Tufted carpet reel device

A tufted carpet and stretcher technology, applied in the field of tufted carpet processing equipment, can solve the problems of low processing efficiency and large space occupation, and achieve the effects of improving processing efficiency, saving space and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

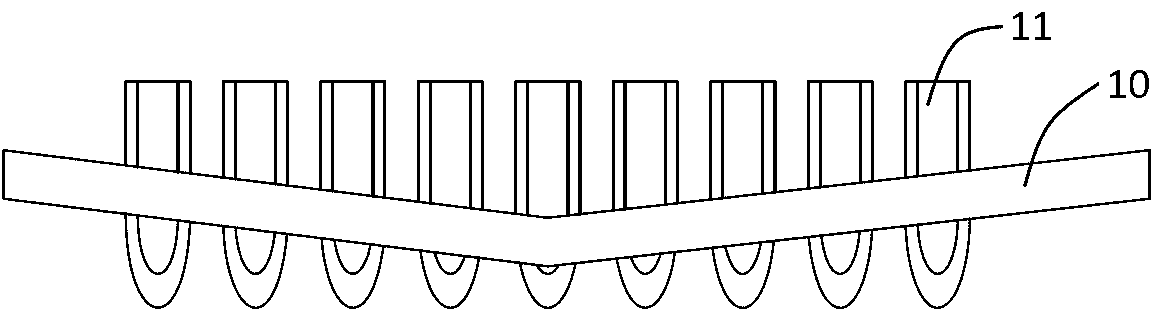

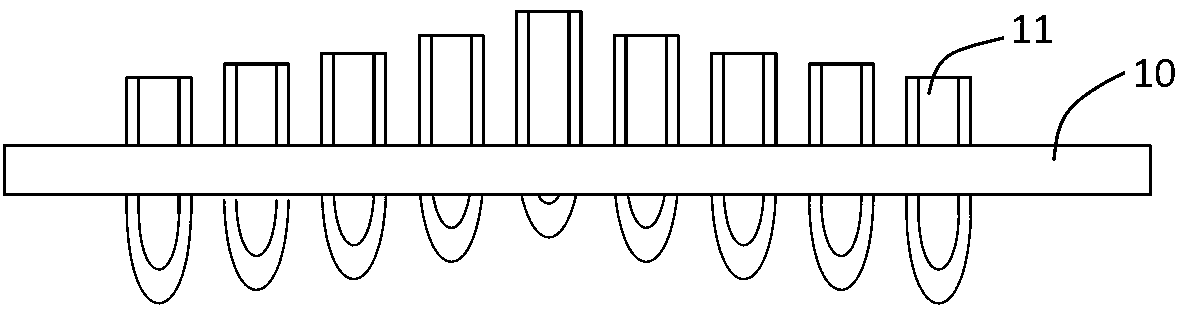

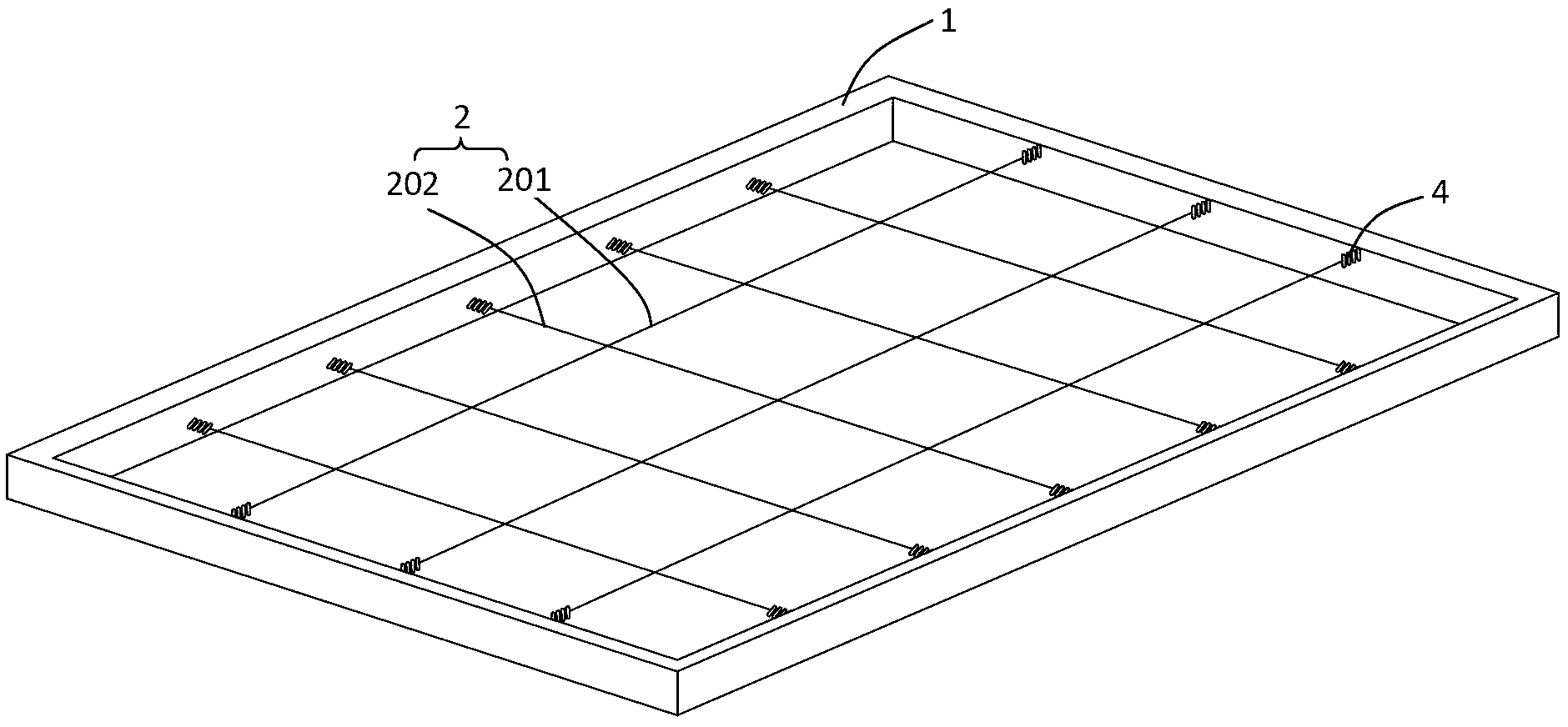

[0027] Such as figure 2 As shown, the base fabric stretcher 1 is provided with several steel wire strips 2, and both ends of each steel wire 2 are connected to the base fabric stretcher 1 through elastic members. During tufting, the base fabric stretcher 1 can effectively support the base fabric and prevent the base fabric from swinging (moving along the tufting direction of the tufting needles 6).

Embodiment 2

[0029] Embodiment 2 is an improvement made on the basis of Embodiment 1, as image 3 , Figure 4 As shown, several slide pipes 3 are connected in series on each steel wire bar 2 . The slide tube 3 can make the tufting needling needles 6 quickly stagger for tufting.

Embodiment 3

[0031] Embodiment 3 is an improvement made on the basis of Embodiment 2, as Figure 5 , Figure 6 As shown, steel balls 5 are arranged between adjacent sliding tubes 3 . The steel ball 5 is provided with a central hole (not shown in the figure), and the diameter of the central hole is slightly larger than the diameter of the steel wire so that the steel wire can pass through. The outer diameter of the steel ball 5 is greater than the outer diameter of the slide tube 3 so that the base cloth can be supported on the steel ball 5, and a gap is formed between the slide tube 3 and the base cloth. When the tufted acupuncture needle head 6 hits the slide tube 3, Since the base is arranged above the slide tube 3, the tufted needling needles 6 are more easily slid away from one side thereof.

[0032] The horizontal setting of the base cloth stretcher 1 can reduce the moving range of the mobile device and save space. At the same time, processing efficiency can also be improved. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com