Railway fastener self-adaptive positioning method based on image sequence and high-speed detection system

An image sequence and railway fastener technology, which is applied to railway car body parts, railway vehicle shape measuring devices, railway auxiliary equipment, etc., can solve problems such as automatic positioning of railway fasteners, to ensure integrity, reduce heat, and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

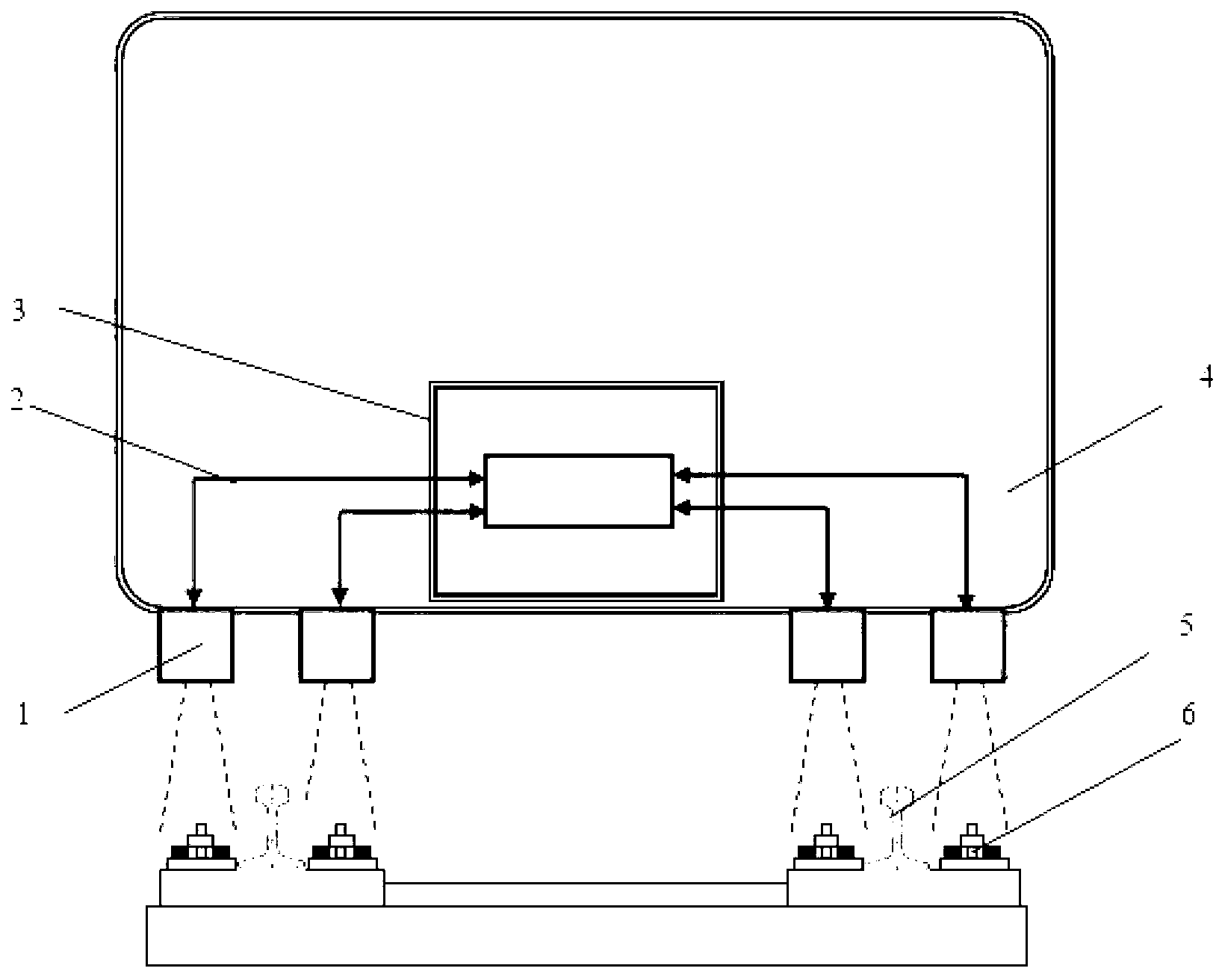

[0034] figure 1 It is a schematic diagram of the composition principle of the high-speed detection system for railway fasteners according to an embodiment of the present invention. The detection system of the present invention consists of three parts: a detector 1 , a cable 2 and a controller 3 . There are 4 detectors 1 in total, all of which are installed under the train carriage 4, facing directly above the area where the fasteners 6 on both sides of the two rails 5 are located. The controller 3 is installed in the compartment 4 and connected with the four detectors 1 through cables 2 . During the running of the train, the detector 1 works continuously and acquires the image of the area where the fastener 6 is located in real time, and transmits it to the controller 3 through the cable 2, and automatically judges and realizes the automatic positioning of the fastener 6 through image processing and pattern recognition.

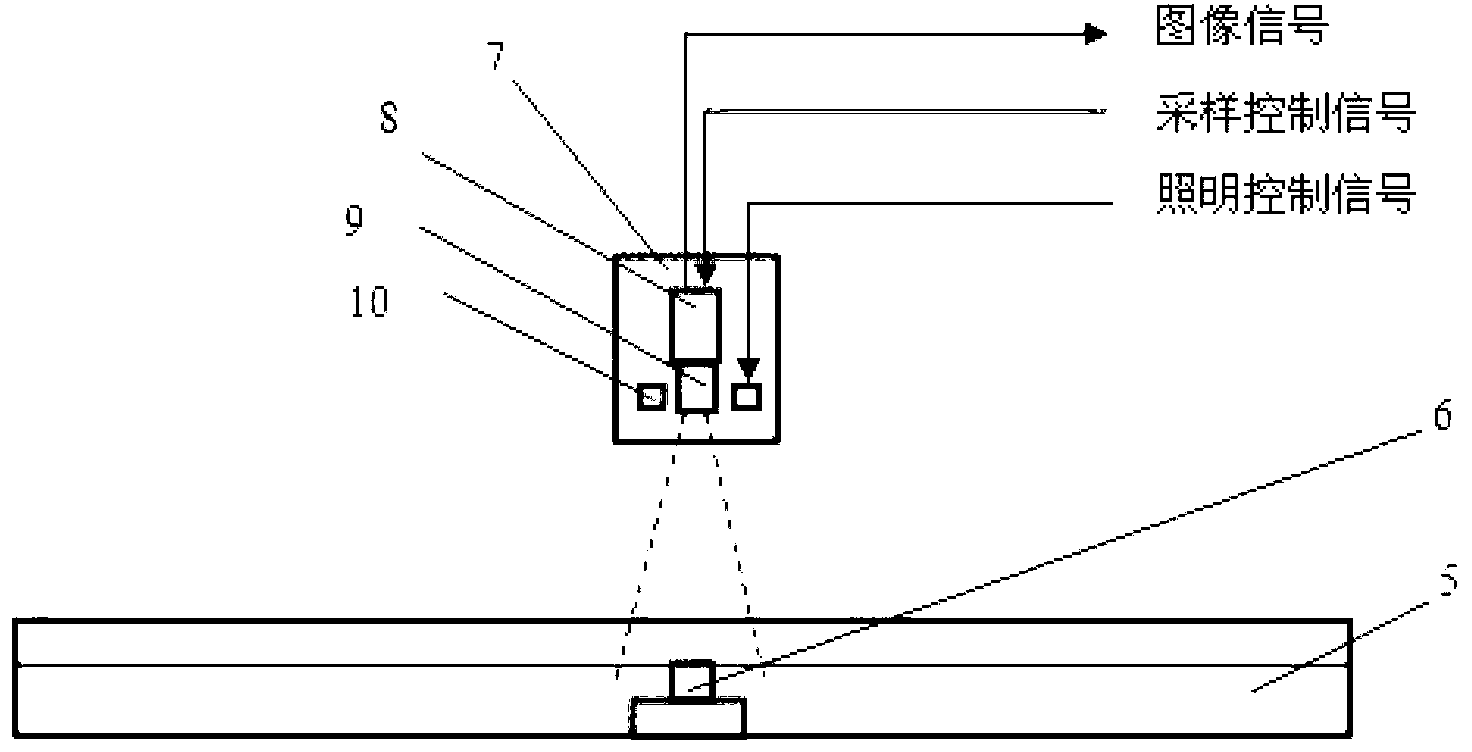

[0035] figure 2 It is a schematic diagram of the co...

Embodiment 2

[0044] This embodiment relates to the method for adaptive positioning of railway fasteners carried out by the system of Embodiment 1. The method includes the following steps:

[0045] (1) After the stabilized power supply of the controller 3 is turned on, the computer 11 in the controller 3 and the camera 8 in the detector 1 start to power on and work.

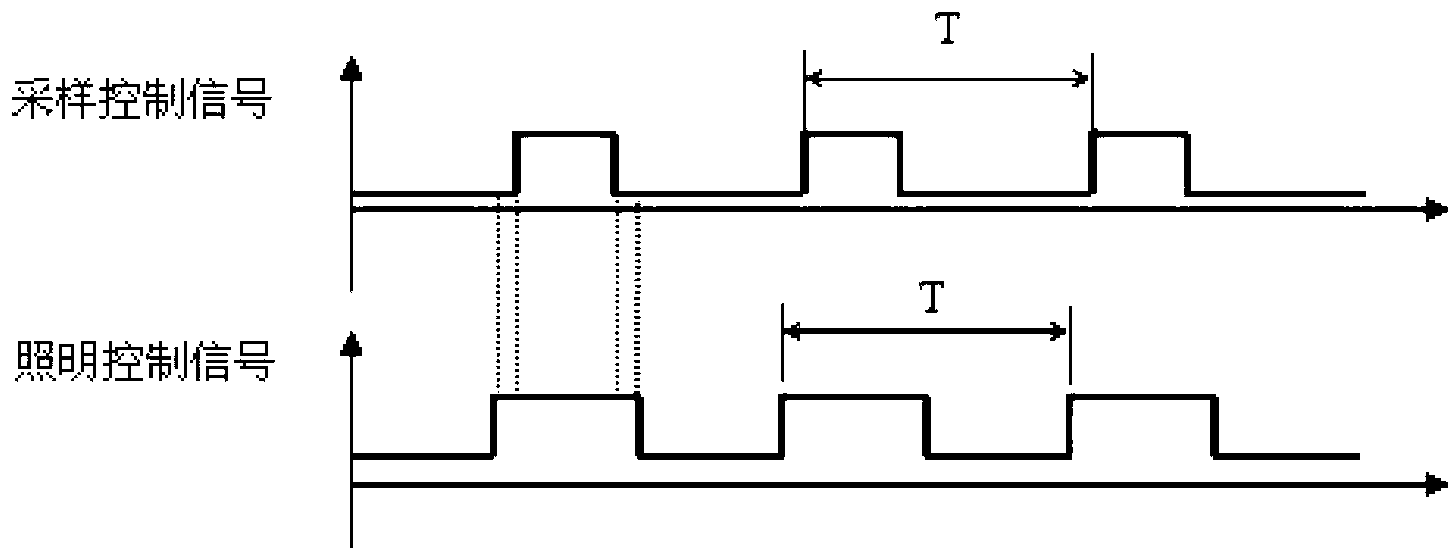

[0046] (2) The computer 11 in the controller 3 sends a sampling control signal and a lighting control signal to the camera 8 and the light source 10 in the detector 3 respectively at a relatively high fixed frequency, and the sampling frequency is generally the maximum value of the occurrence frequency of fasteners More than 2 times. For example, if the running speed of the train is 400km / h, the distance between the sleepers is 0.6m, and the maximum occurrence frequency of the corresponding fasteners is about 185Hz, then the sampling frequency is preferably 400Hz. The lighting control signal arrives earlier than the sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com