Glass substrate cutting system

A glass substrate and cutting system technology, applied in glass cutting devices, glass manufacturing equipment, conveyors, etc., can solve the problems of scrapped finished glass substrates, scratches on cutting surfaces, easy jumping or sliding, etc., to achieve increased contact area, The force is uniform and stable, and the effect of avoiding being scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

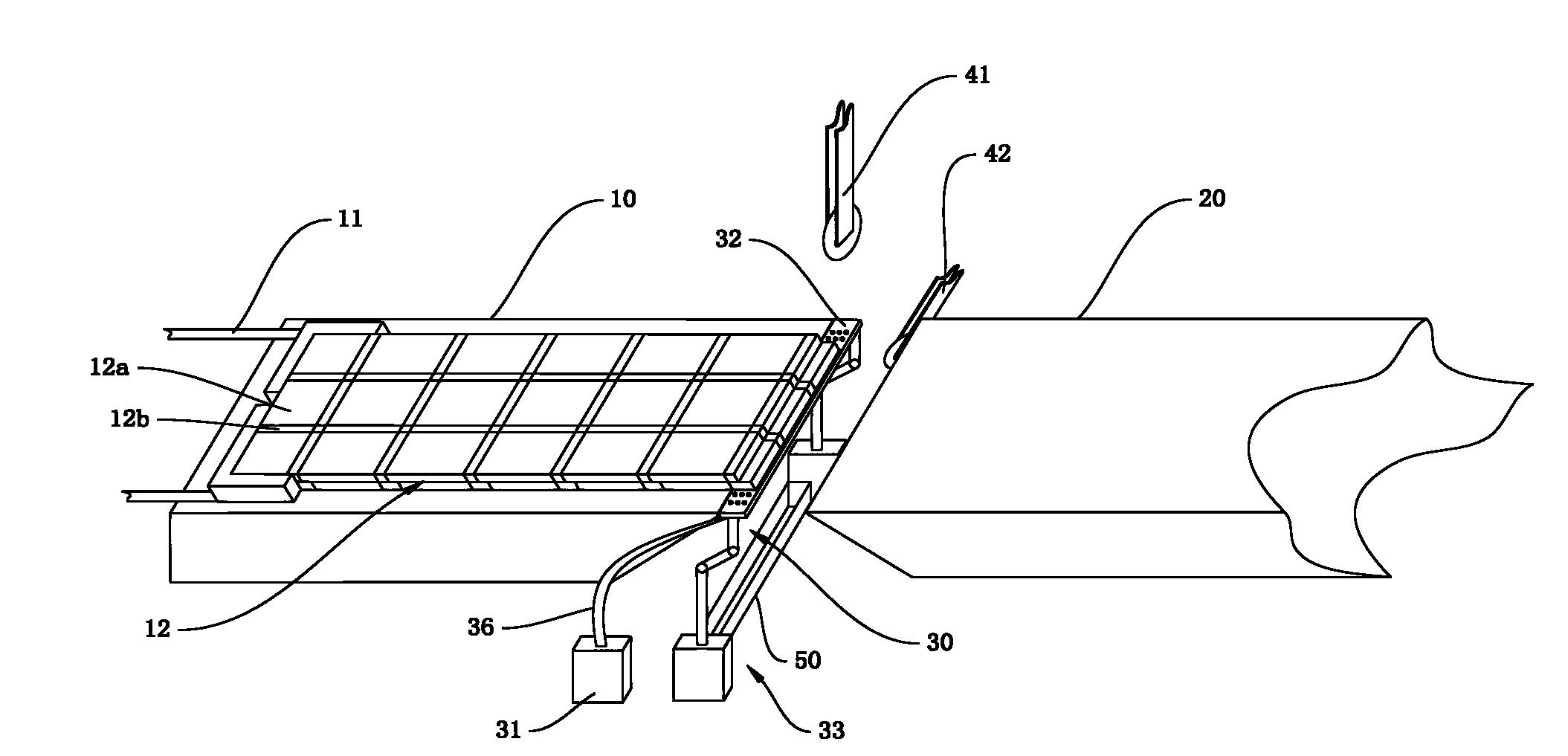

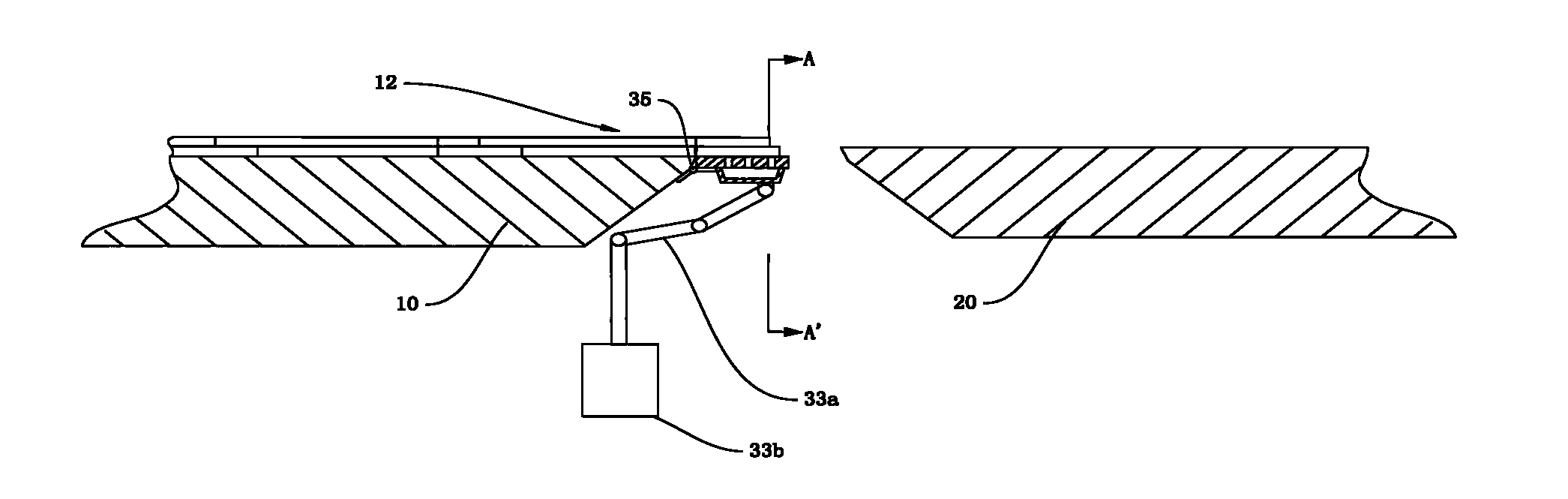

[0043] In this example, if Figure 7 As shown, the suction plate 32 of this unloading device 30 can also not be directly hinged to the front end of the upstream suction table 10, but moves as a whole under the drive of the mechanical arm 33a, so as to complete the separation of the suction residual part 12b from the original glass substrate 12 and unload.

[0044] In addition, a roller 70 is added above the glass substrate 12 , opposite to the lower cutter head 42 , so that the cutting sequence of the upper cutter head 41 and the lower cutter head 42 can be adjusted to meet the needs of glass substrates 12 of different shapes. For example, the CF board of the glass substrate 12 can be cut by using the lower cutter head 42 first. A pair of balancing forces keeps the glass substrate 12 from being damaged. After the cutting of the CF board is completed, the suction plate 32 is raised to be flush with the surface of the upstream suction table 10, and the upper cutter head 41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com