Double-inclined hydraulic type coating trolley system of marine pipeline concrete balance weight

A technology for concrete and pipes, applied in the field of double inclined hydraulic coating trolley system and marine pipeline counterweight production equipment, can solve the problems that restrict the production efficiency and popularization and application of marine counterweight pipes, and achieve controllable direction and speed tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

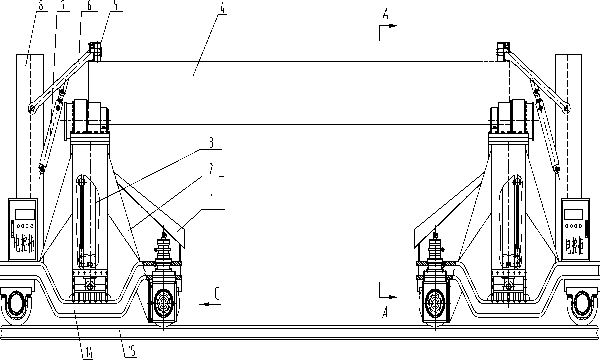

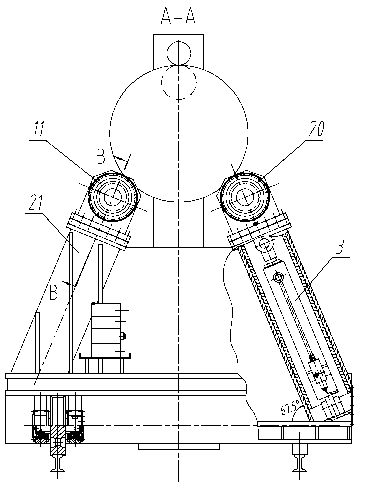

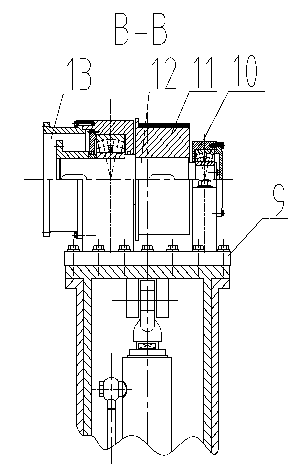

[0019] Such as figure 1 , figure 2 , image 3 As shown, the double inclined hydraulic coating trolley system of the marine pipeline concrete counterweight of the present invention mainly includes two opposite coating trolleys and a linear motion system for the coating trolleys to travel, and the coating trolleys are controlled by a height adjustment system , a rotary motion system, and a pipeline compression system, the height adjustment system is located in the middle of the coating trolley, the rotary motion system is set on the top of the height adjustment system, and the rotary motion system includes two tubes that are set on the top of the height adjustment system to support the pipeline Supporting wheels (11, 20), the pipeline pressing system is set on the side of each coating trolley away from the pipeline, and the linear motion system is located at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com