Cement clinker large bag packaging machine

A technology of cement clinker and packaging machine, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of poor filling measurement accuracy, high labor intensity, slow filling speed, etc., and achieves high filling accuracy, The effect of high degree of automation and accelerated filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

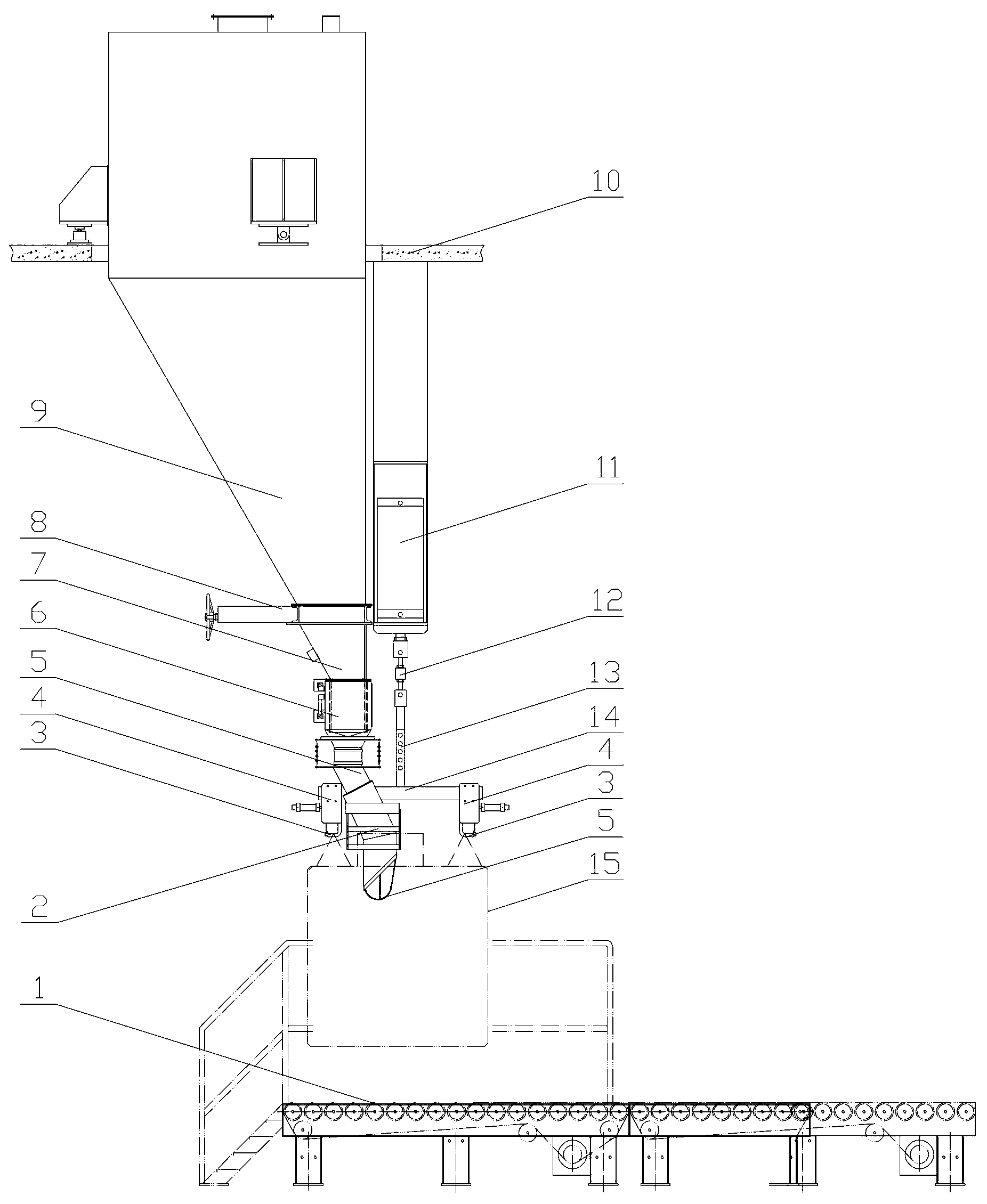

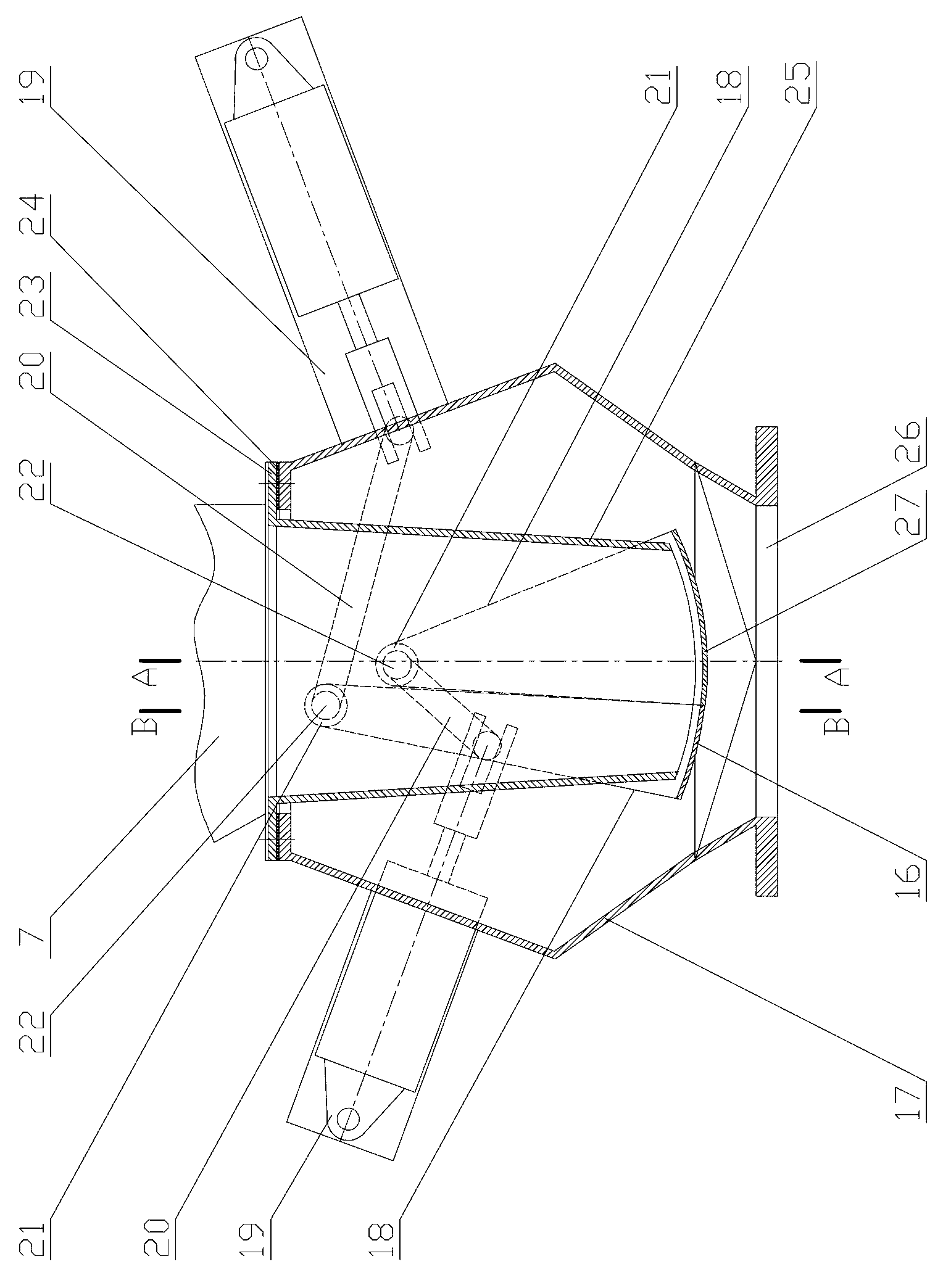

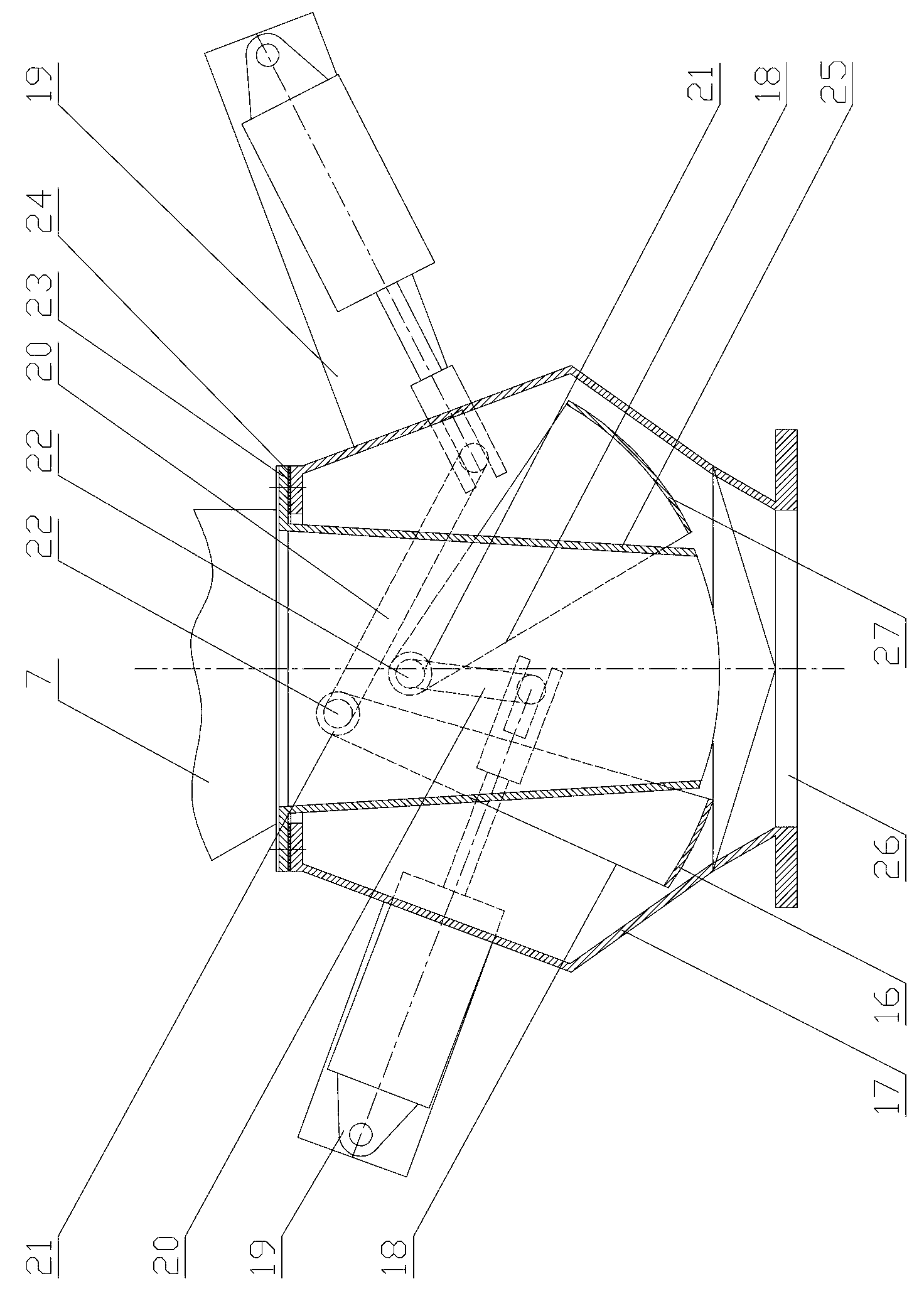

[0020] see Figure 1 to Figure 8 , the present invention comprises feed bin 9, and feed bin 9 is fixed on floor slab 10 (this floor slab 10 is the floor slab of the second floor of the installation site, and during specific installation, feed bin is installed on the second floor floor), and feed bin 9 bottoms are docked successively There is a hopper 7, a flow control valve and a double-layer filling casing 5, and a screw gate 8 is installed between the silo 9 and the hopper 7. An automatic bag clamping device 2 is installed on the double-layer filling casing 5, and a roller conveyor 1 is arranged below the double-layer filling casing 5. On the floor 10, a lifting device 11 is installed on the right side of the feed bin 9, and a connecting rod 13 is installed at the bottom of the lifting device 11, and an electronic weighing device 12 is arranged on the connecting rod 13. The bottom of the connecting rod 13 is hoisted with a cross-shaped hanger 14 located on one side of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com