Mixer of serum materials

A material mixing and mixer technology, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of large difference in material composition between two streams, uneven material mixing, and large equipment damage, etc., and achieve structural Simple, reasonable structure, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

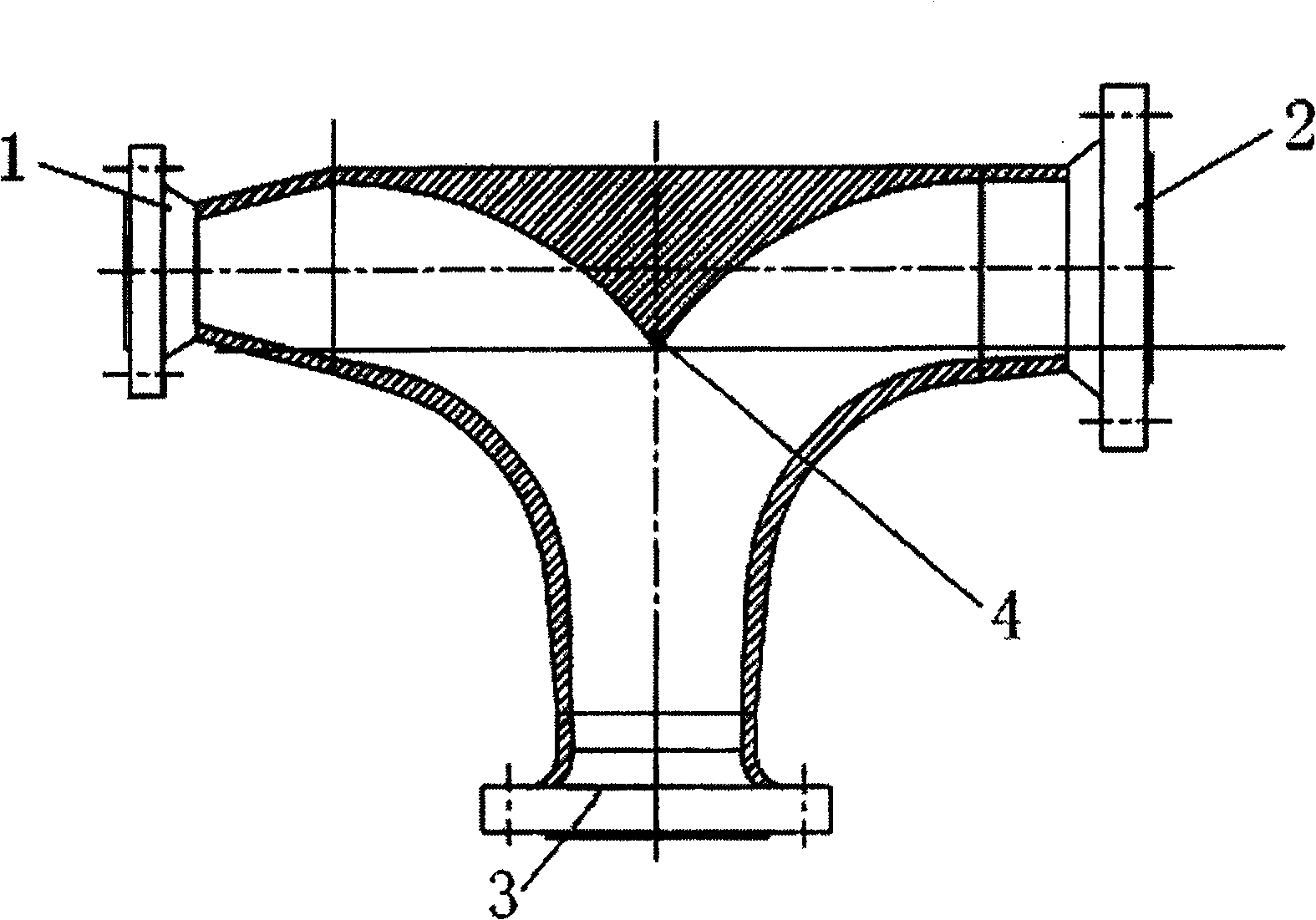

[0009] A kind of slurry material mixer, the basic structure of the mixer is a "D"-shaped three-way steel part, and the three ends of the three-way pipe of the mixer are all connected with flanges, and the mixer's The two straight-through pipes facing each other are placed horizontally, which are respectively the feed pipes of the slurry flow 1 and the feed liquid flow 2; the vertical pipes are the discharge pipe 3 after the mixing of the feed-liquid flow and the slurry flow of the mixer ; It is characterized in that a material flow guide cone 4 is provided in the mixer, and the bottom of the guide cone is centered on the upper pipe wall of the two straight-through material slurry flows and material liquid flow feed pipes, and the guide cone The conical surface of the conical surface of the feed pipe mouth is an arc tangent to the upper pipe surface of the feed pipe; the arc of the arc is the same as the arc of the intersection of the horizontal feed pipe and the mixing discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com