Prefabricated short slab floating track bed and construction method

A technology for floating ballast bed and short board, applied in the field of ballast bed, can solve the problems of limited carrying capacity of hoisting transportation tools, limited tunnel space, long construction period, etc., achieve convenient and fast transportation and hoisting, improve local bearing capacity, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

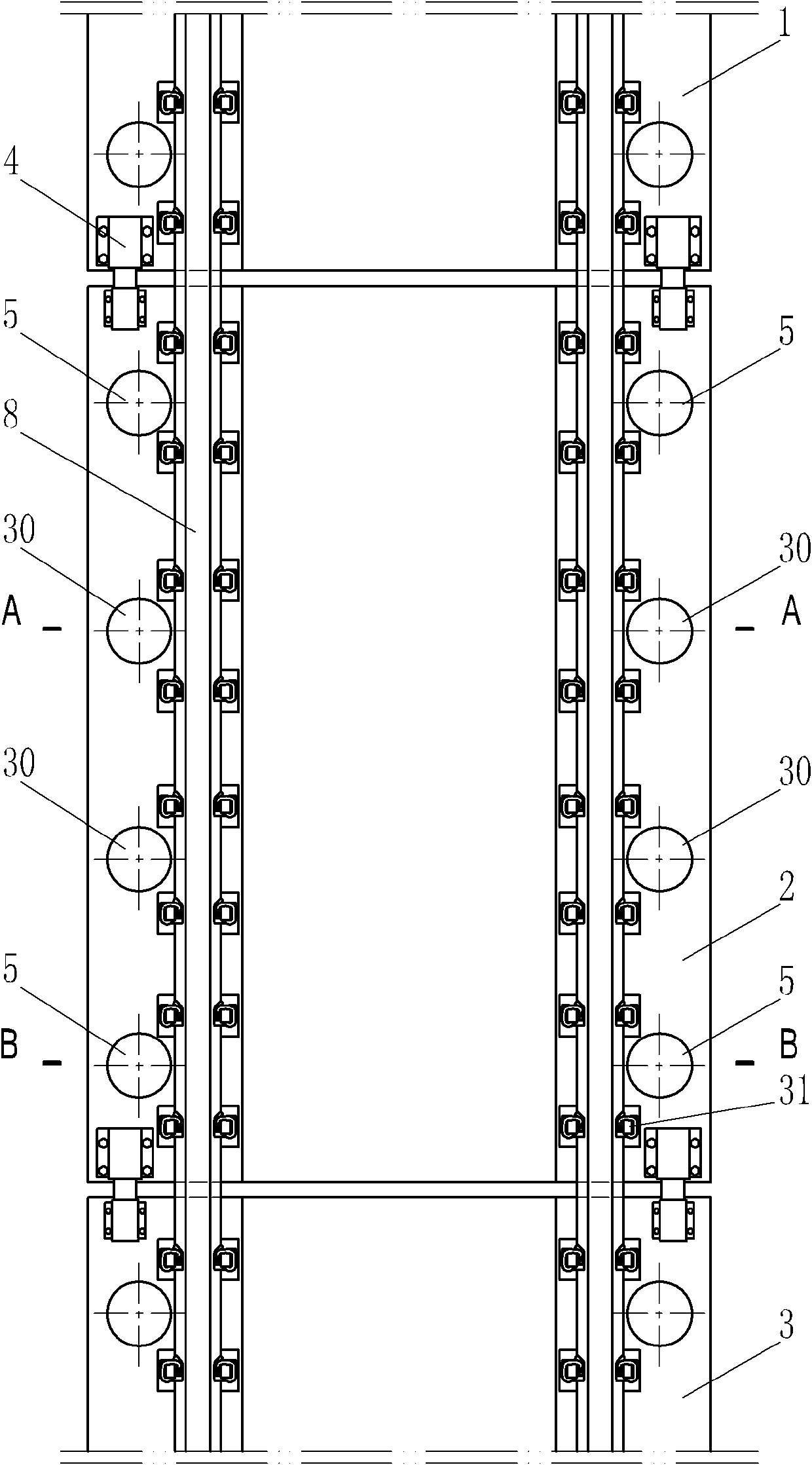

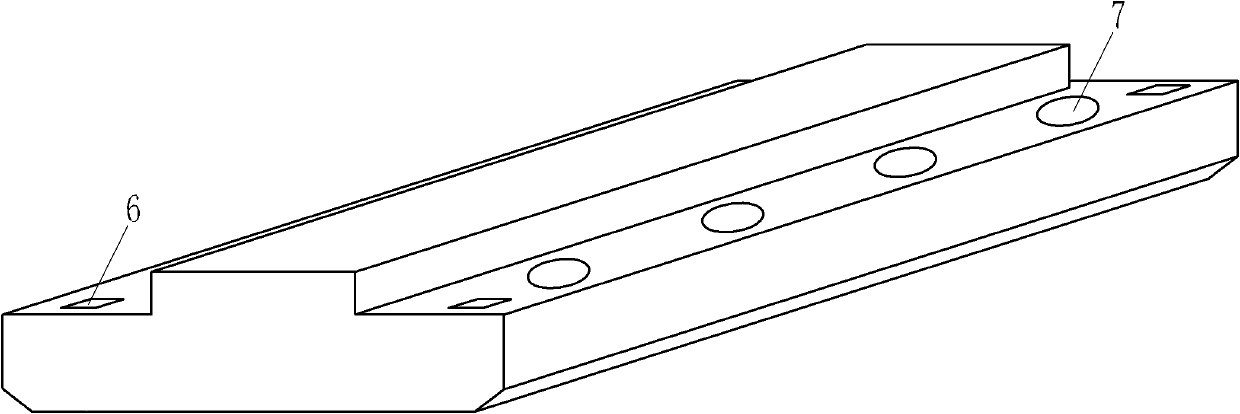

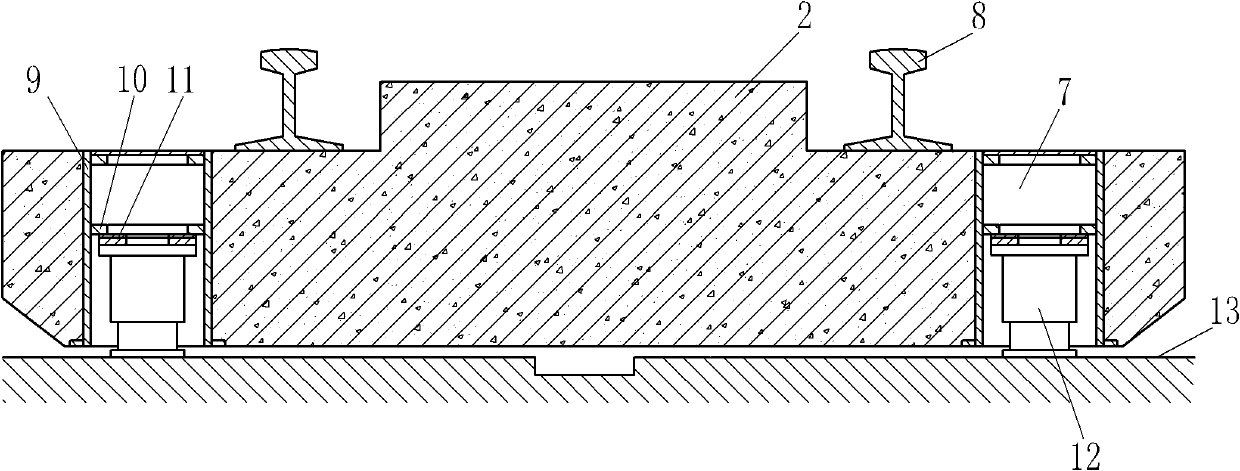

[0029] Such as figure 1 A section of typical structure of the prefabricated short slab floating ballast bed shown in the present invention, to adopt figure 2 The prefabricated short slab of the structure shown is taken as an example of a floating slab. The length of the prefabricated short slab is 8m, and anchors 6 are integrated on the prefabricated short slab. In addition, each prefabricated short slab is also provided with eight reserved through holes. 7. For the convenience of description, the prefabricated short slabs are numbered 1, 2 and 3 in sequence, and the structure of the prefabricated short slab floating ballast bed of the present invention will be described in detail below in conjunction with the section view of the prefabricated short slab 2. Such as figure 1 As shown, each prefabricated short board is elastically supported by four built-in vibration isolators 5 and four built-in vibration isolators 30, and the adjacent prefabricated short boards are longitudi...

Embodiment 2

[0041] Such as Figure 5 The difference between the prefabricated short-slab floating ballast bed of the present invention and the first embodiment is that the Figure 6 The prefabricated short boards of the structure shown are used as floating boards, and each prefabricated short board is provided with eight limiting grooves 15 that cooperate with elastic vibration isolators. For ease of description, the prefabricated short slabs are numbered 17, 18 and 19 in sequence. The structure of the prefabricated short slab floating ballast bed of the present invention will be described in detail below in conjunction with the section view of the prefabricated short slab 18. Such as Figure 5 As shown, the prefabricated short boards are elastically supported by four elastic vibration isolation devices 35 and four elastic vibration isolation devices 36, separated from the surface of the foundation 13, and the adjacent prefabricated short boards are connected longitudinally through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com