Oxidative polymerization type rust-proof anti-corrosion adhesive tape

An oxidative polymerization type and corroded adhesive technology, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of fit, limited sealing, labor costs, and low construction efficiency, so as to benefit the environment. The effect of high economic benefit and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first step is to make the compound. In terms of mass percentage, 28% of linseed oil, 33% of aluminum hydroxide, 22% of magnesium hydroxide and 12% of organic bentonite are mixed.

[0020] In the second step, the compound is impregnated into 5% polyester non-woven fabric, and the polyester non-woven fabric is kept in the middle layer; the thickness of the anti-rust and anti-corrosion adhesive tape is kept at 1.1 mm.

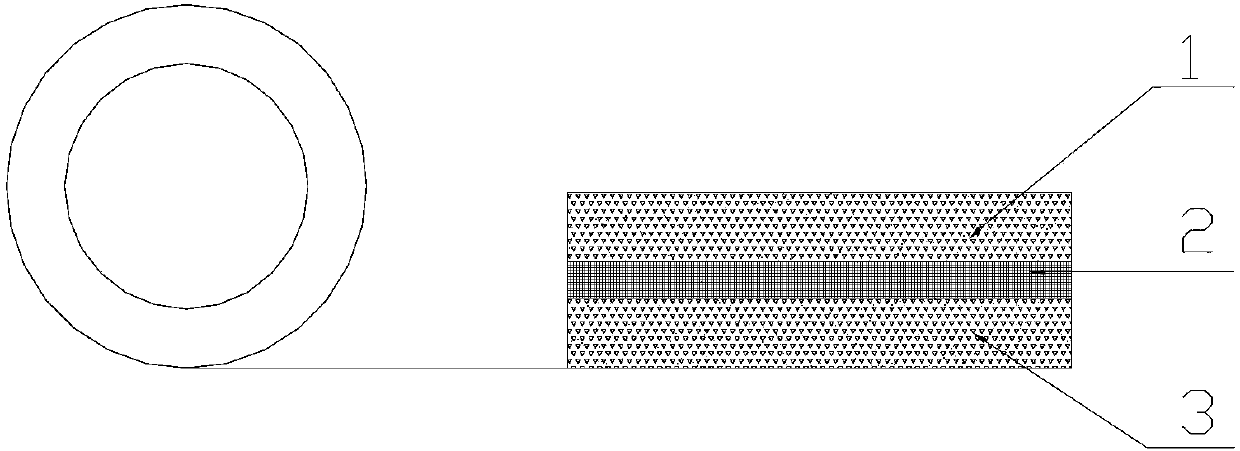

[0021] The third step is through oxidative polymerization and drying to form such as figure 1 Oxidative polymerized anti-rust and anti-corrosion adhesive tape shown.

[0022] The soaking process is as follows: the above-mentioned various ingredients are added and melted, and the polyester non-woven fabric is put into it, soaked to a certain thickness, and then taken out and dried.

Embodiment 2

[0024] The difference from Example 1 is:

[0025] The first step is to make the compound. In terms of mass percentage, 28% of linseed oil, 33% of aluminum hydroxide, 22% of magnesium hydroxide and 10% of organic bentonite are mixed.

[0026] In the second step, the compound is impregnated into 7% polyester non-woven fabric, and the polyester non-woven fabric is kept in the middle layer; the thickness of the anti-rust and anti-corrosion adhesive tape is kept at 1.1 mm.

[0027] The third step is formed by oxidative polymerization and drying figure 1 Oxidative polymerized anti-rust and anti-corrosion adhesive tape shown.

[0028] The soaking process is as follows: the above-mentioned various ingredients are added and melted, and the polyester non-woven fabric is put into it, soaked to a certain thickness, and then taken out and dried.

Embodiment 3

[0030] The first step is to make the compound. In terms of mass percentage, 28% of linseed oil, 33% of aluminum hydroxide, 21% of magnesium hydroxide and 12% of organic bentonite are mixed.

[0031] The second step is to impregnate the compound into 6% polyester non-woven fabric, keep the polyester non-woven fabric in the middle layer; keep the anti-rust and anti-corrosion adhesive tape at a thickness of 1.1mm.

[0032] The third step is formed by oxidative polymerization and drying figure 1 Oxidative polymerized anti-rust and anti-corrosion adhesive tape shown.

[0033] The soaking process is as follows: the above-mentioned various ingredients are added and melted, and the polyester non-woven fabric is put into it, soaked to a certain thickness, and then taken out and dried.

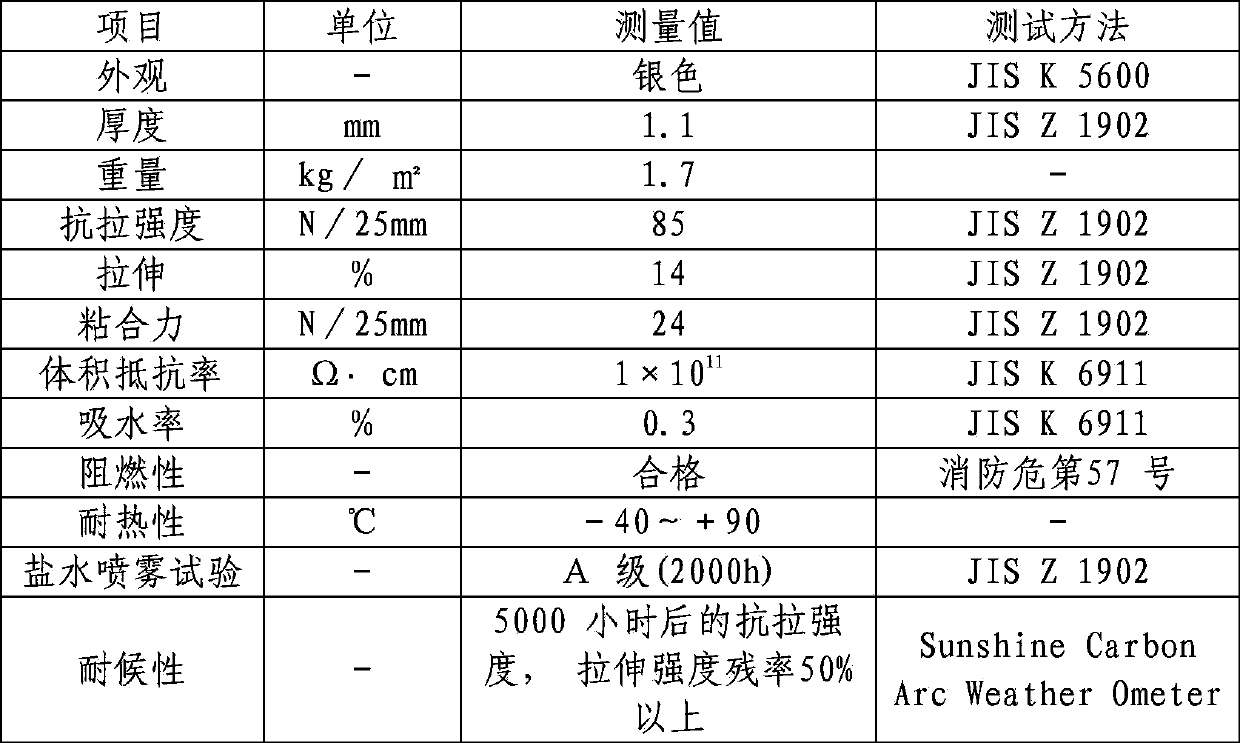

[0034] The anti-corrosion obtained in the above-mentioned examples is measured, and the measurement results are shown in Table 1

[0035] Table 1 Characteristics of oxidative polymerization type antir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com