Method for preparing polymeric microsphere in alcohol-water mixed solvent

A technology of mixing solvents and polymers, which is applied in the field of polymer materials and analysis, can solve the problems of specificity decline, achieve the effects of easy operation, mild reaction conditions, and enhanced specific adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

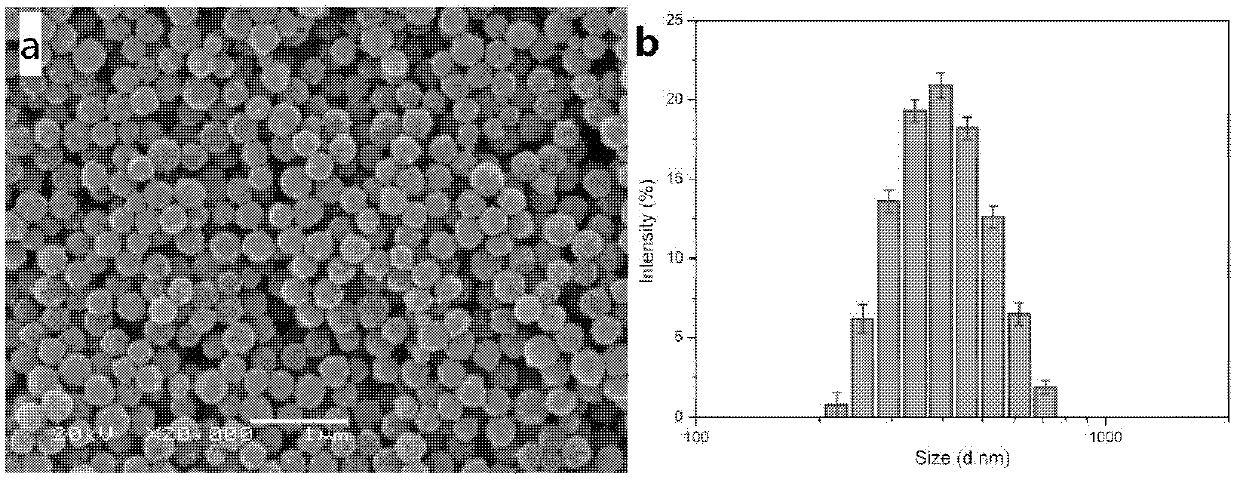

[0025] In a 25mL round bottom flask, install a condenser, add 2ml of ethanol and 8ml of water to form a mixed solution, add 33.8mg of 4-vinylphenylboronic acid, 221.1mg of methylenebisacrylamide and 5mg of azobis Isobutyronitrile was sonicated for 1 minute to dissolve the added reagent to form a homogeneous solution, after which nitrogen gas was passed for 15 minutes, and a magnetic stirrer was added. The reaction device was placed in an oil bath and heated evenly and slowly, and the temperature rose to 70°C within 30 minutes. The magnetic stirring bar was kept at a speed of 300 rad / min. The reaction conditions were maintained for 24 hours, the reaction was stopped, and cooled to room temperature. Use a high-speed centrifuge to centrifuge at a speed of 10,000 rad / min, remove the supernatant, add a mixed solution of ethanol and water to wash three times, and then wash three times with tetrahydrofuran, acetone, and anhydrous ether. Dry for 24 hours to obtain a polymer sample. ...

Embodiment 2

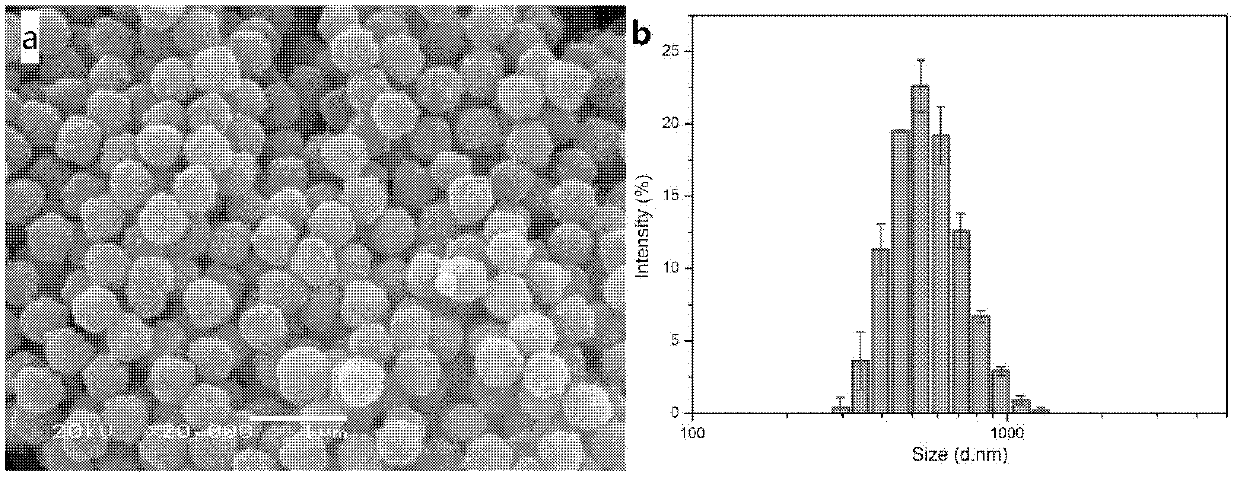

[0027] In a 25mL round bottom flask, install a condenser, add 2ml of ethanol and 8ml of water to form a mixed solution, add 47.35mg of 4-vinylbenzeneboronic acid, 148mg of methylenebisacrylamide, and 45.6μL of divinylbenzene and 5 mg of azobisisobutyronitrile, ultrasonication for 1 min to dissolve the added reagents to form a uniform solution, then pass nitrogen gas for 15 min, and add a magnetic stirrer. The reaction device was placed in an oil bath and heated evenly and slowly, and the temperature rose to 70°C within 30 minutes. The magnetic stirring bar was kept at a speed of 300 rad / min. The reaction conditions were maintained for 24 hours, the reaction was stopped, and cooled to room temperature. Use a high-speed centrifuge to centrifuge at a speed of 10,000 rad / min, remove the supernatant, add a mixed solution of ethanol and water to wash three times, and then wash three times with tetrahydrofuran, acetone, and anhydrous ether. Dry for 24 hours to obtain a polymer samp...

Embodiment 3

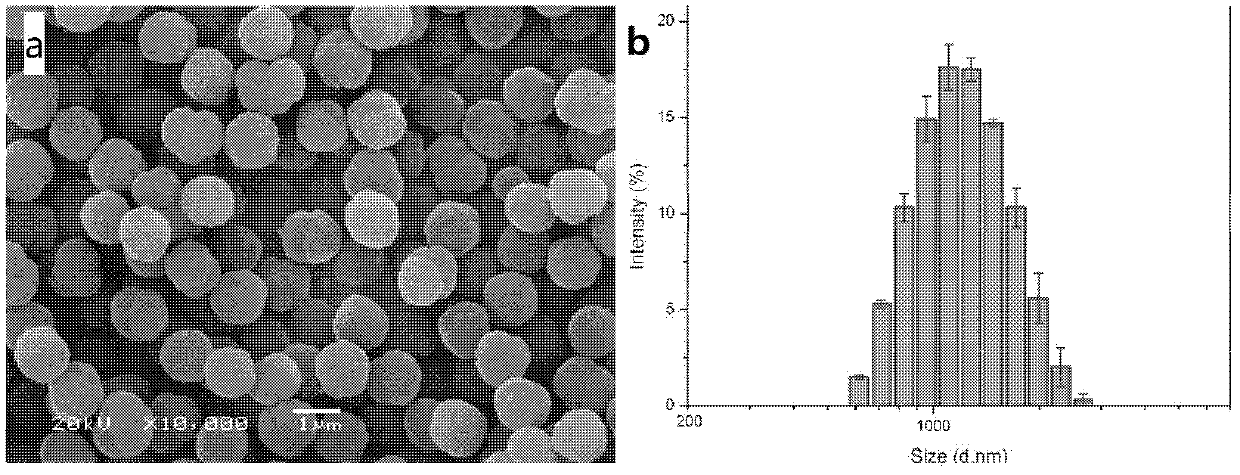

[0029] In a 25mL round bottom flask, install a condenser, add 2ml of ethanol and 8ml of water to form a mixed solution, add 29.6mg of 4-vinylphenylboronic acid, 185mg of methylenebisacrylamide, 17.1μL of methacrylic acid and 5mg azobisisobutyronitrile, sonicated for 1 min to dissolve the added reagent to form a homogeneous solution, then pass nitrogen gas for 15 min, and add a magnetic stirrer. The reaction device was placed in an oil bath and heated evenly and slowly, and the temperature rose to 70°C within 30 minutes. The magnetic stirring bar was kept at a speed of 300 rad / min. The reaction conditions were maintained for 24 hours, the reaction was stopped, and cooled to room temperature. Use a high-speed centrifuge to centrifuge at a speed of 10,000 rad / min, remove the supernatant, add a mixed solution of ethanol and water to wash three times, and then wash three times with tetrahydrofuran, acetone, and anhydrous ether. Dry for 24 hours to obtain a polymer sample. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap