An environmentally friendly particle circulation system suitable for drilling

A circulatory system and particle technology, used in drilling equipment, earth-moving drilling, flushing wells, etc., can solve the problems of many mud leakage points, complicated installation, inconvenient installation and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

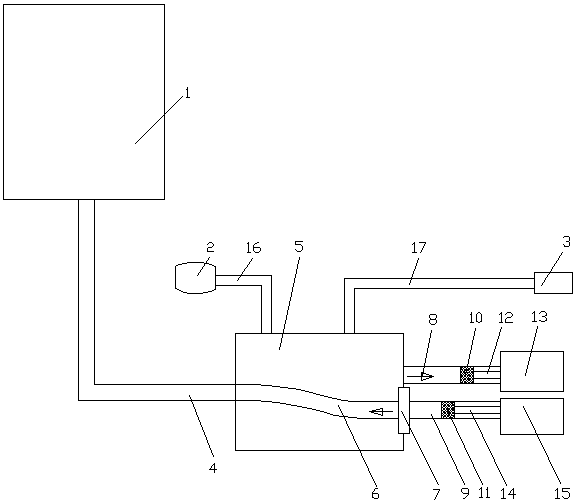

[0048] see figure 1 and figure 2 , an environmentally friendly particle circulation system suitable for drilling, including a drilling floor 1, an injection device and a recovery device, the injection device includes a slurry pump 2, a screw conveyor 3 and a particle mixing unit connected to the drilling riser through a high-pressure pipeline 4 Hopper 5, the particle mixing hopper 5 is provided with a reversing pipe 6, the reversing pipe 6 is connected with a swing hydraulic cylinder 7 that drives the reversing pipe 6 to swing left and right, the particle mixing hopper 5 is connected with a first delivery cylinder 8 and The second conveying cylinder 9, the first conveying cylinder 8 is provided with a first piston 10, the second conveying cylinder 9 is provided with a second piston 11, and the first piston 10 is connected to the first hydraulic cylinder 13 through the first piston rod 12 , the second piston 11 is connected to the second hydraulic cylinder 15 through the seco...

Embodiment 2

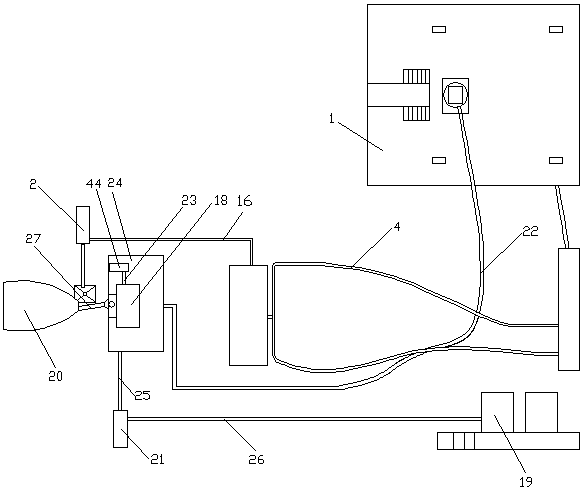

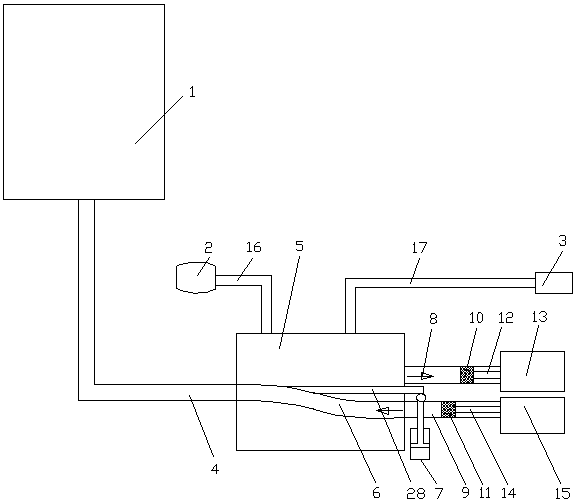

[0051] see figure 1 , image 3 and Figure 4 , an environmentally friendly particle circulation system suitable for drilling, including a drilling floor 1, an injection device and a recovery device, the injection device includes a slurry pump 2, a screw conveyor 3 and a particle mixing unit connected to the drilling riser through a high-pressure pipeline 4 Hopper 5, the particle mixing hopper 5 is provided with a reversing pipe 6, the reversing pipe 6 is connected with a swing hydraulic cylinder 7 that drives the reversing pipe 6 to swing left and right, the particle mixing hopper 5 is connected with a first delivery cylinder 8 and The second conveying cylinder 9, the first conveying cylinder 8 is provided with a first piston 10, the second conveying cylinder 9 is provided with a second piston 11, and the first piston 10 is connected to the first hydraulic cylinder 13 through the first piston rod 12 , the second piston 11 is connected to the second hydraulic cylinder 15 thro...

Embodiment 3

[0055] see figure 1 , Figure 4 and Figure 8 , an environmentally friendly particle circulation system suitable for drilling, including a drilling floor 1, an injection device and a recovery device, the injection device includes a slurry pump 2, a screw conveyor 3 and a particle mixing unit connected to the drilling riser through a high-pressure pipeline 4 Hopper 5, the particle mixing hopper 5 is provided with a reversing pipe 6, the reversing pipe 6 is connected with a swing hydraulic cylinder 7 that drives the reversing pipe 6 to swing left and right, the particle mixing hopper 5 is connected with a first delivery cylinder 8 and The second conveying cylinder 9, the first conveying cylinder 8 is provided with a first piston 10, the second conveying cylinder 9 is provided with a second piston 11, and the first piston 10 is connected to the first hydraulic cylinder 13 through the first piston rod 12 , the second piston 11 is connected to the second hydraulic cylinder 15 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com