Liquid crystal panel cartridge

A liquid crystal panel cassette and end face technology, which is applied to the packaging of vulnerable items, internal accessories, and types of packaged items, can solve the problems of liquid crystal panel collisions, increased production time and cost, and the inability to standardize mass production, etc., to prevent displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

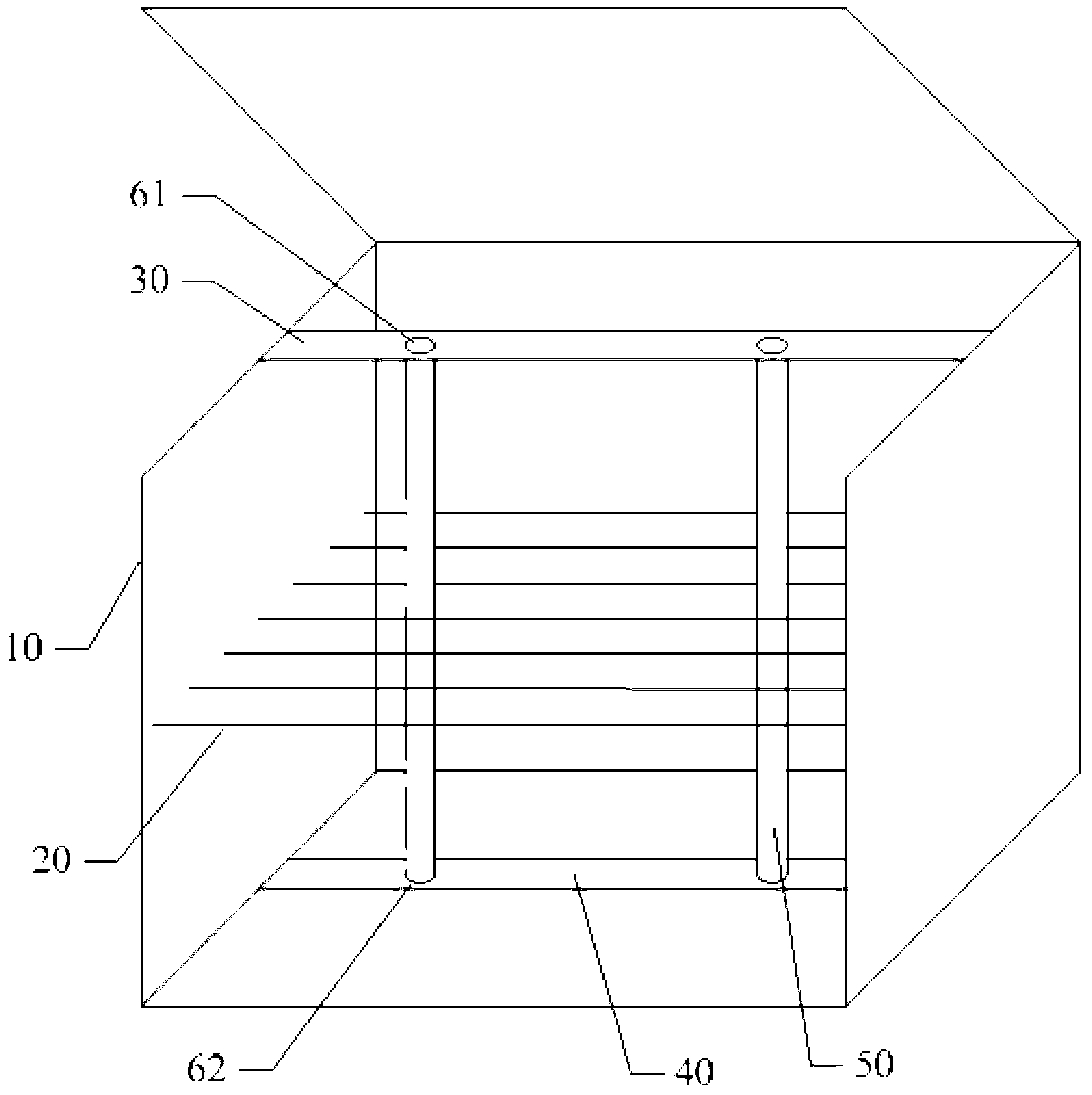

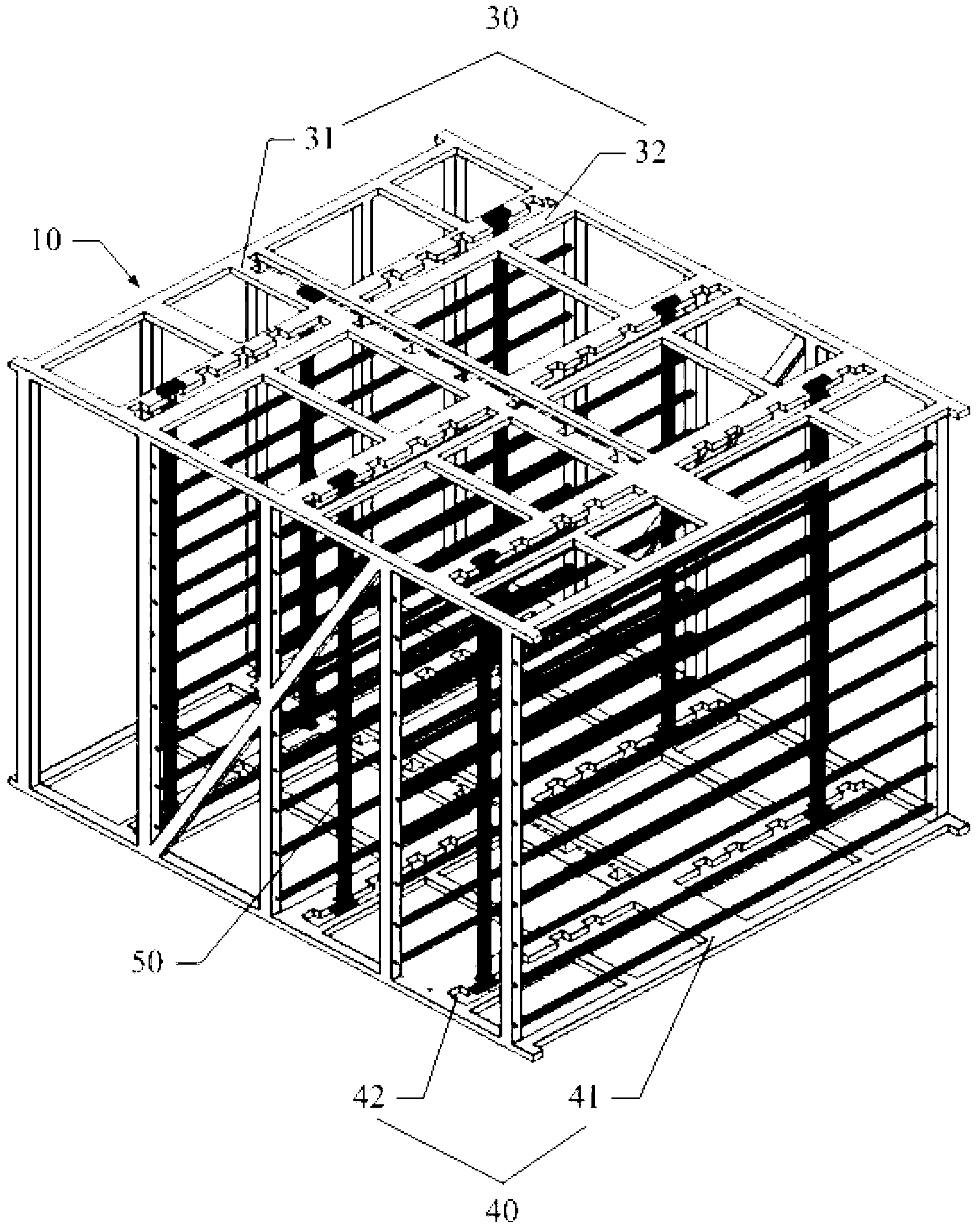

[0021] like figure 1 as shown, figure 1 It is a structural schematic diagram of the first embodiment of the liquid crystal panel cassette of the present invention.

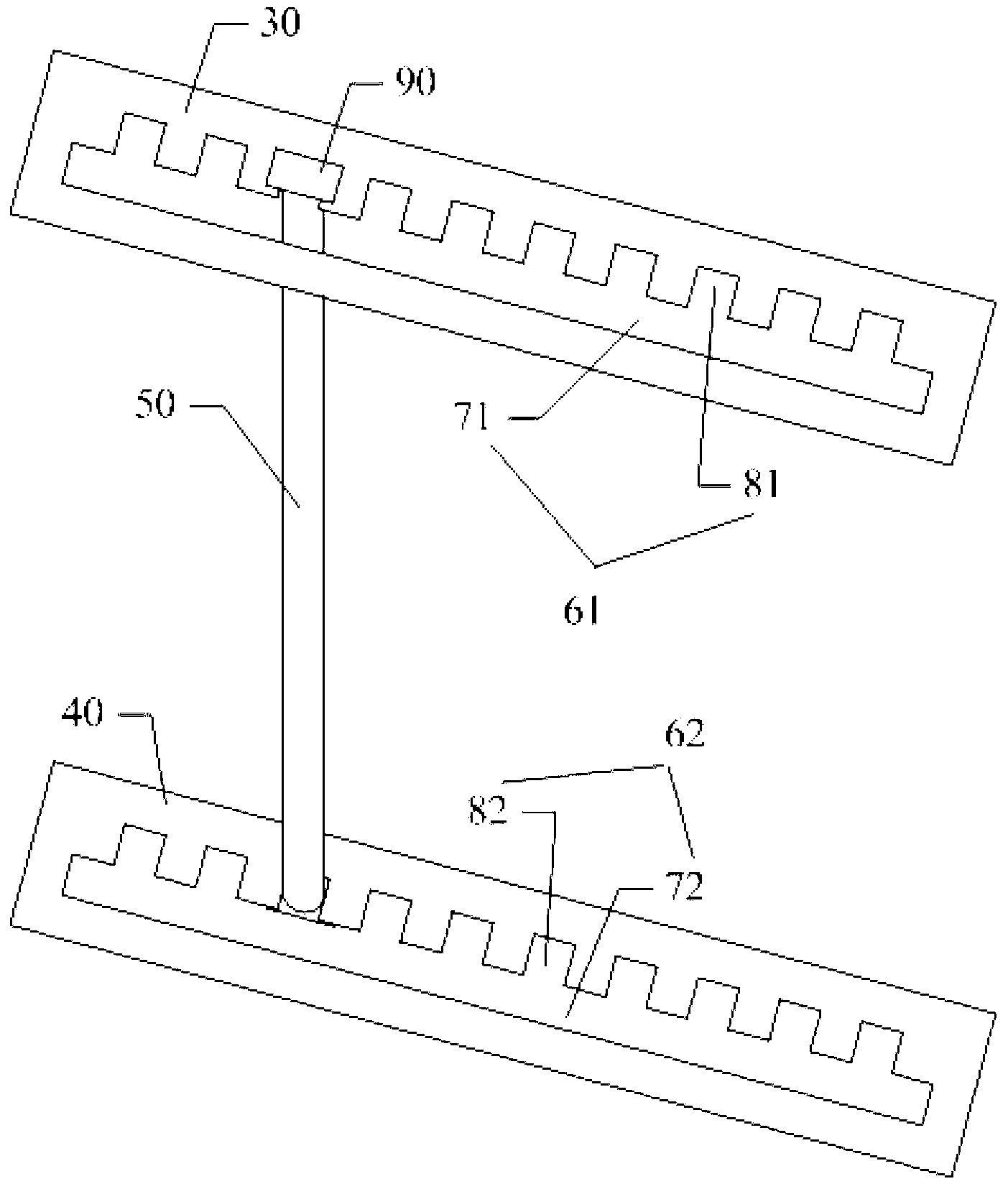

[0022] The liquid crystal panel cassette mentioned in this embodiment includes a box body 10. A support member 20 for supporting the liquid crystal panel (not shown in the figure) is arranged inside the box body 10. At least one upper positioning The lower end surface of the plate 30 is provided with at least one lower positioning plate 40 correspondingly, and at least one limiting strip 50 is detachably connected between the upper positioning plate 30 and the lower positioning plate 40 . When the size of the liquid crystal panel is small, after being placed on the support member 20, it cannot be well clamped on the side wall of the box body 10, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com