figure 2 As shown, the projected outer edge line projected on the datum plane and the projected point of the hole are drawn on a steel plate with a thickness of 3-5mm at a ratio of 1:1;

[0021] 3) if image 3 As shown, light holes with a diameter of Ф1mm are drilled at the projection points of each hole; light holes arranged equidistantly are drilled at the position of the projected outer edge line, and the number is 10-20;

[0022] 4) Place the forming mold of the skin part on a horizontal workbench, position the skin part on the forming mold, and then place the steel plate above the skin pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com