Modular waste acid purifier

A purifier and modular technology, applied in the direction of chemical instruments and methods, control/manipulation systems, water treatment parameter control, etc., can solve the problems of many leakage points, heavy adsorbent workload, inconvenient operation, etc., to reduce the treatment level difference, achieving synchrony and accuracy, and improving synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

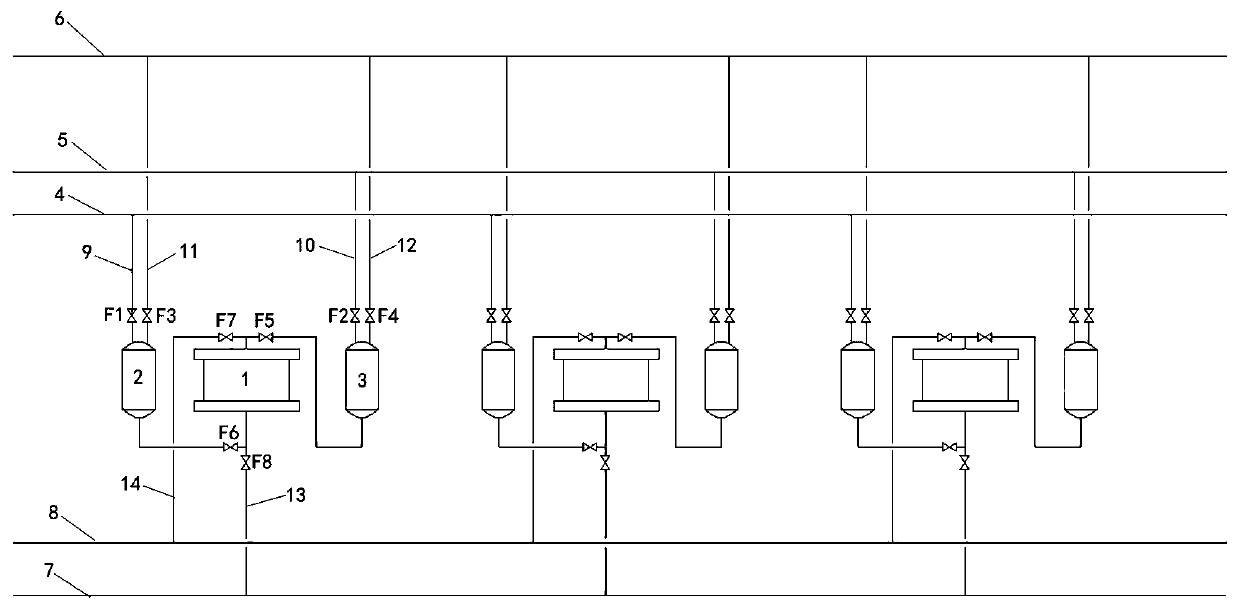

[0031] A modular waste acid purifier, such as figure 1 shown, including:

[0032] -N purification units (3 in this embodiment) arranged in parallel, each purification unit includes an adsorption separation module 1, a waste acid metering tank 2 and a pure water metering tank 3, the output of the waste acid metering tank 2 The mouth is connected with the waste liquid inlet at the lower end of the adsorption separation module 1 through a pipeline, and a valve F6 is arranged on the pipeline, and the liquid outlet of the pure water metering tank 3 is connected with the pure water inlet at the upper end of the adsorption separation module 1 through a pipeline, and the pipeline is provided with a valve F6. With valve F5;

[0033] - Common main pipe, including waste acid main pipe 4, pure water main pipe 5 and compressed air main pipe 6;

[0034]- The main outlet pipe, including the main pipe for purifying acid 7 and the main pipe for metal salt solution 8;

[0035] The upper part...

Embodiment 2

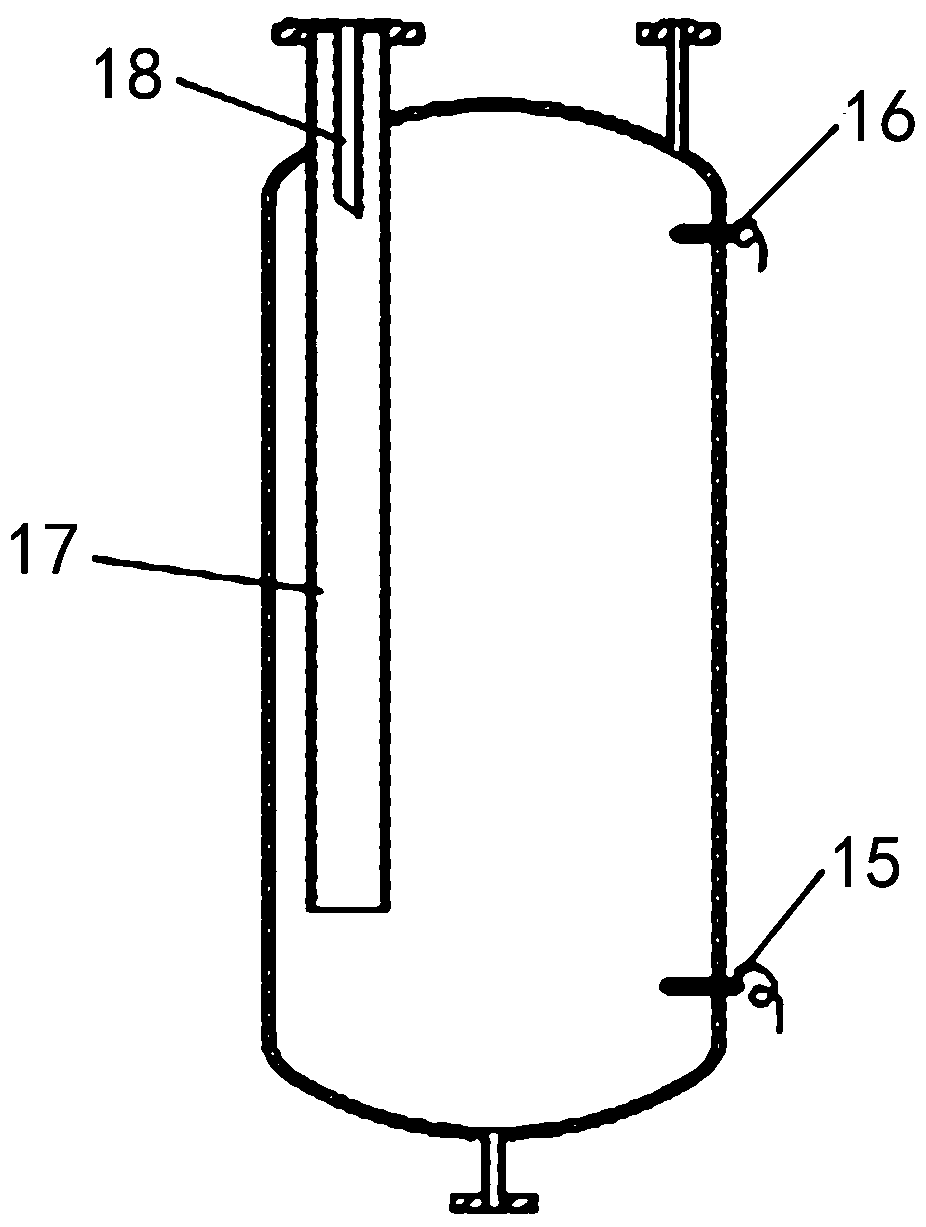

[0044] Such as figure 2 Shown is the tank structure of the waste acid metering tank 2 and the pure water metering tank 3 of the present invention, the waste acid metering tank 2 and the pure water metering tank 3 are all splash-proof metering tanks, and a low liquid level probe 15 is arranged in the tank And the high liquid level probe 16, the low liquid level probe 15 and the high liquid level probe 16 are connected with the liquid level controller. Taking the waste acid metering tank 2 as an example, during operation, the electronic control system controls the acid pump and valve F1 to open, and the waste acid main pipe 4 feeds the waste liquid into the waste acid metering tank 2. When the high liquid level probe 16 detects the liquid level, the The information is sent to the liquid level controller, and the liquid level controller controls valve F1 to close, ending the liquid intake of waste acid metering tank 2; the electronic control system controls valves F3, F6 and F7 ...

Embodiment 3

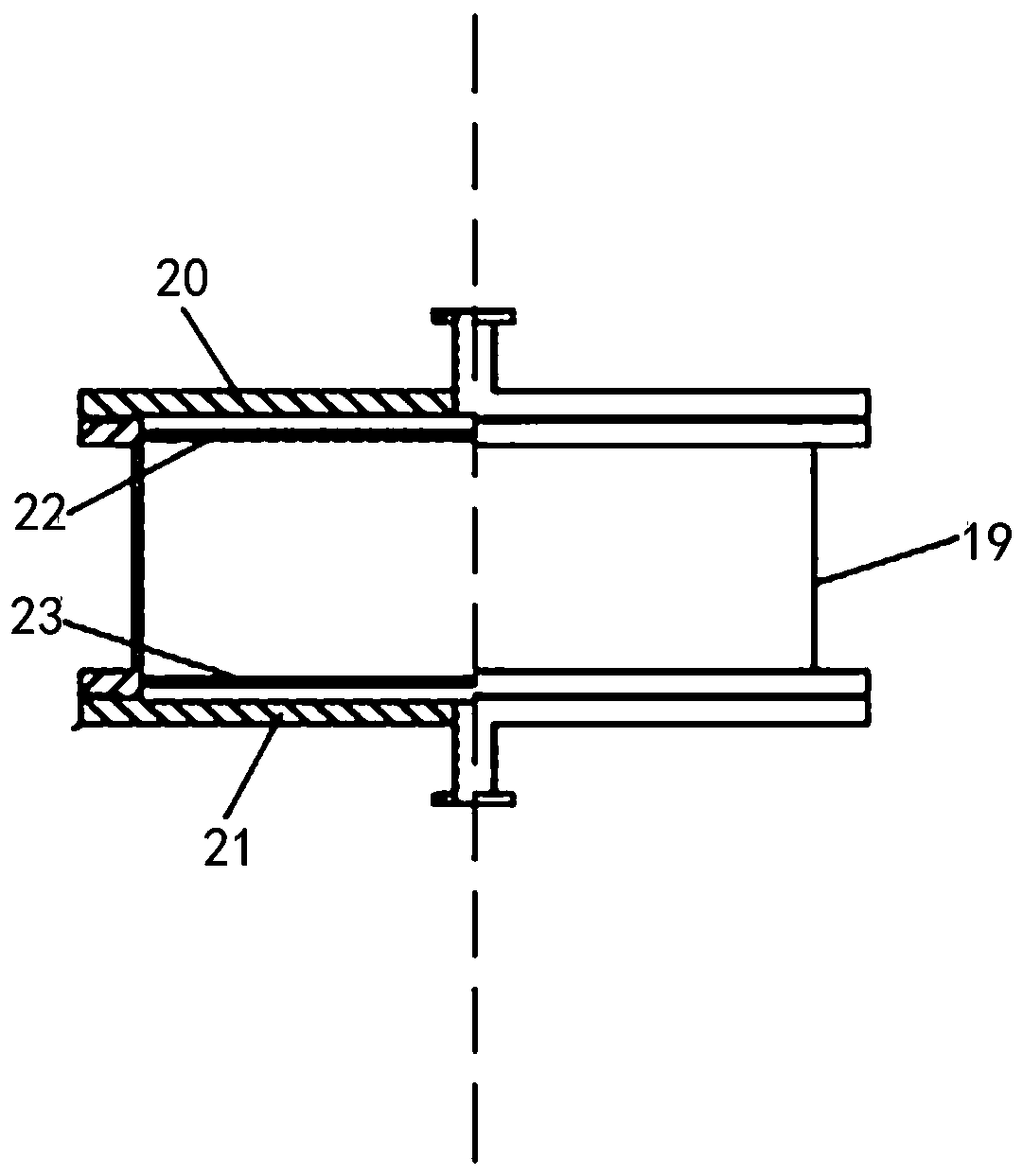

[0047] Such as image 3 Shown is the structure of the adsorption separation module 1 of the present invention. The adsorption separation module 1 is a cylindrical hollow container with a diameter-to-length ratio ≥ 1, including a cylinder body 19, an upper end cover 20 and a lower end cover 21. Inside the cylinder body 19 An upper porous water distribution plate 22 and a lower porous water distribution plate 23 are provided, and the area between the upper porous water distribution plate 22 and the lower porous water distribution plate 23 is an adsorbent filling area. The adsorbent filling area comprises an upper microporous plate and a lower microporous plate, the upper microporous plate is positioned at the lower side of the upper porous water distribution plate 22, the lower microporous plate is positioned at the upper side of the lower porous water distribution plate 23, the upper microporous plate 16 and the lower porous water distribution plate An adsorbent is filled betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com