Adhesive composition, adhesive layer and adhesive sheet

A composition and adhesive technology, applied in the field of adhesive layer and adhesive composition, to achieve the effects of excellent wettability and preventing the intrusion of air bubbles and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

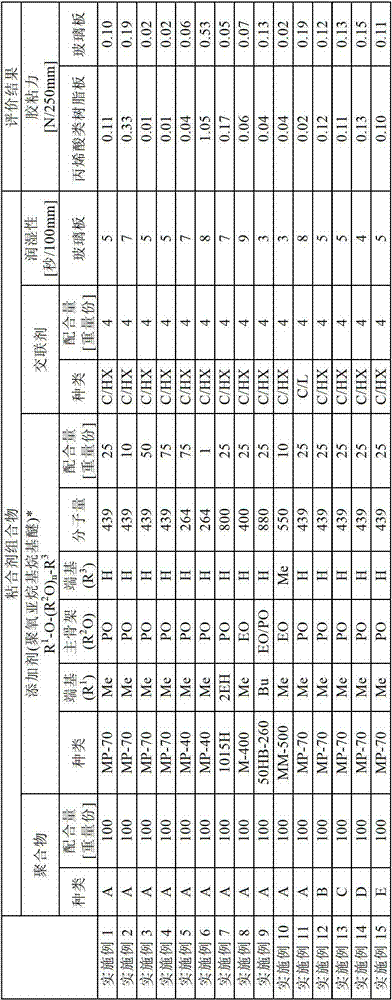

Embodiment 1

[0127] Using 100 parts by weight (solid content) of the above-mentioned acrylic polymer (A), add 25 parts by weight of polyoxypropylene monomethyl ether with a molecular weight of 439 (manufactured by Kao Corporation, trade name "Smack MP-70"), 4 parts by weight 1 part by weight of the isocyanurate form of hexamethylene diisocyanate (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name "Coronet HX") as a crosslinking agent and 0.015 parts by weight of dioctyltin dilaurate (Tokyo Seiki Co., Ltd. Chemical (Tokyo Fine Chemical Co., Ltd., trade name "OL-1") was diluted with toluene to a solid content concentration of 29% by weight, and then stirred to obtain a binder composition solution.

[0128] The adhesive composition solution was applied to "Lumira-S10" manufactured by Toray Co., Ltd., which is a polyethylene terephthalate (PET) film with a thickness of 38 μm, and dried at 130° C. for 30 seconds, thereby The solvent was removed to form an adhesive layer (thickne...

Embodiment 2

[0130] A pressure-sensitive adhesive sheet was obtained in the same manner as in Example 1 except that the compounding amount of polyoxypropylene monomethyl ether (manufactured by Kao Corporation, trade name "Smack MP-70") having a molecular weight of 439 was set to 10 parts by weight. .

Embodiment 3

[0132] A pressure-sensitive adhesive sheet was obtained in the same manner as in Example 1, except that the compounding amount of polyoxypropylene monomethyl ether (manufactured by Kao Corporation, trade name "Smack MP-70") having a molecular weight of 439 was set to 50 parts by weight. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com