Full-automatic device for picking and placing rechargeable battery in transfer case

A technology for rechargeable batteries and pick-and-place devices, applied in the direction of electric power devices, power devices, circuits or fluid pipelines, etc., can solve problems such as low efficiency, high labor intensity, time-consuming and labor-intensive, etc., to improve efficiency, reduce labor intensity, Easy to charge and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

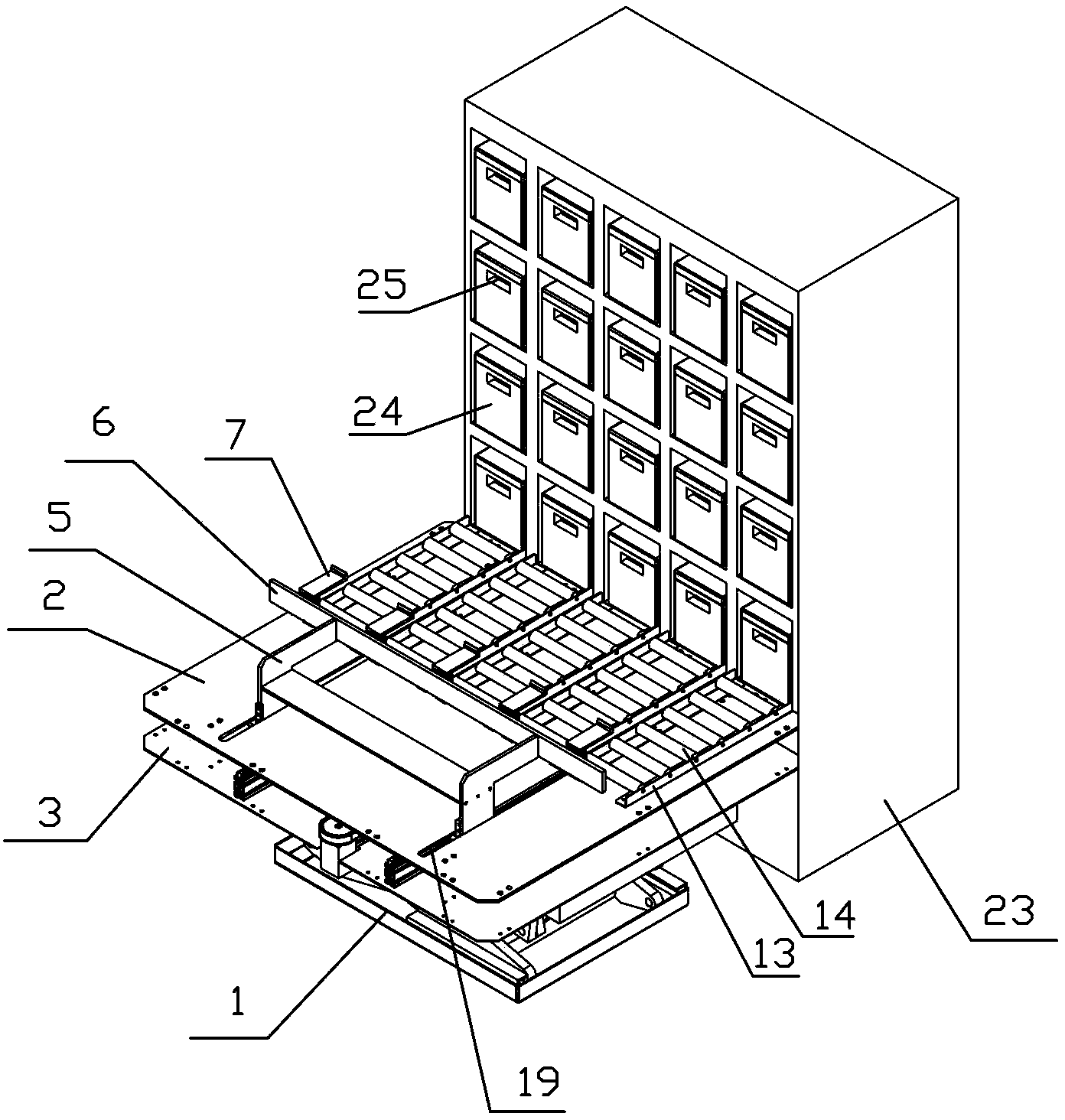

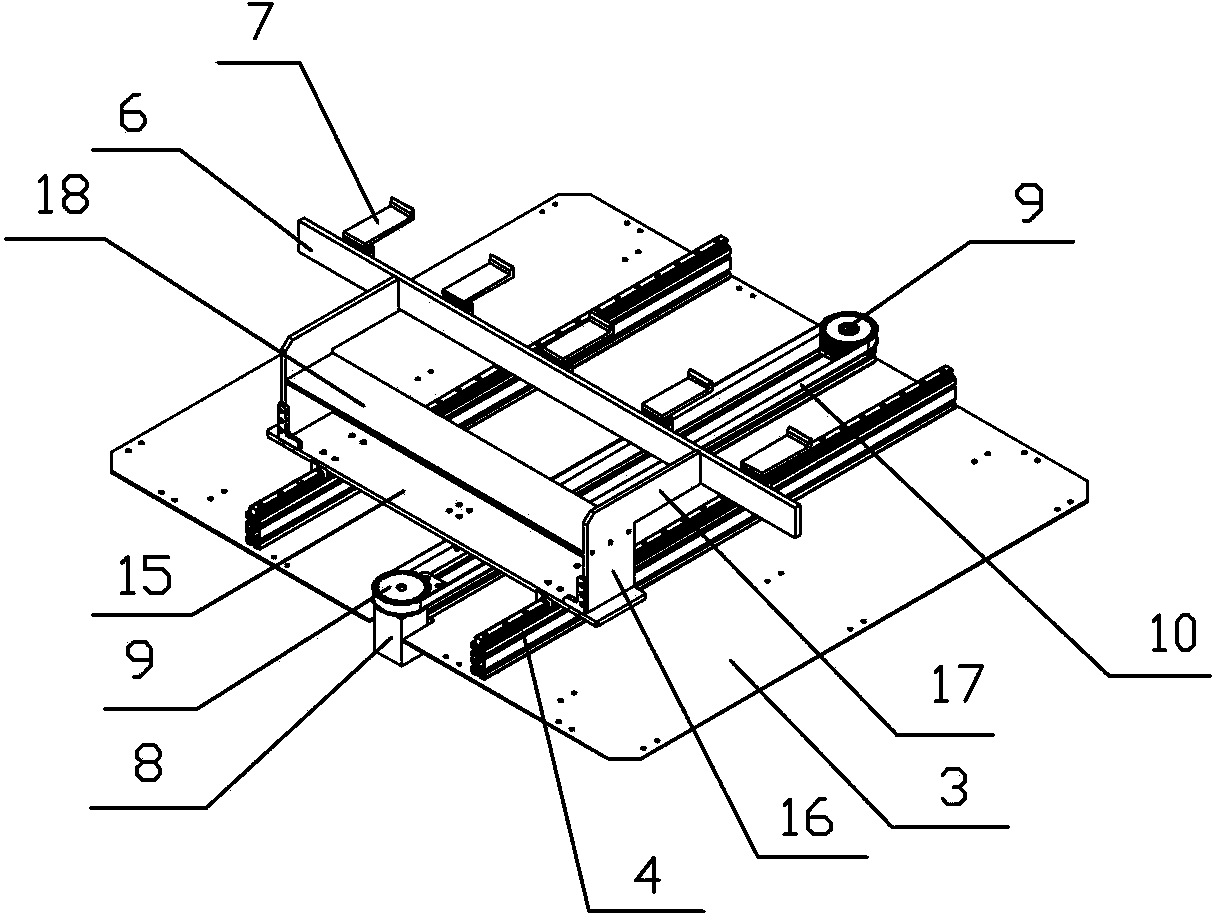

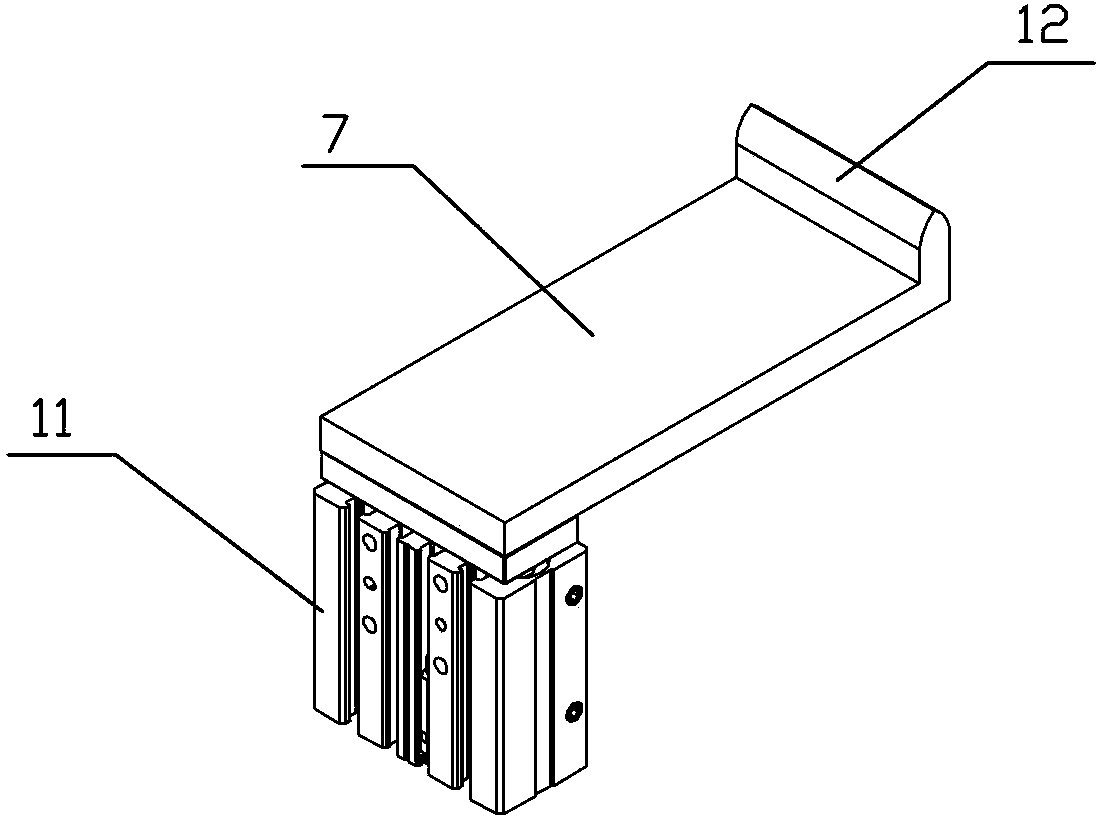

[0022] Example: The fully automatic pick and place device for rechargeable batteries in the transfer box of this example, such as figure 1 As shown, it includes a lifting mechanism 1, a battery pick-and-place mechanism installed on the lift mechanism 1, and a buffer platform 2 mounted on the battery pick-and-place mechanism. like Figure 4 As shown, the lifting mechanism 1 includes a base 20, a hydraulic cylinder 21 and four crossed telescopic frames 22. The base 20 is placed on the ground, the hydraulic cylinder 21 is installed at the center of the base 20, and the piston of the hydraulic cylinder 21 and the battery are picked and placed. The bottom plate 3 on the mechanism is connected, and telescopic frame groups are symmetrically installed between the left and right sides of the base 20 and the bottom plate 3 of the battery pick-and-place mechanism. like figure 2As shown, the battery pick-and-place mechanism includes a base plate 3 and two linear guide rails 4 mounted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com