Universal coupling for implementing synchronous movement of special-shaped large-span rolling doors

A synchronous operation, universal coupling technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of affecting the construction speed, delaying the construction progress, increasing the total cost, etc., to achieve a small number and achieve synchronization the effect of reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

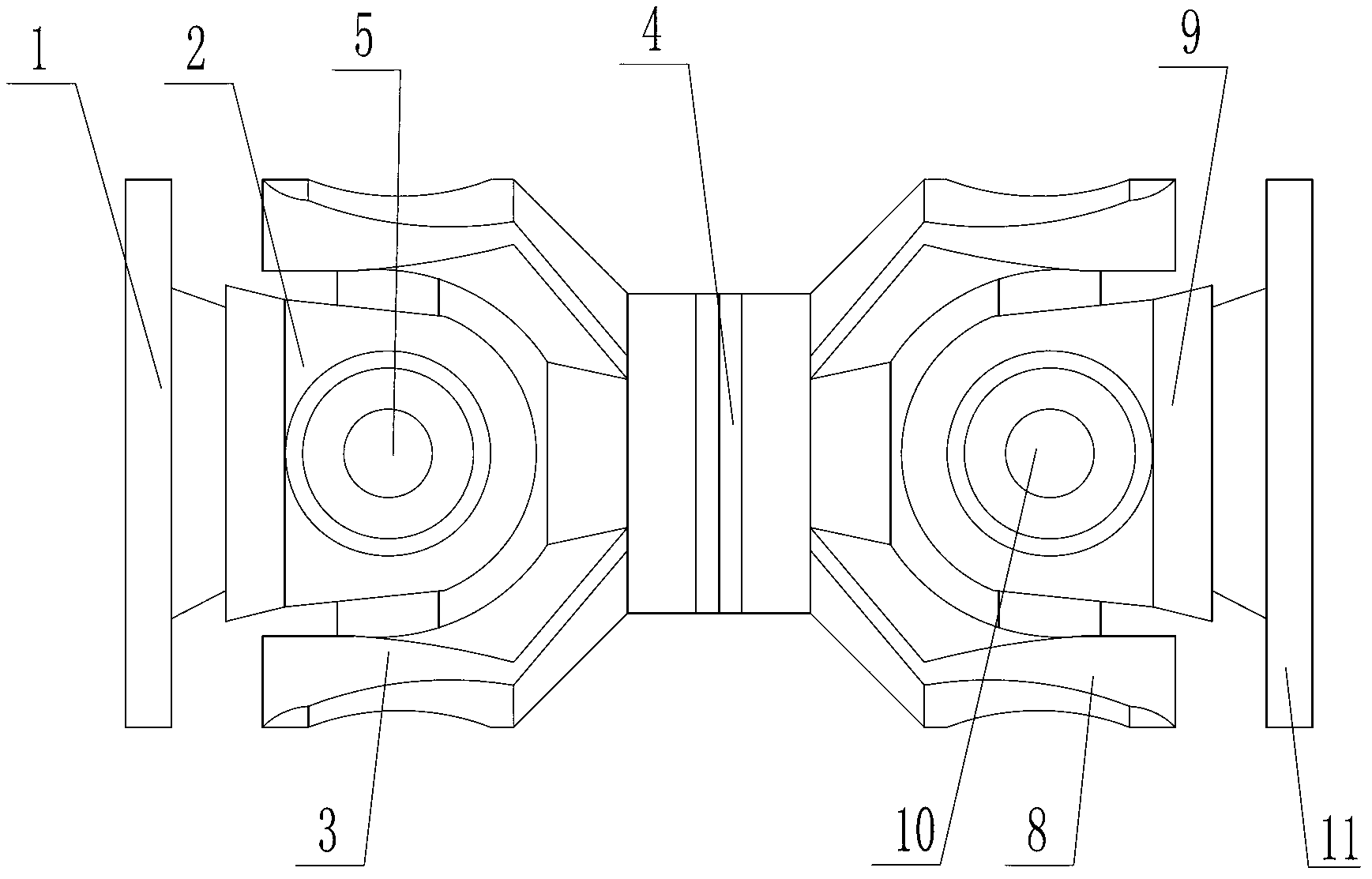

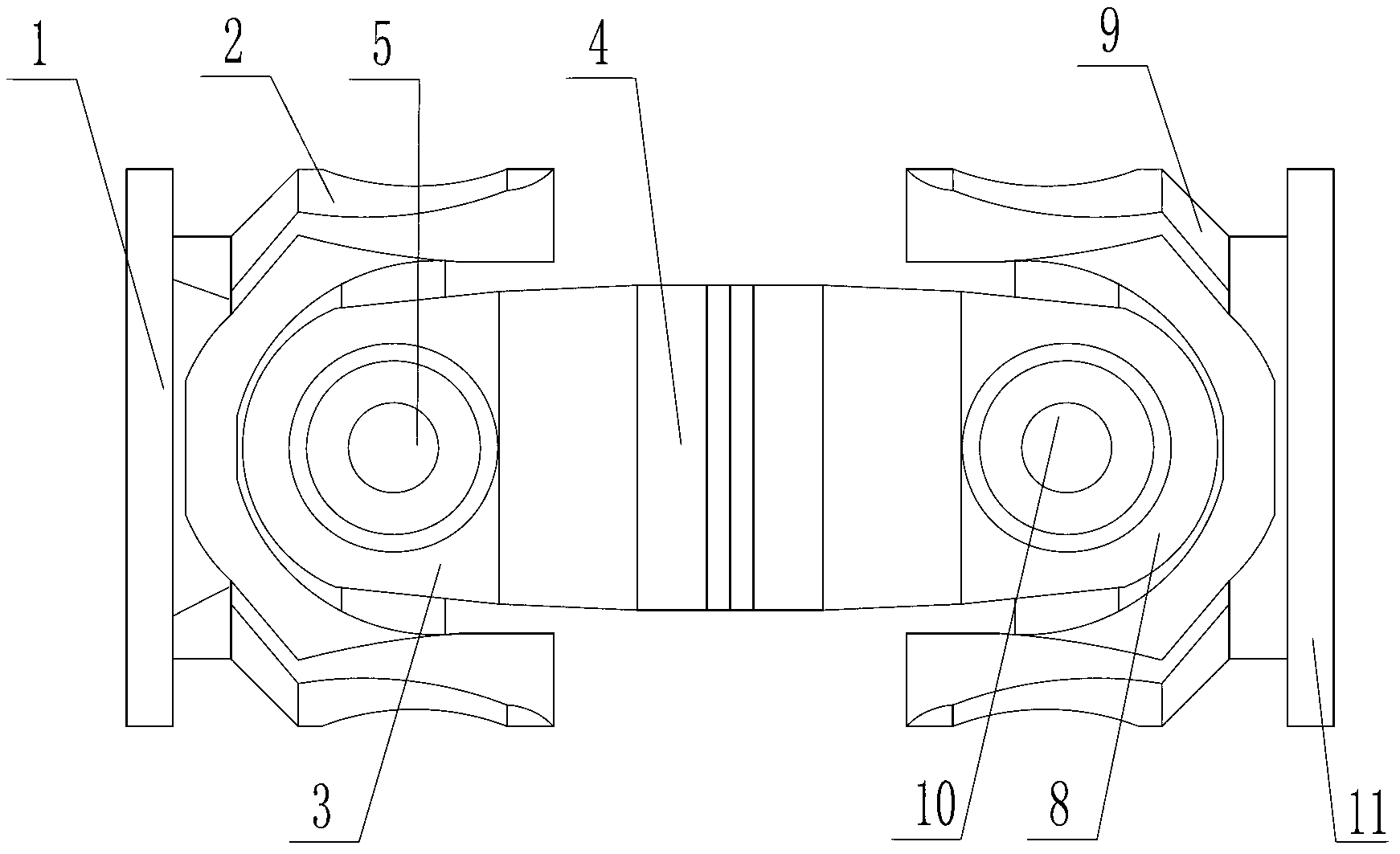

[0032] Such as figure 1 with figure 2 A specific embodiment of the invention is shown. In this embodiment, a universal joint of the present invention that realizes the synchronous operation of special-shaped large-span rolling doors includes:

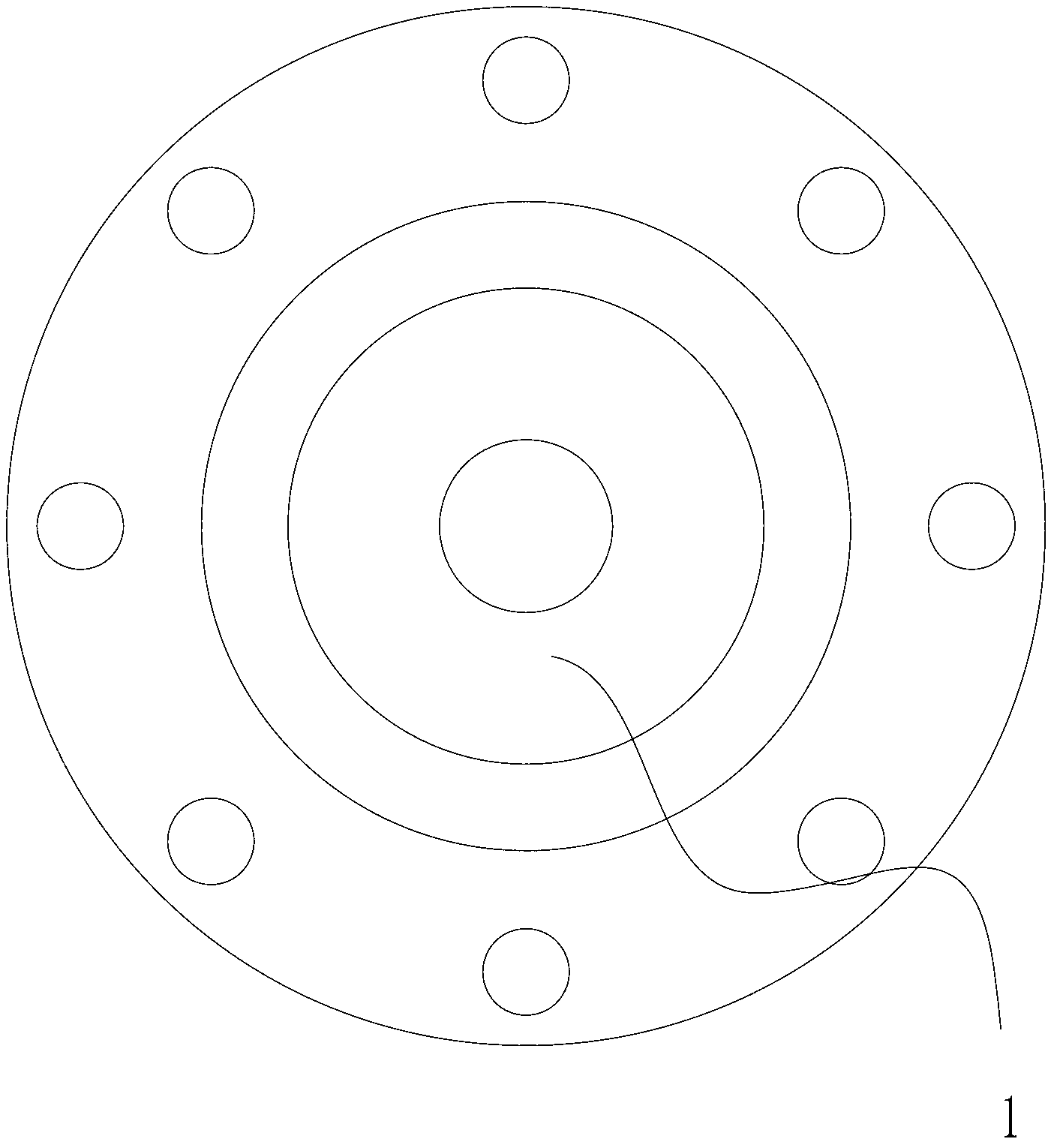

[0033] a first connecting flange 1 with one end connected to the first roller shaft 6 connected to the rolling door;

[0034] The first flange yoke 2, the second flange yoke 3, and the first cross shaft 5, the first flange yoke 2 is connected to the other end of the first connecting flange 1, the first flange yoke 2 Arranged alternately with the second flange fork 3 and connected via the first cross shaft 5;

[0035] Transmission shaft 4, one end of which is connected to the second flange yoke 3;

[0036] The third flange yoke 8 is connected with the other end of the transmission shaft 4;

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com