Laser processing apparatus

A laser processing and laser technology, applied in metal material coating process, gaseous chemical plating, application, etc., can solve the problems of substrate deflection, processing position and focus shift, damage, etc., and achieve the effect of reducing deflection

Inactive Publication Date: 2013-09-11

V TECH CO LTD

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, when the substrate is heated, it is expected that the substrate will be warped due to thermal expansion, and the processing position and focus will be shifted, resulting in deterioration of processing quality.

In addition, when the amount of deflection increases, it is likely that the surface of the substrate will come into contact with a part of the laser processing device to cause damage.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0064] 2. Variation

Embodiment approach )

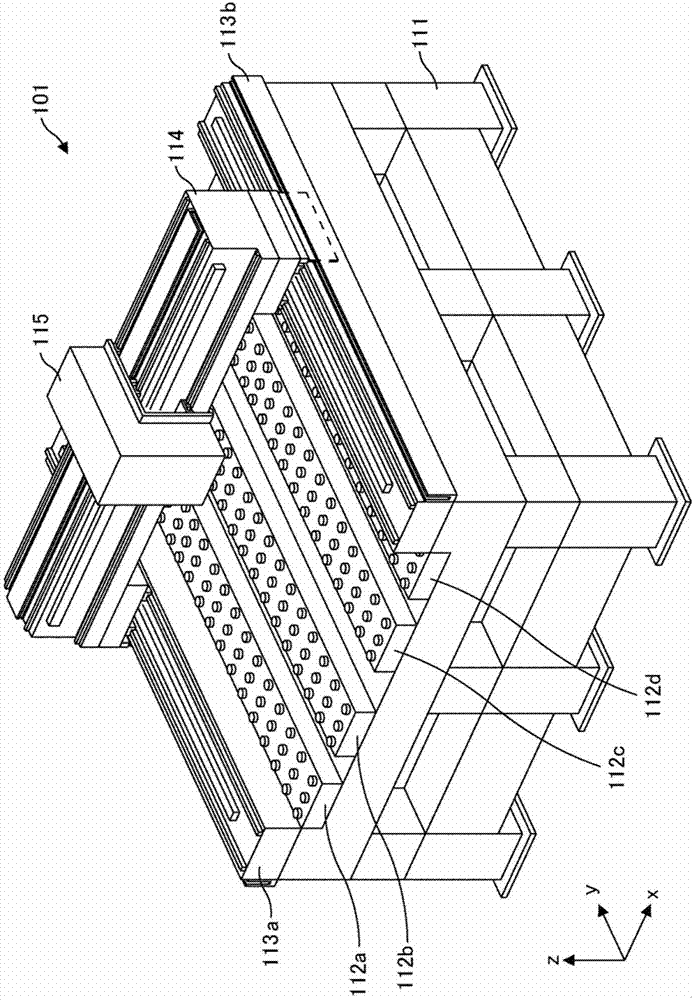

[0066] (Example of configuration of laser processing equipment)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

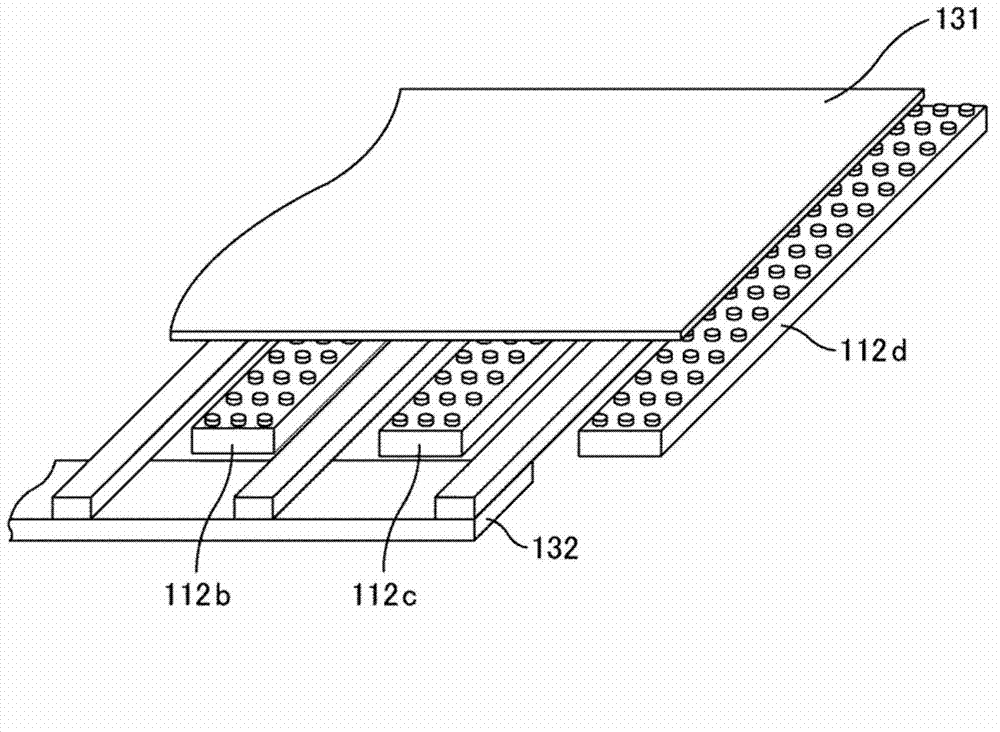

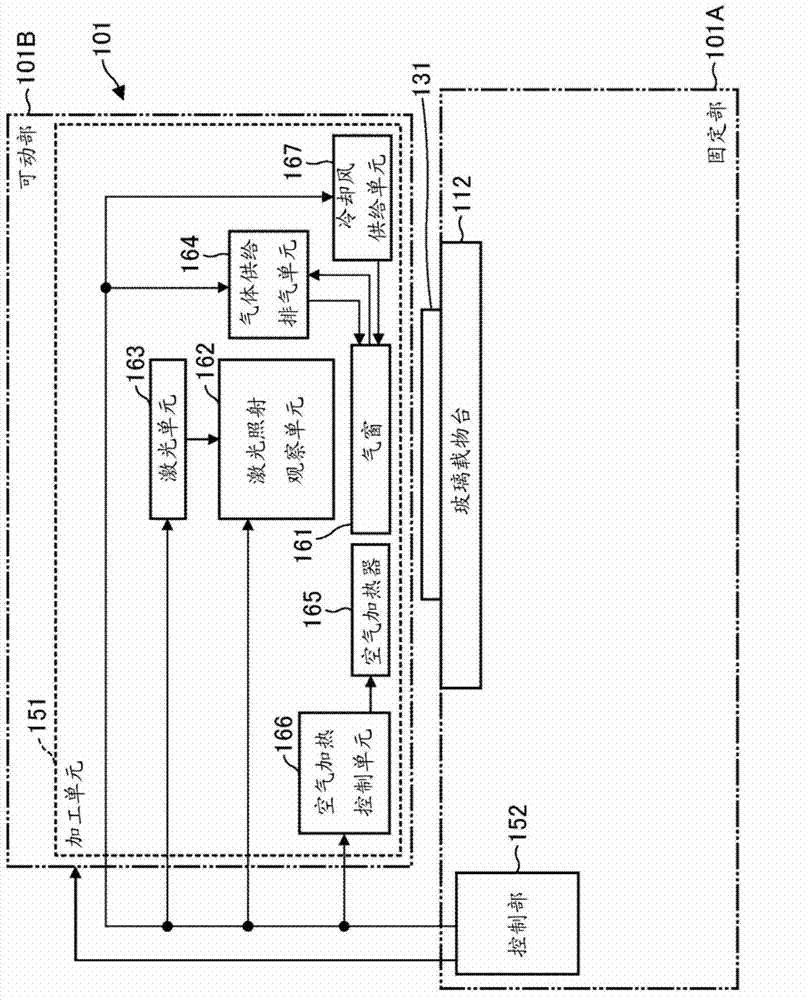

A laser processing apparatus is capable of reliably and highly efficiently heating nearby a processing part wherein the CVD processing is conducted and decreasing the deflexion of a processed object. In the laser processing apparatus (101) conducting the laser CVD processing, an air heater (165) supplies hot air to the processing part of a substrate (131) through an air window (161). The air window (161) keeps the CVD space nearby the processing part in a raw gas environment by virtue of supplying raw gas from a gas sucking and discharging unit (164). An air cooling unit (167) supplies cooling air to the periphery nearby the processing part of the substrate (131) through the air window (161). A laser unit (163) irradiates laser onto the processing part through a laser irradiation observation unit (162) and the air window (161). For example, the laser processing apparatus is applicable to laser repair devices.

Description

technical field [0001] The present invention relates to a laser processing device, in particular to a laser processing device for performing laser CVD (Chemical Vapor Deposition) processing. Background technique [0002] Currently, laser processing devices that use laser CVD (Chemical Vapor Deposition) to correct wiring defects on substrates used in display panels such as LCD (Liquid Crystal Display) panels and organic EL (Electro-Luminescence) panels are widespread. [0003] In a laser processing device using the laser CVD method, a raw material gas is supplied to the vicinity of the portion where the wiring on the substrate to be processed is corrected, and laser light is irradiated to the corrected portion on the substrate, and the raw material activated by the energy of the laser The gas acts as a film and accumulates in the corrected portion, thereby correcting the wiring on the substrate. However, when the raw material gas is supplied to the surface of the substrate, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C16/48

CPCA01G9/246A01G9/247A01G9/26A01G18/60

Inventor 中塚敬一

Owner V TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com