Air distribution mechanism for engine

A technology of valve train and engine, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as insufficient air intake, and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

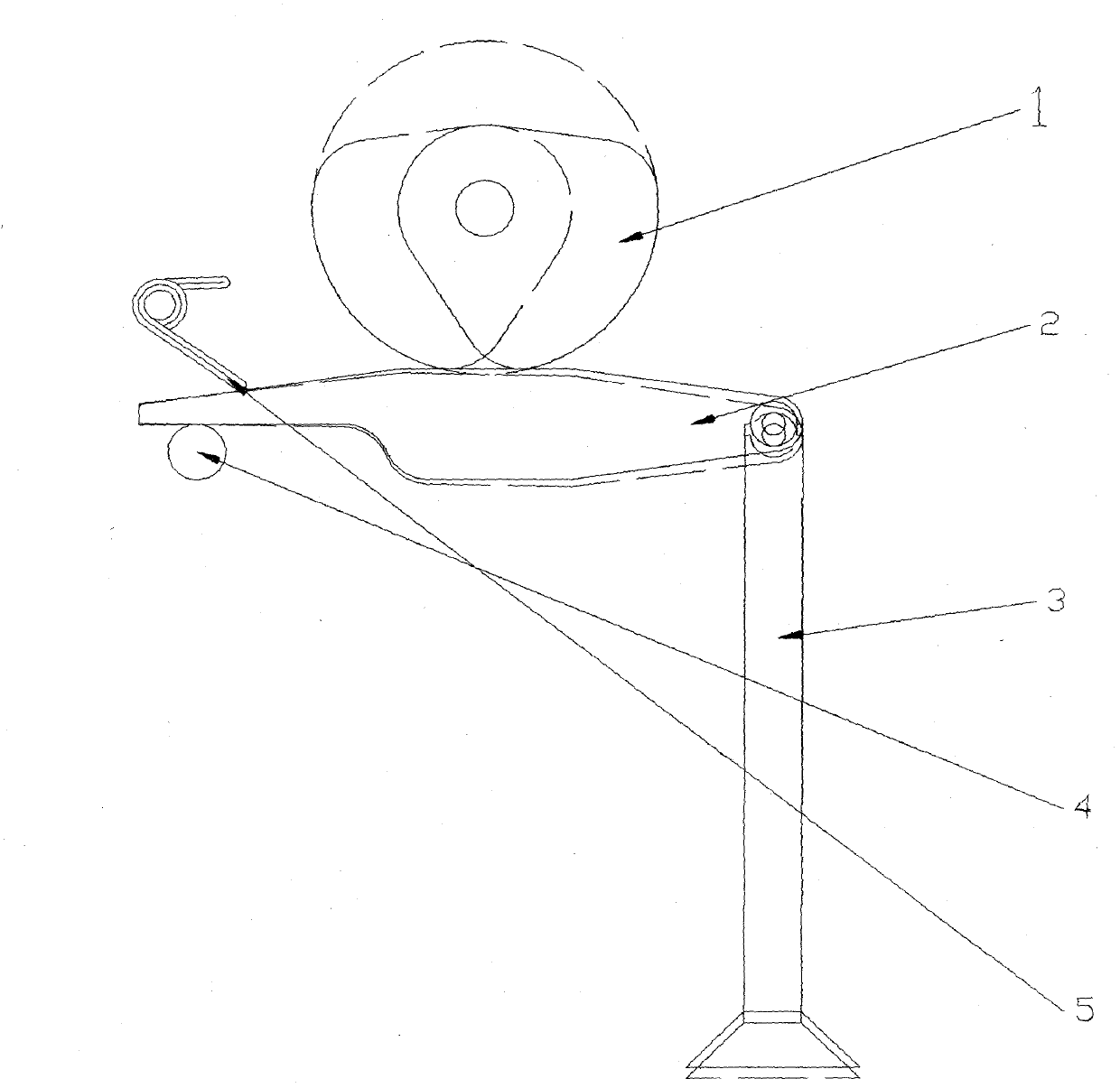

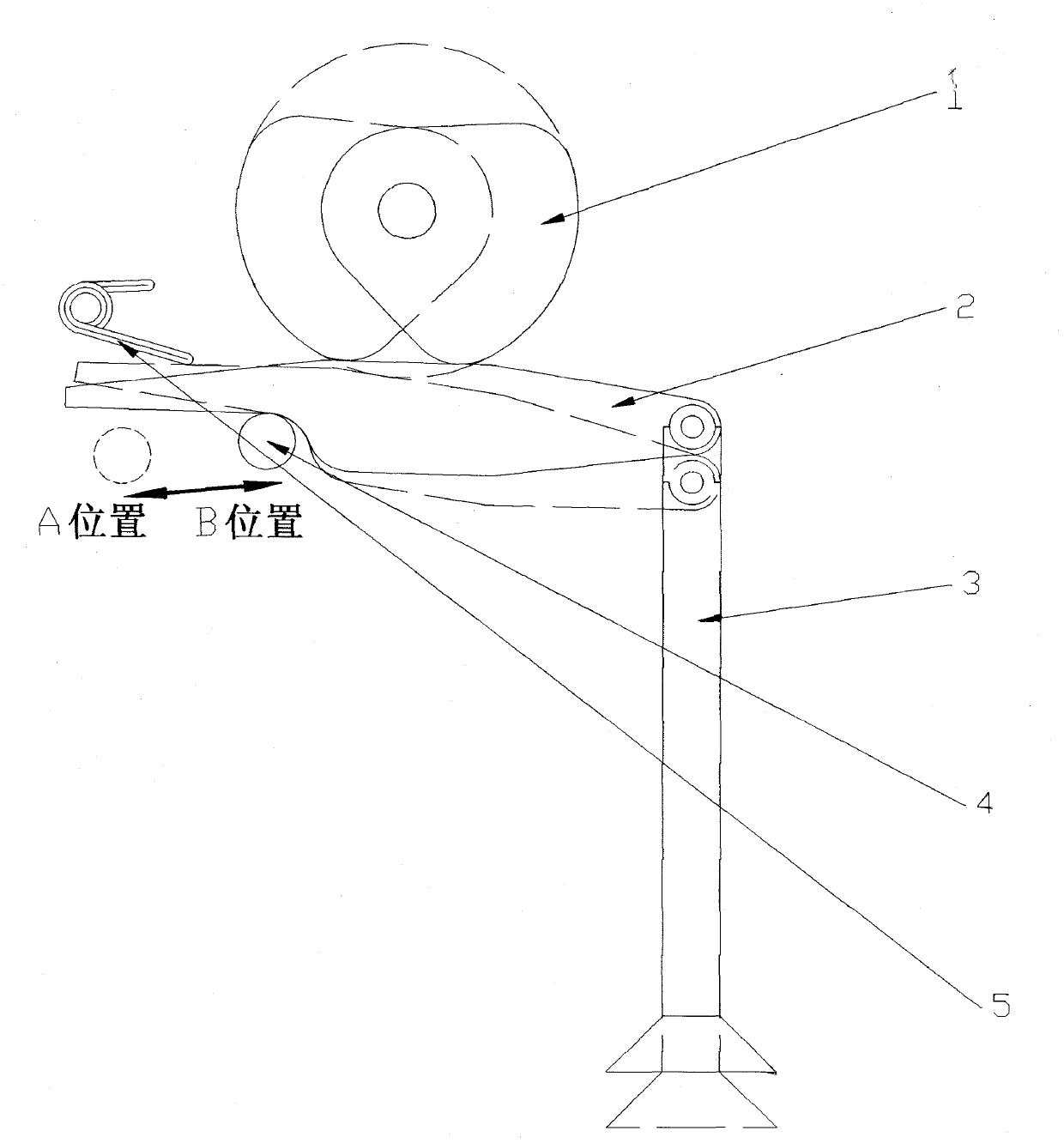

[0010] exist figure 1 In the shown embodiment, the sector cam (1), rocker arm (2), valve (3), rocker fulcrum (4), and return spring (5) are installed in sequence, and the valve (3), rocker fulcrum (4), return The bit spring (5) is installed on the engine cylinder head, and the rocking arm (2) is movably connected with the valve (3). One end of the return spring (5) presses the rocking arm to ensure that the rocking arm (2) is not separated from the rocking arm fulcrum (4) during work. The rocking arm fulcrum (4) can slide by the design track on the cylinder head. The fulcrum of the rocker arm is on the far left, and the valve stroke and valve opening angle are at the minimum state.

[0011] When the position of the fulcrum (4) of the rocker arm remains unchanged, the fan-shaped cam (1) rotates clockwise under the drive of the main shaft of the engine. When the fan-shaped cam (1) contacts the rocker arm (2), the rocker arm (2) rotates The rocker arm fulcrum (4) rotates back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com