Smoke conveying device and method for injecting oxygen-enriched gas into flue

An oxygen-enriched gas and delivery device technology, which is applied in the direction of non-flammable liquid/gas delivery, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problem of unsafe and unstable dynamic pressure system, oxygen-enriched gas and flue gas in the flue Mix unevenly and other problems, to achieve the effect of stable mixing uniformity and enhanced mixing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

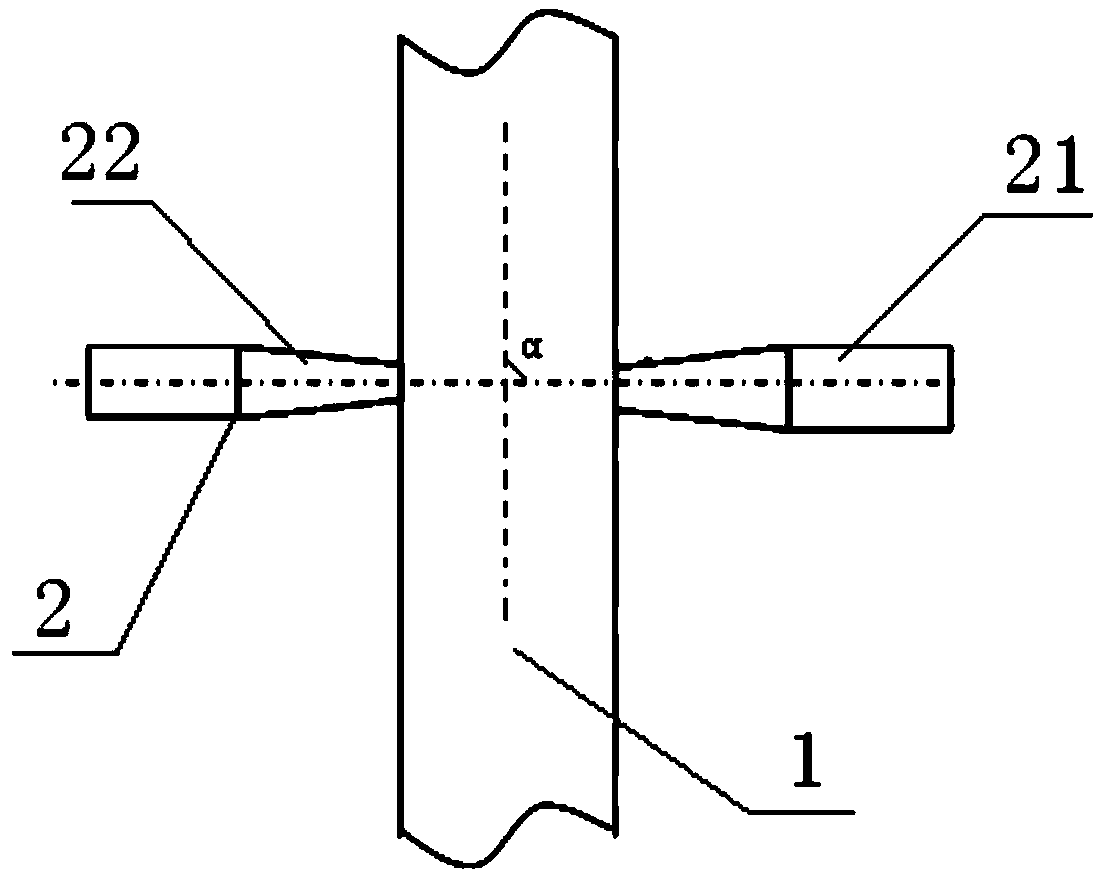

[0033] Such as figure 1 As shown, the flue gas conveying device is symmetrically provided with two oxygen injectors 2 on the side of the cylindrical flue 1, and the oxygen injector 2 includes a straight cylinder part 21 and a tapered part 22, and the tapered part 22 One end is connected to the flue 1 through a flange, and the other end is connected to the straight part 21 through welding, and the flow direction of the flue gas delivered through the flue 1 and the flow direction of the oxygen-enriched gas injected by the oxygen injector 2 are connected. The included angle α is equal to 90°, wherein the tapered portion 22 is a straight-flow circular tube, and the diameter ratio of the two ends of the tapered portion 22 is 2:1.

[0034] The oxygen-enriched gas with an oxygen content of 97% is injected into the flue at a flow rate of 35m / s through the above-mentioned device, and quickly mixed with the flue gas with a flow rate of 15m / s, and then sent into the boiler to participate...

Embodiment 2

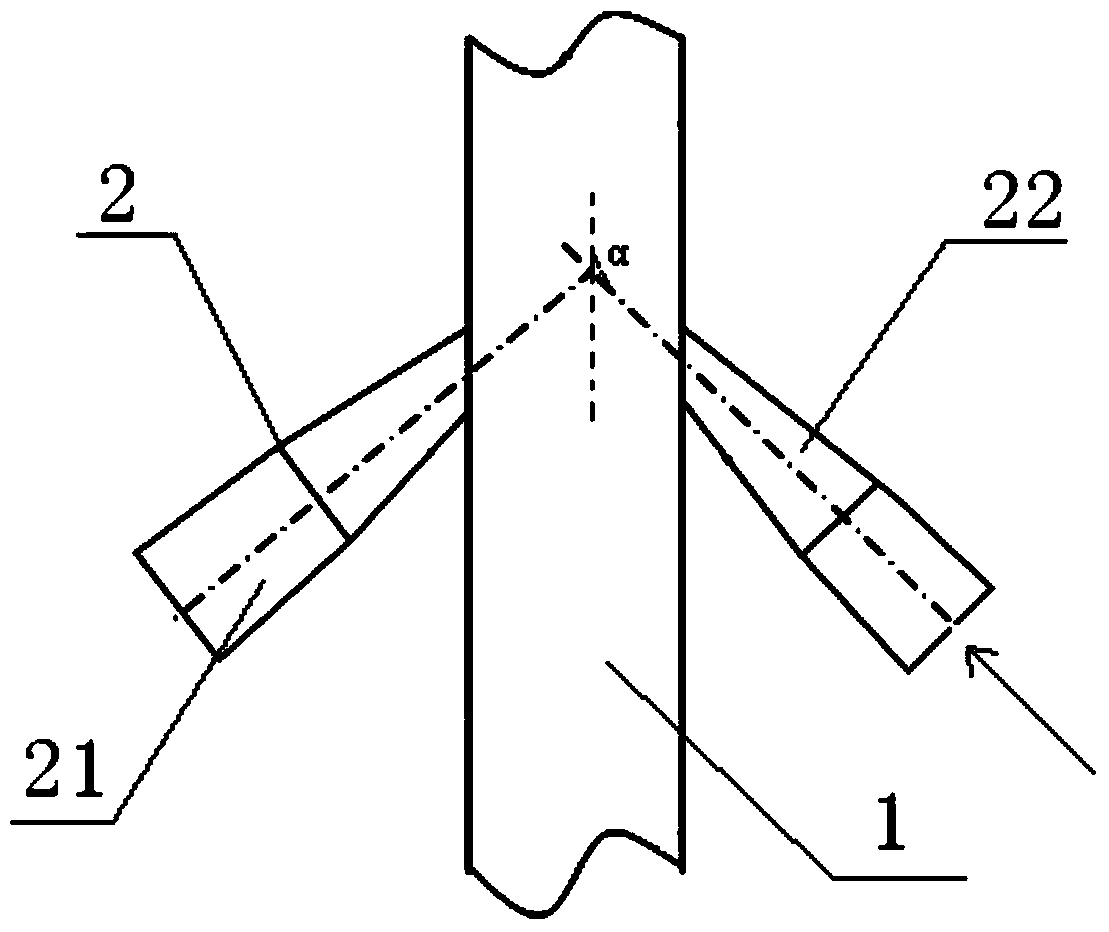

[0036] Such as figure 2 As shown, the flue gas conveying device is symmetrically provided with two oxygen injectors 2 on the side of the cylindrical flue 1, and the oxygen injector 2 includes a straight cylinder part 21 and a tapered part 22, and the tapered part 22 One end is connected to the flue 1 through a flange, and the other end is connected to the straight part 21 through welding, and the flow direction of the flue gas delivered through the flue 1 and the flow direction of the oxygen-enriched gas injected by the oxygen injector 2 are connected. The included angle α is equal to 120°, wherein the tapered part 22 is a swirl tube, and the diameter ratio of the two ends of the tapered part 22 is 1.5:1.

[0037] The oxygen-enriched gas with an oxygen content of 96% is injected into the flue at a flow rate of 25m / s through the above-mentioned device, and quickly mixed evenly with the flue gas with a flow rate of 13m / s, and then sent into the boiler to participate in combusti...

Embodiment 3

[0039]The flue gas conveying device is that four oxygen injectors 2 are arranged symmetrically on the side of the rectangular flue 1, and the oxygen injectors 2 include a straight part 21 and a tapered part 22, and one end of the tapered part 22 is connected to the flue gas. The channel 1 is connected by a flange, and the other end is connected to the straight part 21 by welding, and the angle α between the flow direction of the flue gas delivered through the flue 1 and the flow direction of the oxygen-enriched gas injected by the oxygen injector 2 is equal to 135°, wherein, the tapered part 22 is a straight-flow circular tube, and the diameter ratio of the two ends of the tapered part 22 is 1.2:1.

[0040] The oxygen-enriched gas with an oxygen content of 95% is injected into the flue at a flow rate of 5m / s through the above-mentioned device, and quickly mixed evenly with the flue gas with a flow rate of 10m / s, and then sent into the boiler to participate in combustion, accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com