Shale gas reservoir hydraulic fracturing production increasing method

A hydraulic fracturing and shale gas reservoir technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., to improve the effect of hydraulic fracturing and increase the output of a single well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

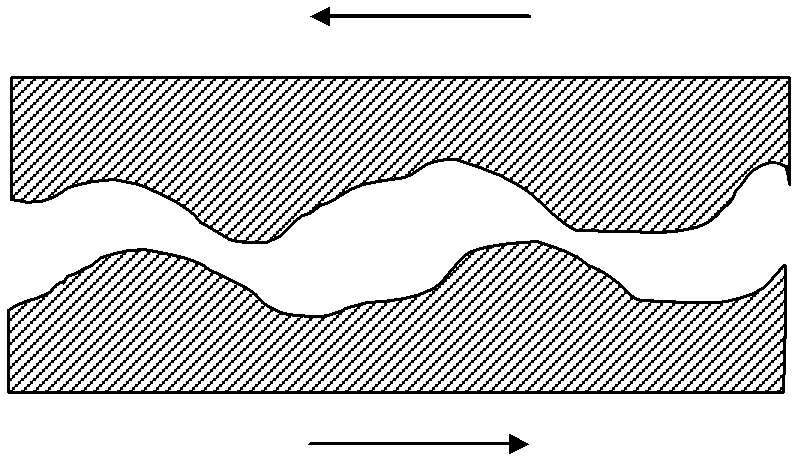

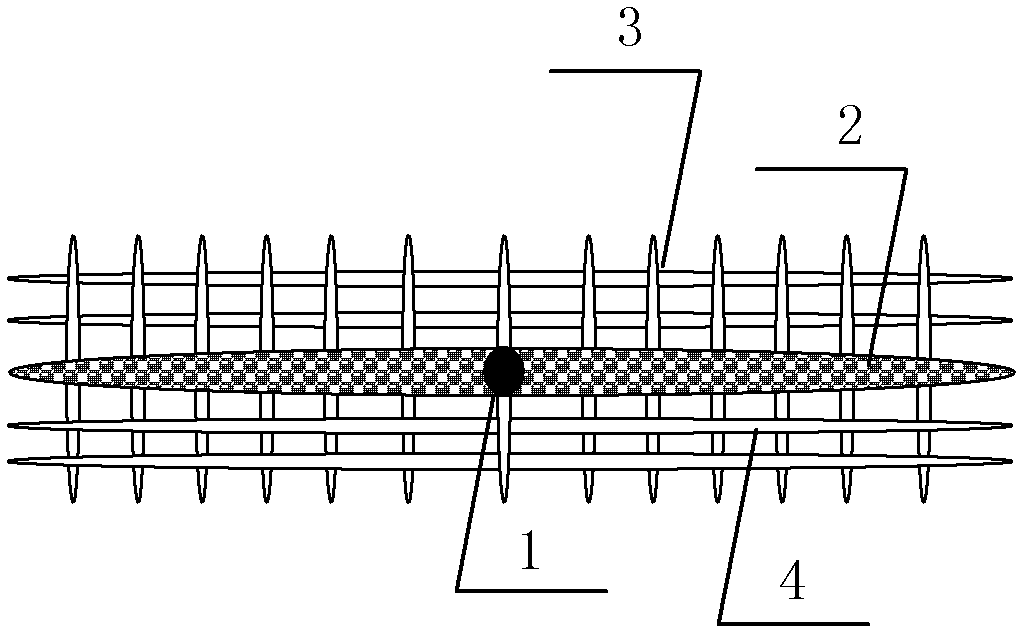

Method used

Image

Examples

Embodiment

[0035]Well A is a continental shale gas well. The fracturing fluid adopts the resistance-reducing water system. The proppant adopts 100-mesh ceramsite + 40 / 70-mesh ceramsite + trailing 30 / 50-mesh ceramsite. The fracturing method adopts "multi-slug injection". -Temporary plugging-pressure suppression in the seam-induced steering"technology.

[0036] 1) The displacement of the pre-fluid joint-making stage is first increased to 6m 3 / min, then the displacement continues to increase to 8m 3 / min

[0037] 2) Alternate injection stage of pad fluid and 100-mesh ceramsite slug, initial proppant concentration 60kg / m 3 , when the first-stage 100-mesh ceramsite slug and the pre-displacement fluid pumping ended, the wellhead construction pressure monitoring showed a pressure drop of 3.1MPa, and the displacement rose to 11m 3 / min, the proppant concentration rises to 90kg / m 3 , the proppant concentration rises to 120kg / m after injecting the second-stage pre-displacement fluid 3 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com