Electrical connection structure of touch liquid crystal display device

A technology of liquid crystal display device and electrical connection structure, which is applied in the direction of conductive adhesive connection, electrical digital data processing, and data processing input/output process, etc. The problem of large peripheral size of the touch screen, etc., achieves the effect of reducing the overall size, improving the conductivity, and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

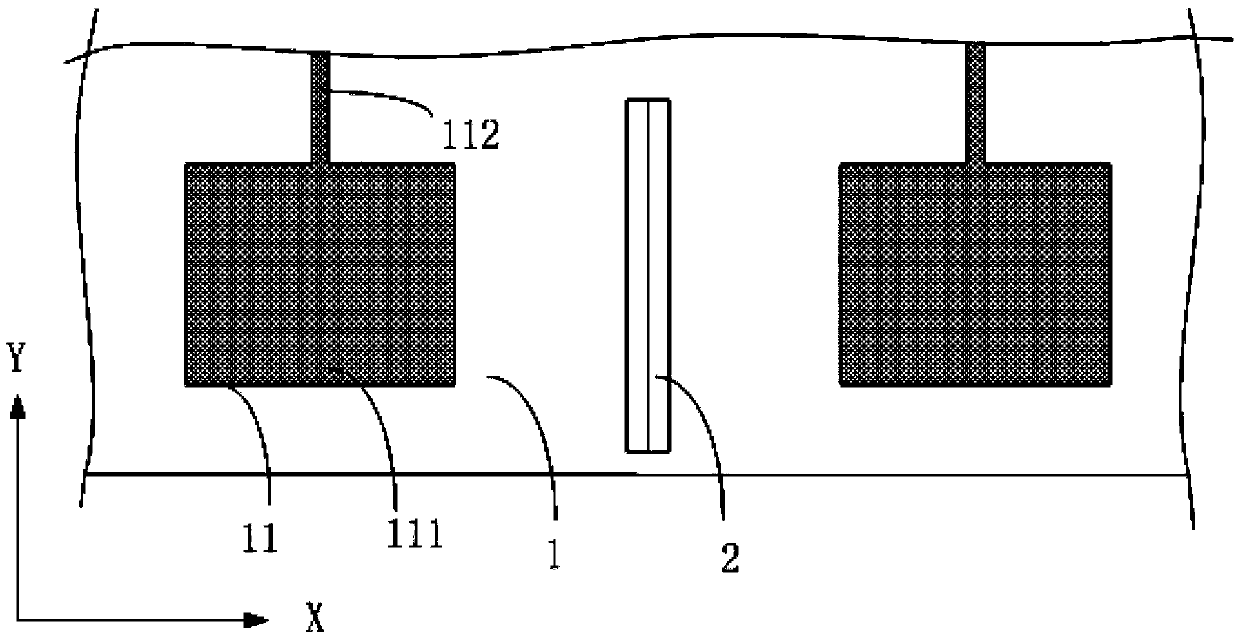

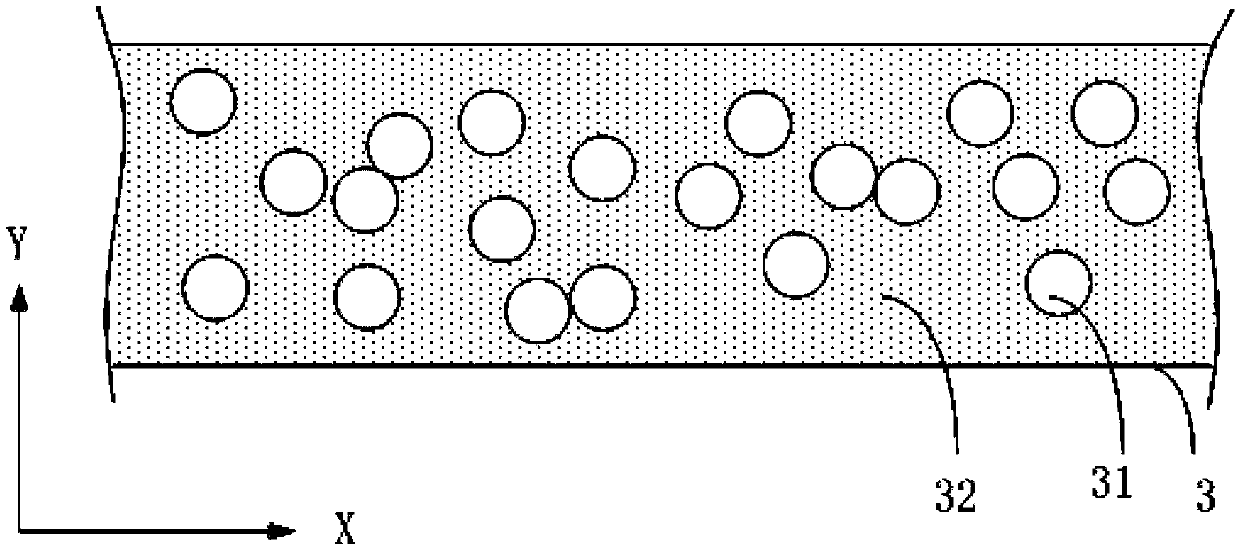

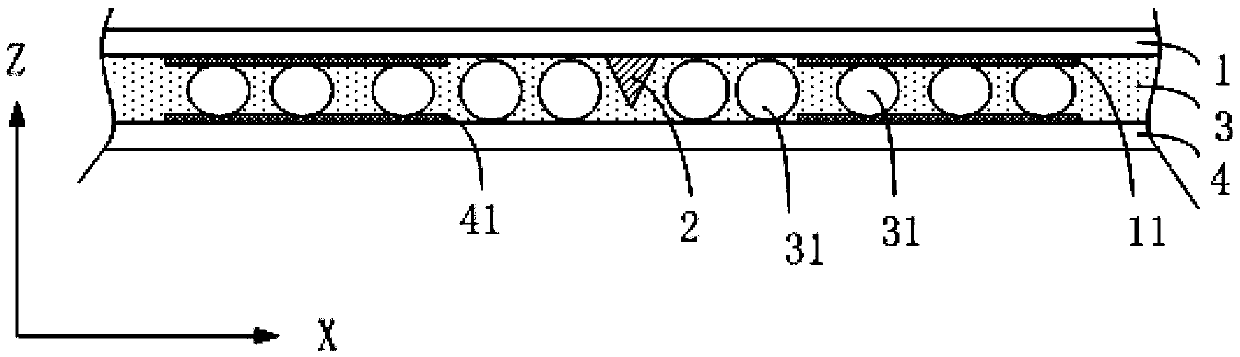

[0038] As mentioned in the background art, in the scheme of electrically connecting the conductive pads on the liquid crystal panel to the integrated circuit through conductive glue, usually to prevent short circuit and mutual interference between adjacent conductive pads, the area of the conductive pads and the distance between two adjacent conductive pads The distance between them is relatively large, which will lead to a large peripheral size of the embedded capacitive touch screen, which will affect the overall size of the touch display device. Moreover, the large area of the conductive pads and the large distance between two adjacent conductive pads will also lead to a large distribution area of the conductive pads, which will increase the required conductive glue and thus increase the cost. Therefore, the present invention discloses an electrical connection structure of a touch-control liquid crystal display device to solve the above problems.

[0039] Please refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com