Method for measuring three-dimensional data of autobody and chassis based on optical-electricity encoder

A technology of photoelectric encoder and automobile body, which is applied in the field of three-dimensional data measurement of automobile body and chassis based on photoelectric encoder, which can solve the problems of difficult equipment movement, complicated operation, and low measurement efficiency, and achieve convenient and efficient measurement, accurate measurement, and The effect of flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

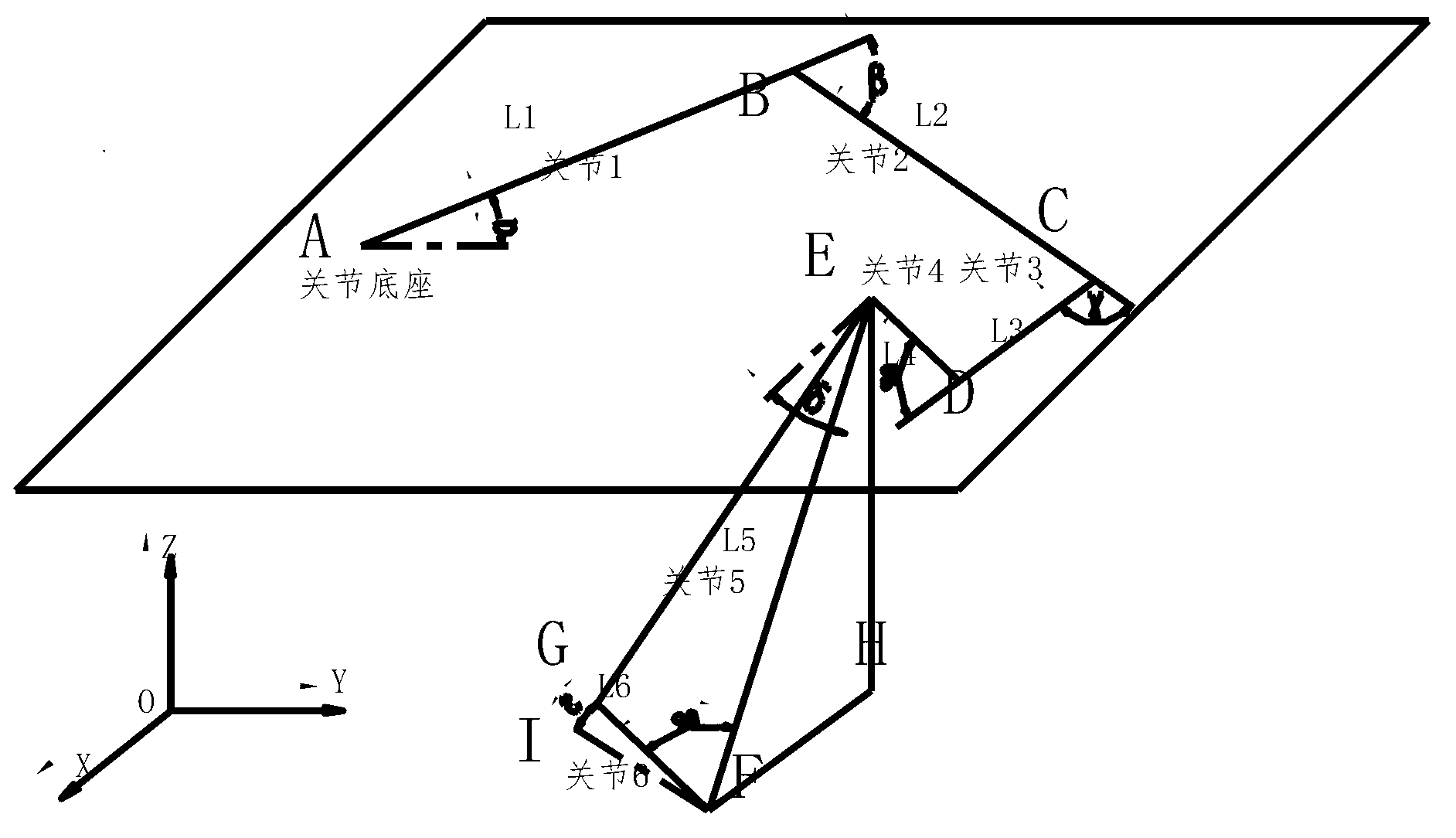

[0020] Refer to the schematic diagram of the present invention figure 1 , The articulated measuring arm is composed of 6 joints, the AB segment is joint 1, the BC segment is joint 2, the CD segment is joint 3, the DE segment is joint 4, the EF segment is joint 5, and the FG segment is joint 6. The measuring arm is fixed on the movable cabinet through the seat, and the base is fixed at point A. The rotation point of joint 1 is A, the rotation point of joint 2 is B, the rotation point of joint 3 is C, the rotation point of joint 4 is D, the rotation point of joint 5 is E, and the rotation point of joint 6 is F; Photoelectric encoders are respectively embedded at the rotation points A, B, C, E, and F.

[0021] Joint 1, joint 2, joint 3, and joint 4 rotate in the ABCD plane, joint 4 is perpendicular to joint 3, joint 5 rotates in the plane EFH perpendicular to joint 4, and joint 6 rotates in the plane GFI perpendicular to joint 5.

[0022] Let the lengths of joints 1 to 6 be L1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com