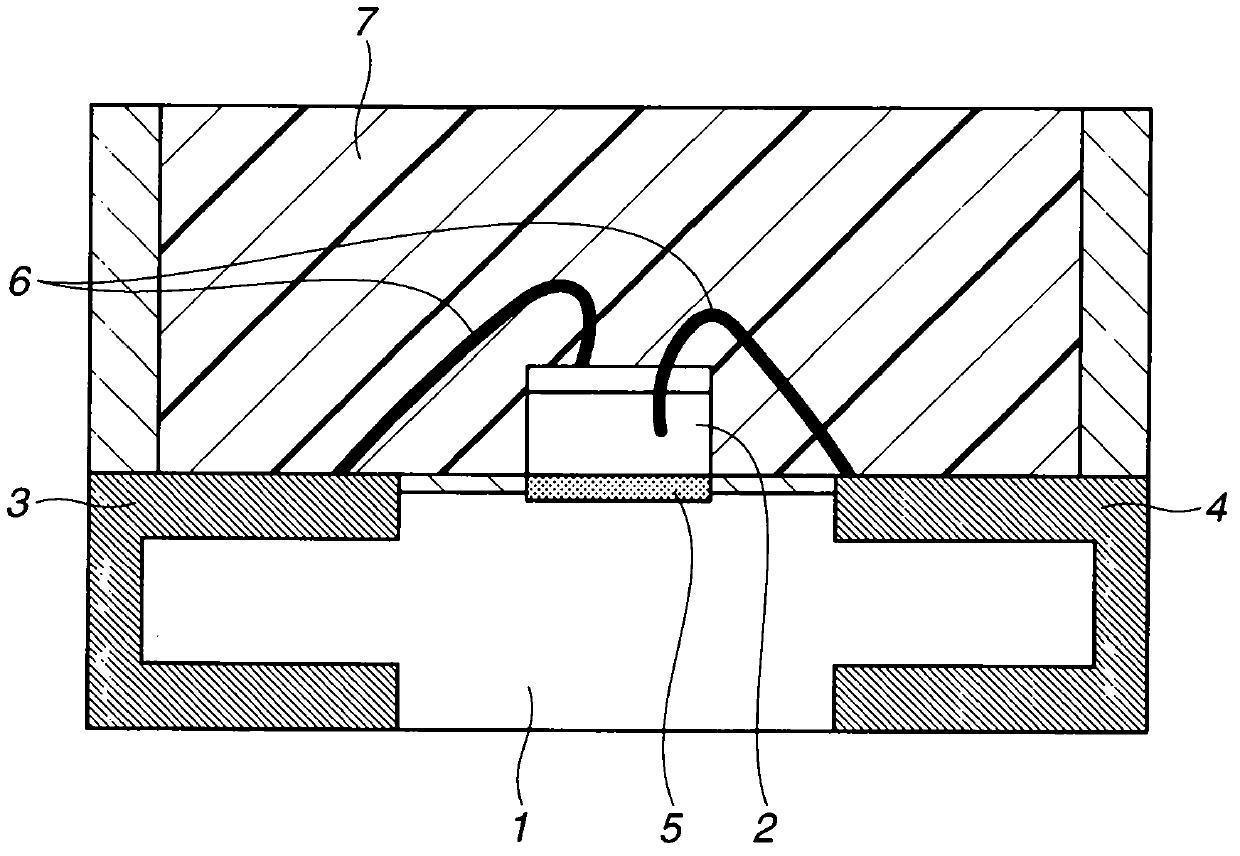

Curable silicone resin composition and optoelectronic device

A technology of resin composition and silicone, which is applied in the direction of electrical solid devices, semiconductor/solid device components, electrical components, etc., can solve problems such as difficulty in preventing silver vulcanization, brightness extraction efficiency and cost impact, and achieve high resistance and difficulty cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

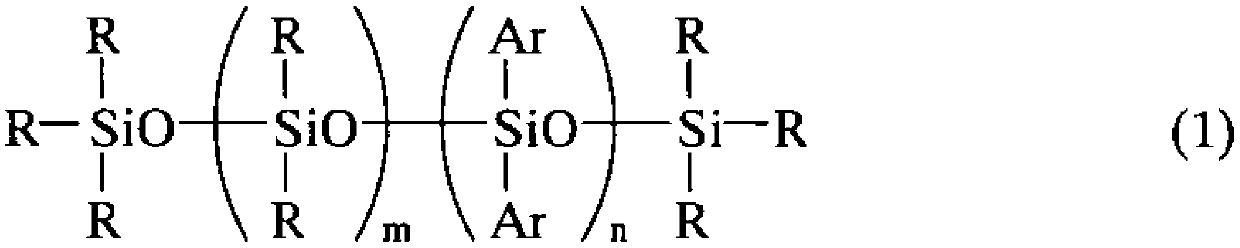

Method used

Image

Examples

Embodiment 1

[0166] Composition (a) was prepared by mixing 100 parts of Subcomposition #1 with 10 parts of composite silicone powder (KMP-600, manufactured by Shin-Etsu Chemical Co., Ltd.) having an average particle diameter of 5 μm until uniform.

Embodiment 2

[0168] Composition (b) was prepared by mixing 100 parts of Subcomposition #1 with 10 parts of silicone resin powder (X-52-1621, manufactured by Shin-Etsu Chemical Co., Ltd.) having an average particle diameter of 5 μm until uniform.

Embodiment 3

[0170] Composition (c) was prepared by mixing 100 parts of Subcomposition #2 with 5 parts of composite silicone powder (X-52-7030, manufactured by Shin-Etsu Chemical Co., Ltd.) having an average particle diameter of 0.8 μm until uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com