Large-area material mixing and agitating system

A kind of mixing and stirring, large-area technology, which is applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of harsh working environment, low production efficiency, and high labor intensity of workers, and achieve convenient operation and control. Save manpower and material resources, the effect of compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be described in further detail below, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Various modifications, substitutions and alterations made by means are included within the scope of the present invention.

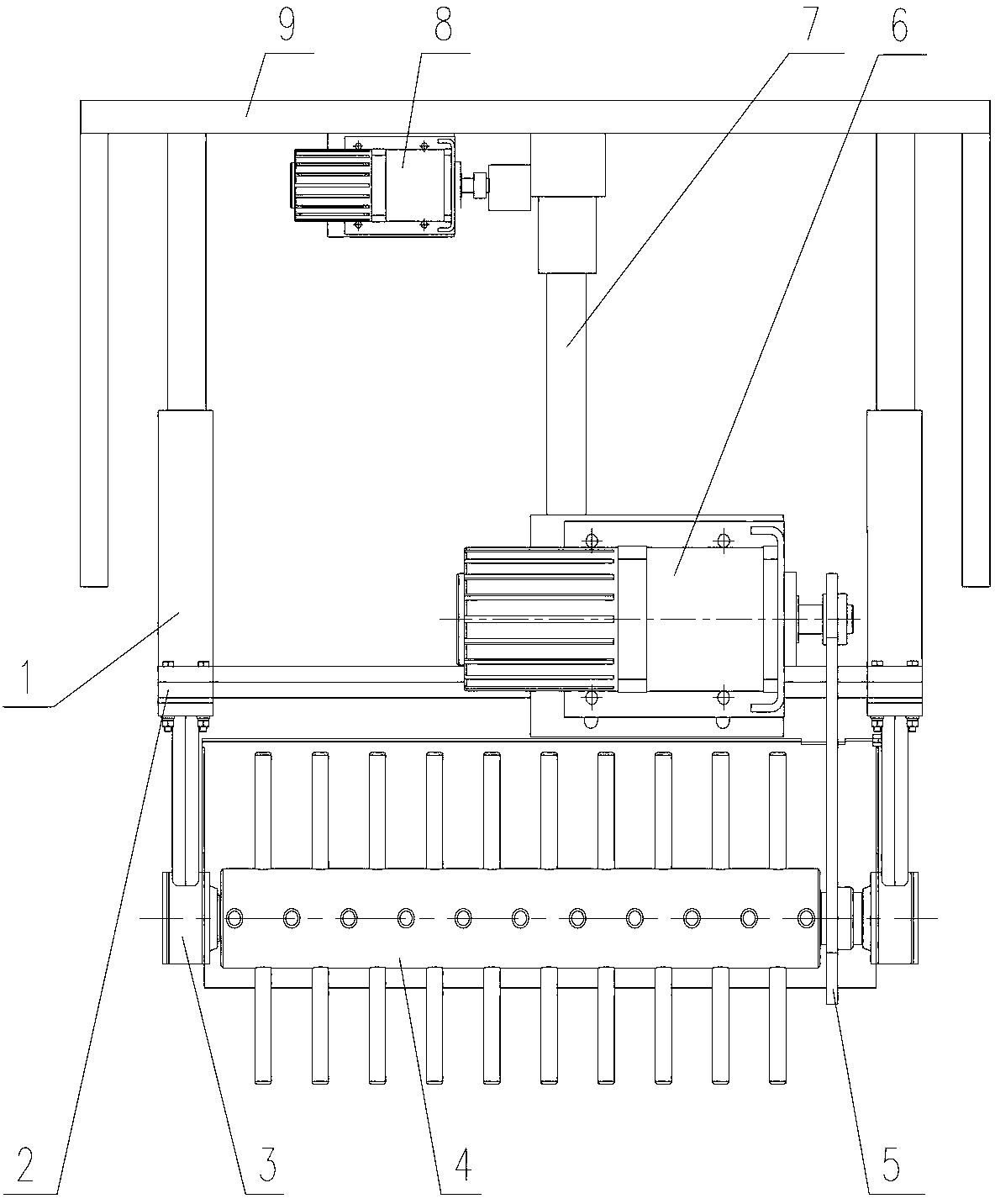

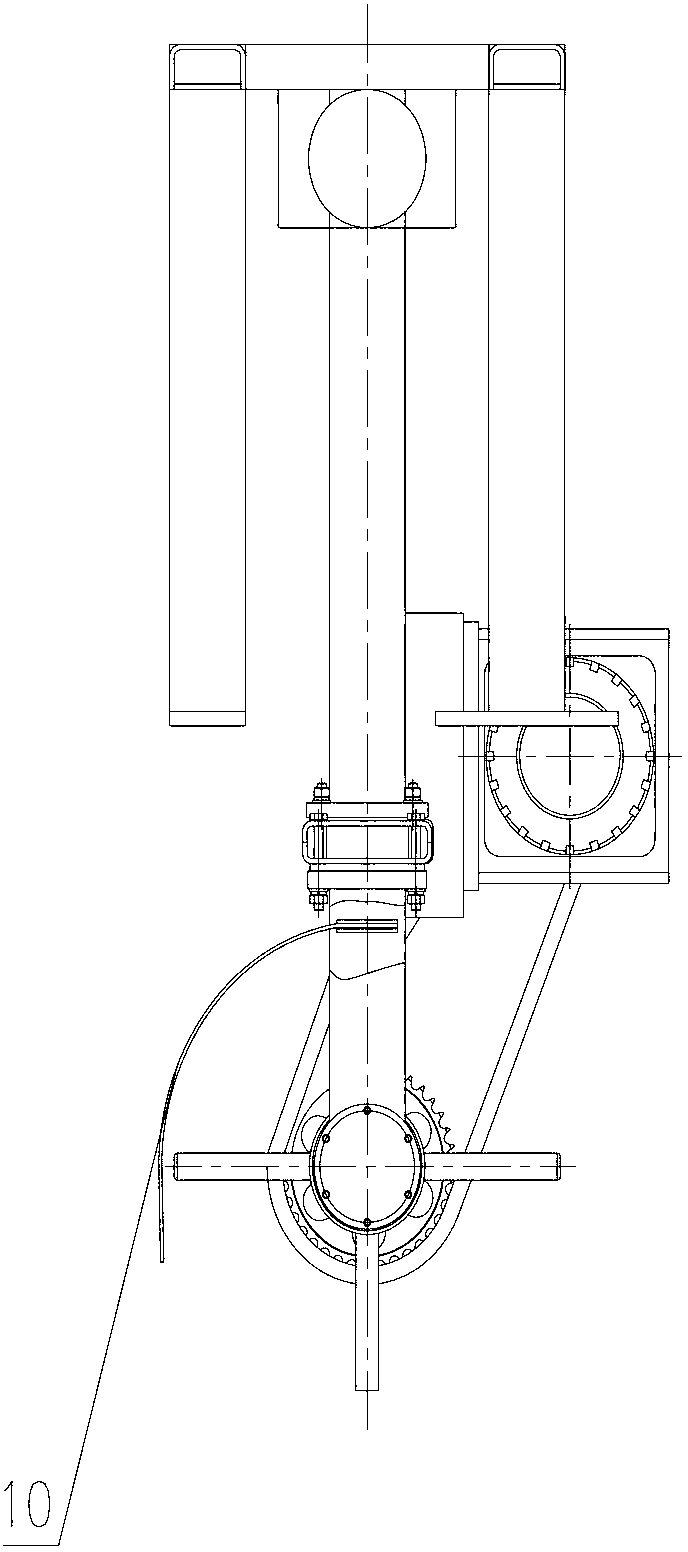

[0014] Such as figure 1 and figure 2 As shown, a large-area mixing and stirring system for materials according to the present invention includes a mounting frame 9, a lifting guide cylinder 1 installed below the mounting frame 9, a lifting device 7 and a small motor 8, and a mounting seat 2. By installing The installation arm 3 connected to the lifting guide cylinder 1 by the seat 2, the sweeping mixing roller 4 installed in the assembly hole of the installation arm 3, the large motor connected to the lifting device 7 installed on the installation seat 2 6. The transmission mechanism 5 connecting the sweeping mixing roller 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com