Device and method for producing sodium methoxide through recompression of mechanical steam

A technology for vapor recompression and production equipment, which can be used in organic chemistry, metal alcohol preparation, climate sustainability, etc., and can solve problems such as high energy consumption and complex process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

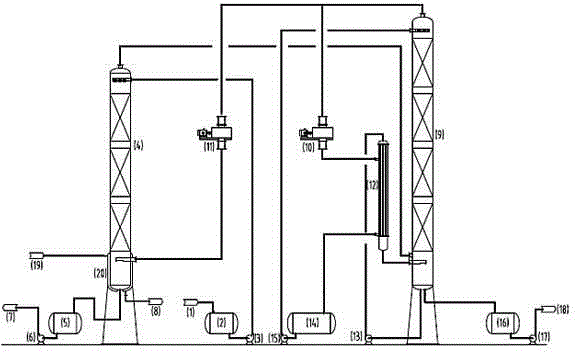

[0012] Refer to attached figure 1 , describe in detail the sodium methoxide production process and method provided by the invention. The working process of the device is as follows:

[0013] Turn on the raw material pump 3, the temperature from the lye storage tank 2 is 40°C, containing 10%H 2 O, 70%CH 3 The raw material 1 of OH and 20% NaoH is sent to the liquid phase inlet at the top of the sodium methoxide reaction tower 4 through the raw material pump 3, and flows from top to bottom. Afterwards, it flows from bottom to top after being mixed with 99.9% methanol vapor from the gas phase inlet at the bottom of the sodium methoxide reaction tower 4, and the NaOH in the raw material in the sodium methoxide reaction tower 4 chemically reacts with methanol to generate sodium methoxide and H 2 O, the sodium methoxide product with a sodium methoxide mass concentration of 28% is obtained from the liquid phase outlet at the bottom of the sodium methoxide reaction tower 4, and is d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap