Uniform coating structure

A uniform coating, empty roller technology, applied in the direction of coating, device for coating liquid on the surface, textile and papermaking, etc., can solve the problem of different coating thickness, inconsistent coating performance of textiles, affecting clothing performance and other problems to achieve a uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

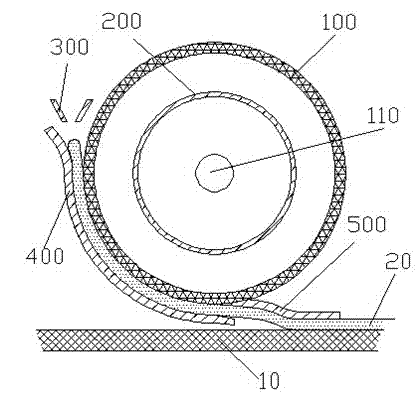

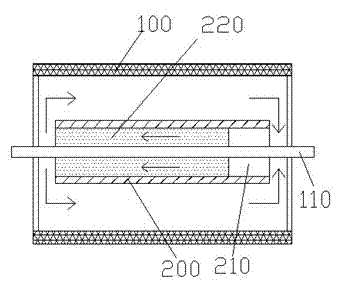

[0018] refer to figure 1 , in this embodiment, the uniform coating structure includes a hollow roller 100 and a rotating shaft 110 arranged at the center of the hollow roller 100, the rotating shaft 110 is driven to rotate by a driving device, and the barrel of the hollow roller 100 The body is surrounded by an arc-shaped shaping sheet 400, and the space between the shaping sheet 400 and the body of the hollow roller 100 forms arc-shaped gaps at equal intervals, and the entrance and exit of the arc-shaped gap are arranged in sequence In the direction of rotation of the hollow roller 100, the entrance of the arc-shaped gap is provided with a coating extrusion nozzle 300, and the exit of the arc-shaped gap is provided with a scraper 500, and the edge of the scraper 500 is in contact with the hollow The cylinder body of the roller 100 is tangent, and the blade back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com