An Engine Electronic Injection Control System Based on Torque Control

A control system and torque control technology, applied in the direction of engine control, machine/engine, electrical control, etc., can solve the problems of increasing development cost, development cycle of supercharged engine control system, and tedious calibration work, and achieve the effect of good acceleration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

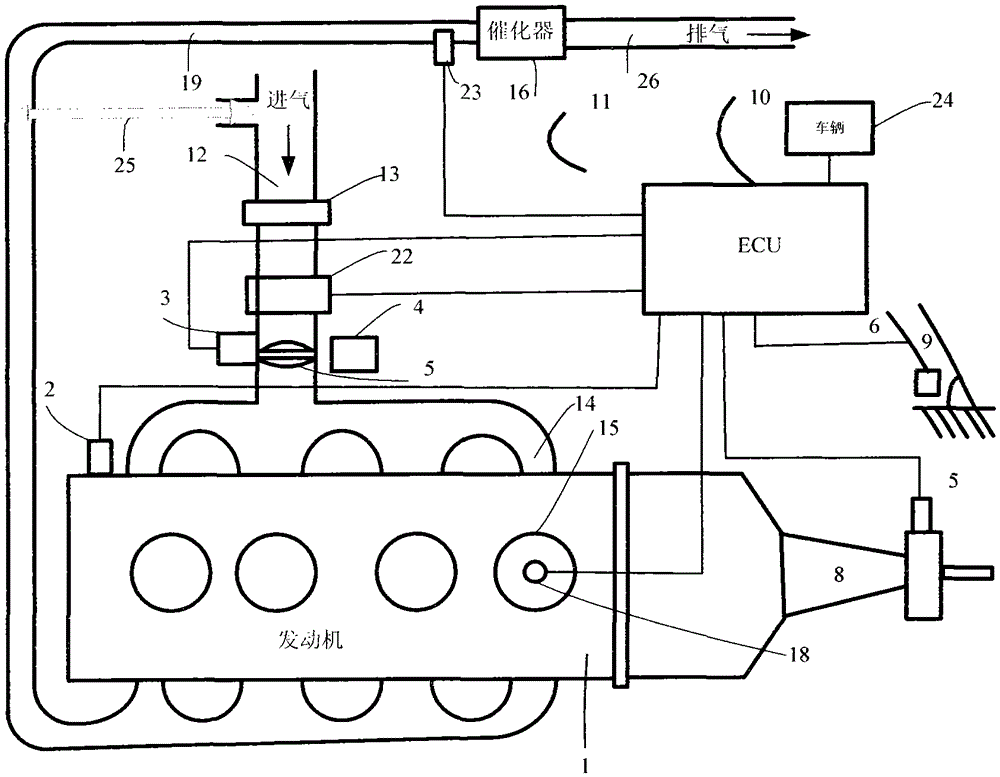

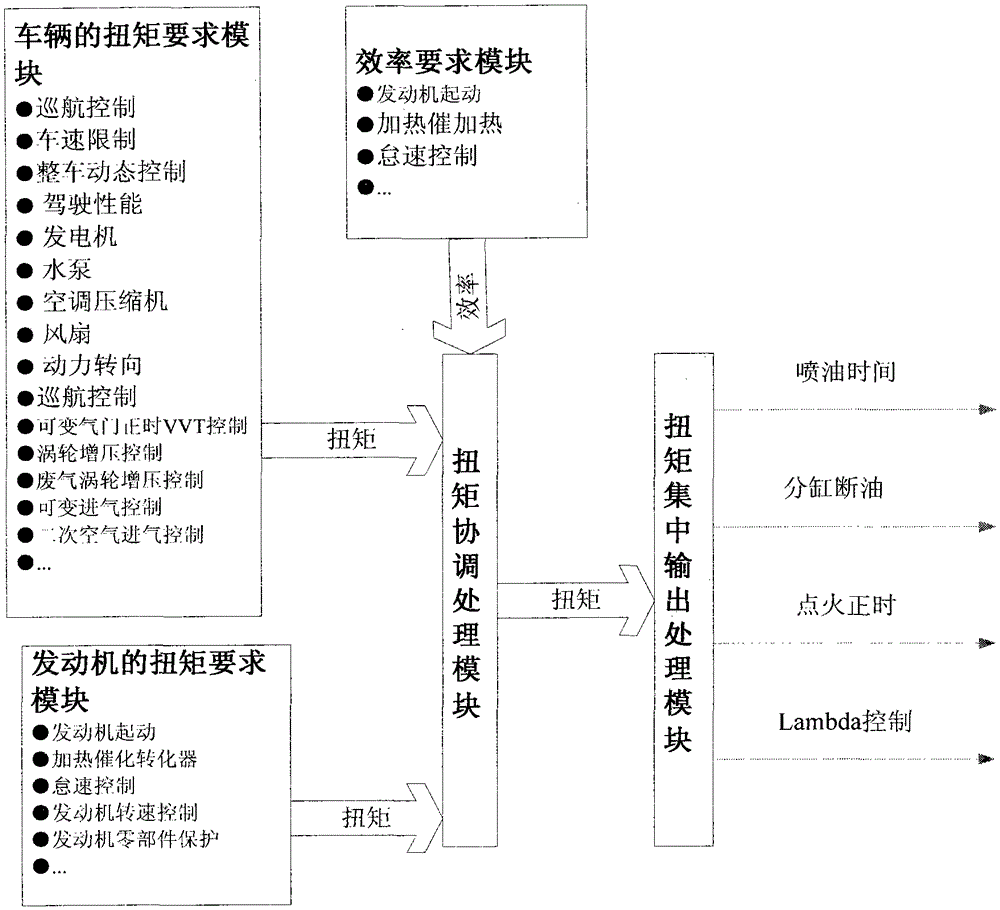

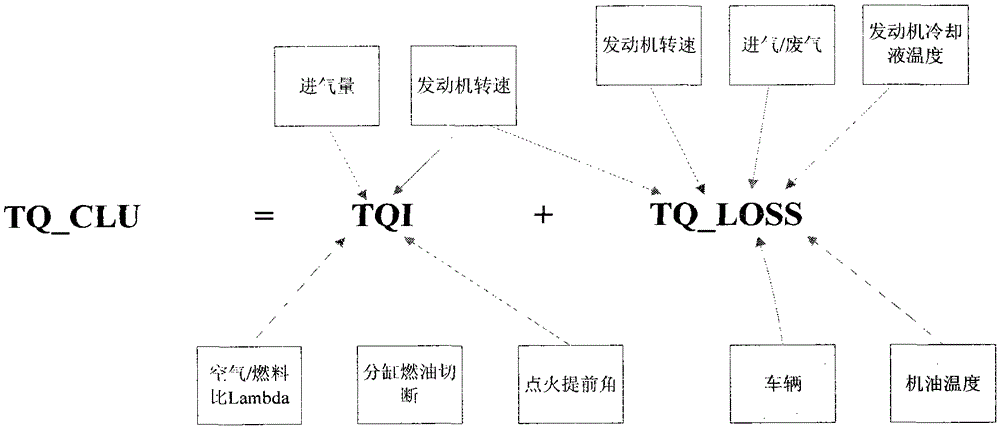

[0062] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0063] Referring to accompanying drawing, control flow of the present invention:

[0064] a. The system initializes the resources used by the system and the state of sensors and actuators when the system initializes the processing module M1;

[0065] b. Run and read the system configuration module M2, determine the corresponding function to be realized by the system, and set the corresponding flag according to the function of the system;

[0066] c. Determine whether the system anti-theft control flag is set to 1. Setting 1 indicates that if it is set to 1, the anti-theft processing module M23 will be turned on. The anti-theft processing module M3 will judge whether it is a normal user start. The anti-theft normal flag is set to 1, and the system jumps to step d. continue to run;

[0067] If it is not started by a norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com