Magnetic roll for wet permanent magnetic roller type strong magnetic separator and assembling process of strong magnetic separator

An assembly process, a drum-type technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as unfavorable weak magnetic mineral tailings sorting, non-metallic iron removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

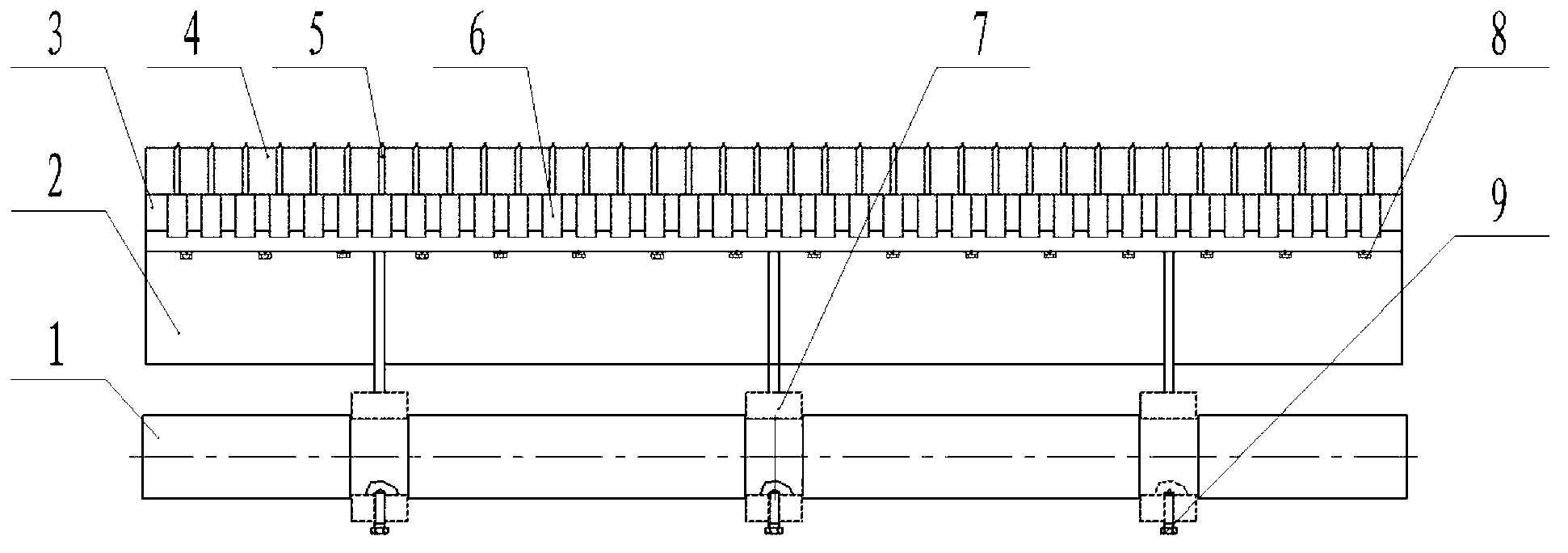

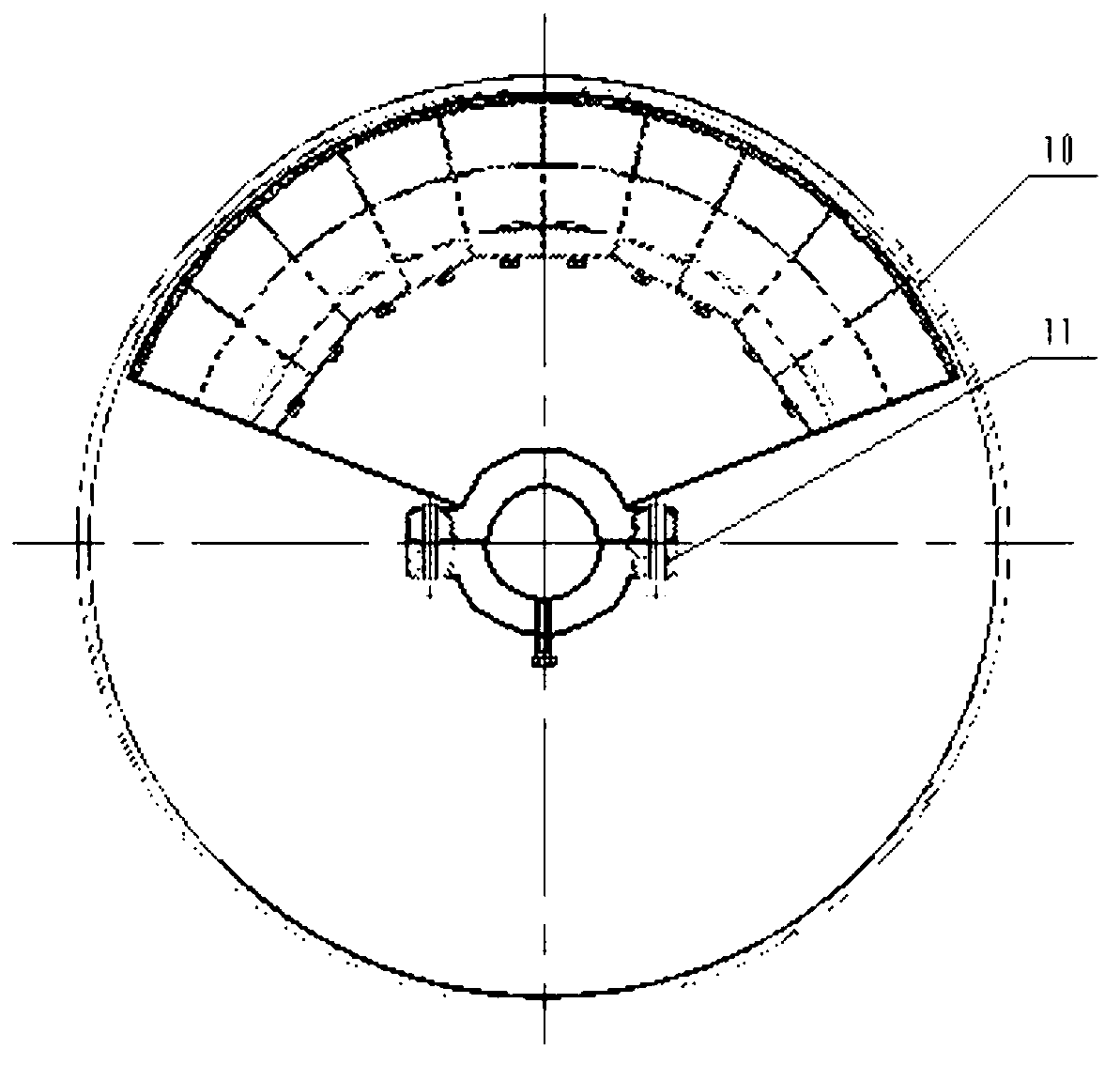

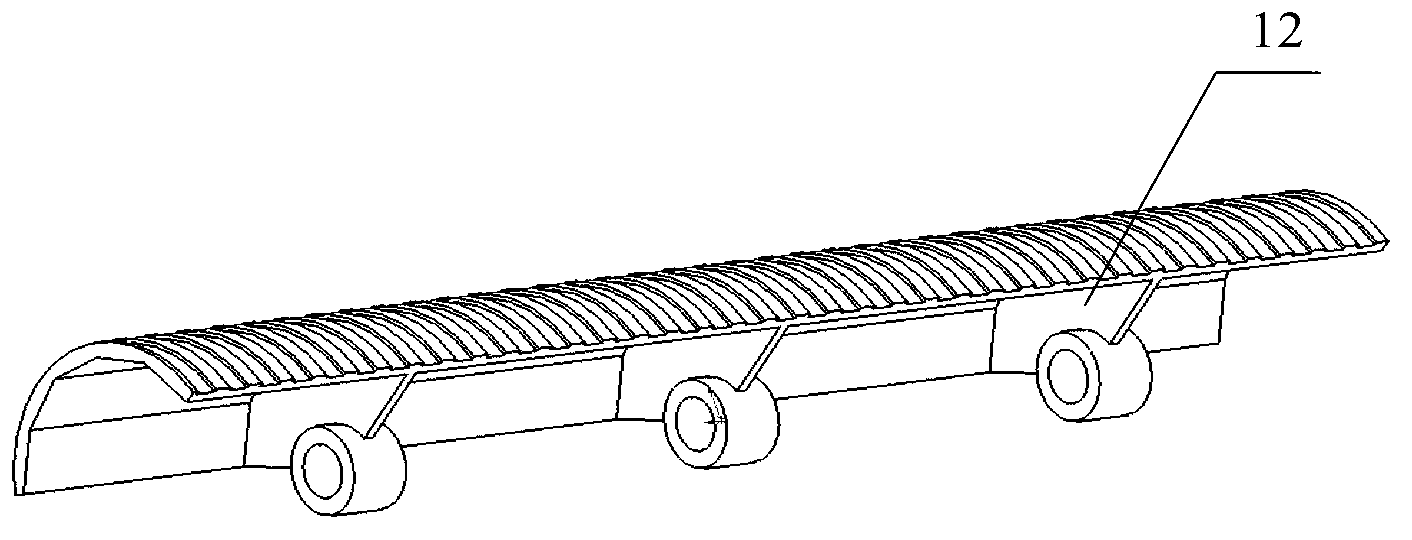

[0028] A magnetic roller for wet permanent magnet drum type strong magnetic separator and its assembly process. The complete set includes a central shaft 1, a magnetic yoke 2, a filling glue 3, a main magnetic block 4, a magnetic pole plate 5, an auxiliary magnetic block 6, Shaft seat 7, auxiliary magnetic block fastening screw 8, shaft seat fastening screw 9, roller 10, lower shaft seat 11, yoke welding assembly 12, fan-shaped auxiliary magnetic block bonding assembly I13, fan-shaped auxiliary magnetic block bonding assembly II14 , Fan-shaped main magnetic block bonding assembly Ⅰ15, sector-shaped main magnetic block bonding assembly Ⅱ16, nut coupling 17, end cover Ⅰ18, transmission sleeve 19, bearing seat 20, doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com