Automatic storing-and-taking method and device for dense three-dimensional warehouse goods shelf

An automatic access and shelf technology, which is applied in the field of storage and retrieval, can solve the problems of high energy consumption of the storage and storage system, paralysis of the storage and storage system, and the inability of goods to enter and leave the warehouse, so as to achieve flexible operation and shorten the time of entering and leaving the warehouse , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

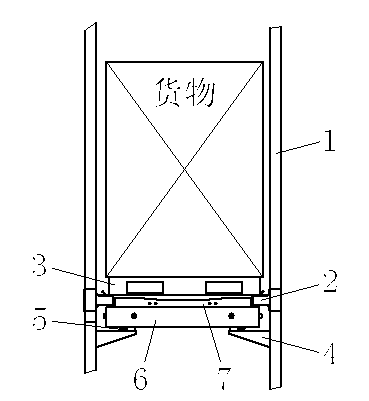

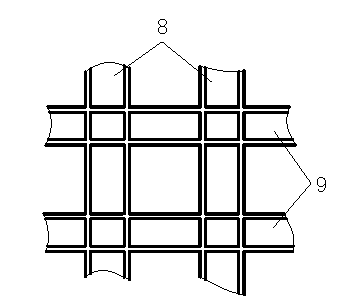

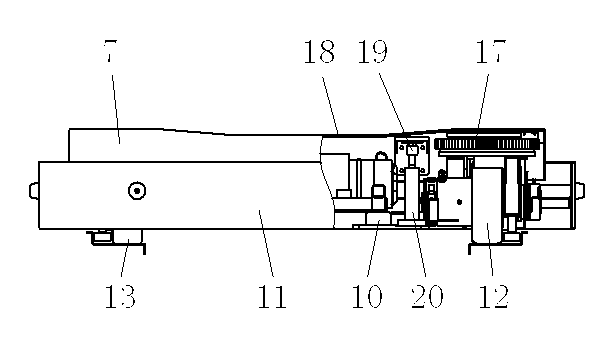

[0025] Embodiments of the present invention: an automatic access method for dense vertical warehouse shelves, such as figure 1 and figure 2 shown. The method is to set pallet support beams on the dense vertical warehouse shelves, and pallets are placed on the pallet support beams, and one pallet is used as a basic storage unit; track support blocks are provided on the dense vertical warehouse shelves below the pallet support beams, A track is laid on the track support block; at least one transfer car is provided on the track, and a lifting assembly is provided on the transfer car. The lifting assembly can lift the pallet together with the goods on the pallet to realize automatic storage and retrieval of the goods. The track forms a criss-cross orthogonal track network between the dense vertical warehouse shelves, and at least one layer of ortho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com