Household appliance panel, household appliance, and processing method of household appliance panel

A technology of household appliances and processing methods, applied in the direction of casing/cabinet/drawer parts, etc., to achieve the effect of enriching materials and broadening the road of diversified development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to solve the problem of using metal materials for the panels of household appliances, a technical proposal for panels of household appliances, household appliances and a processing method for panels of household appliances is proposed.

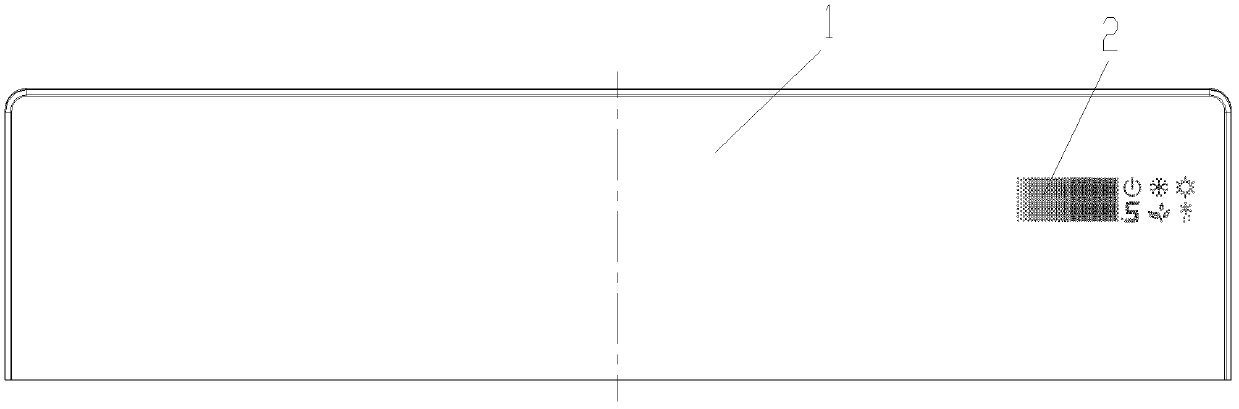

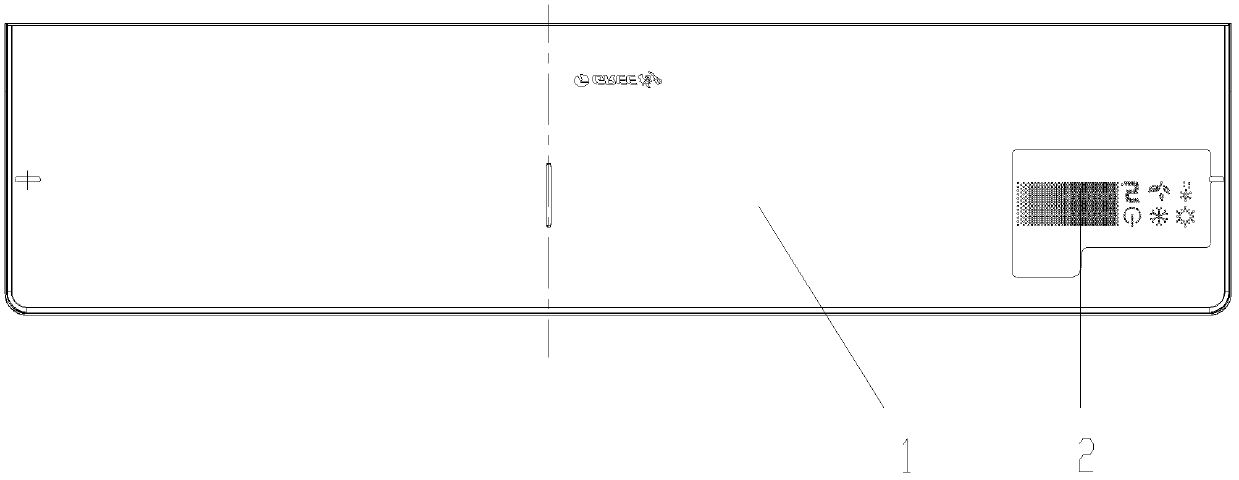

[0030] In the example, as Figures 1 to 5 As shown, exposes:

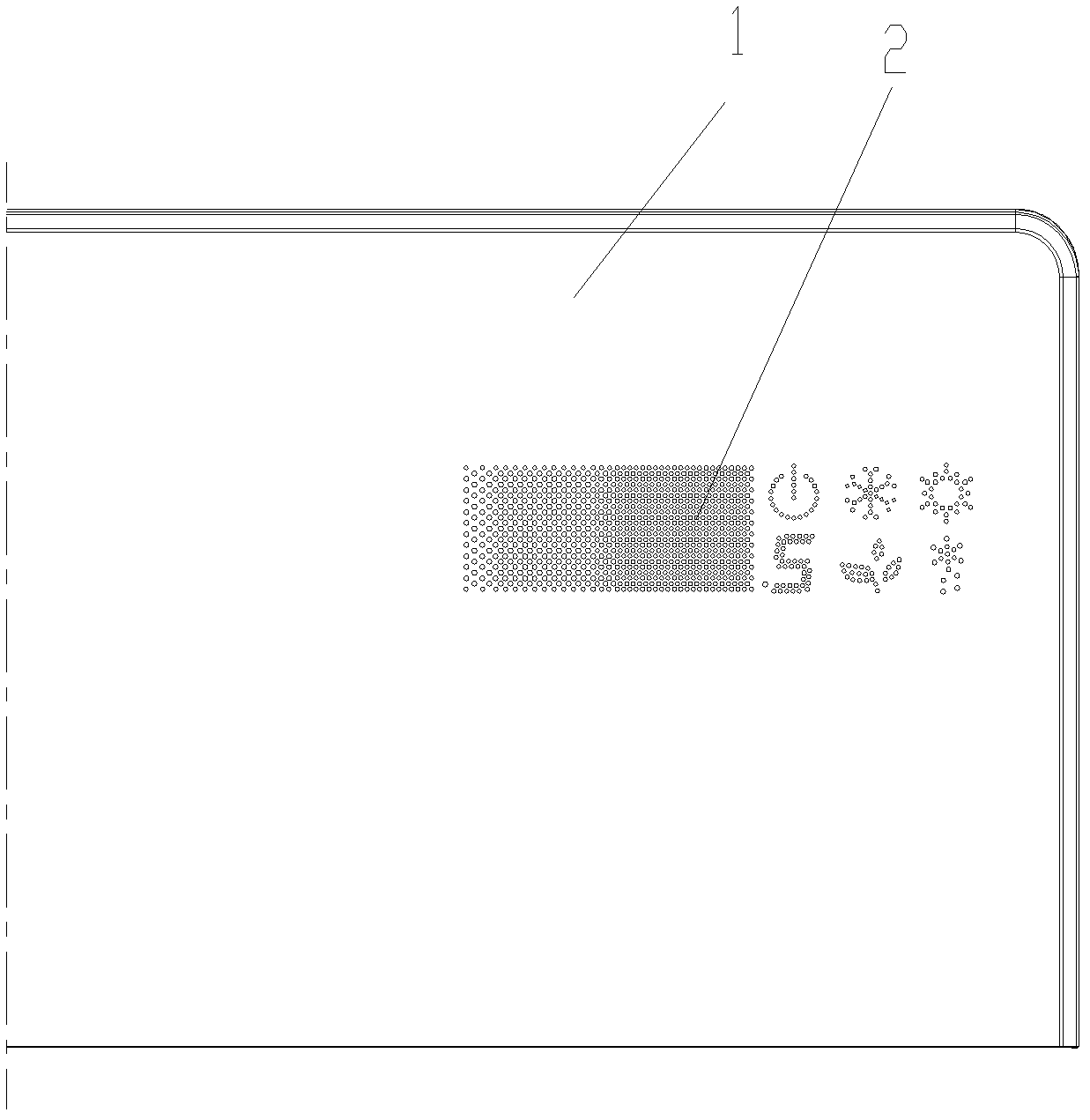

[0031] A household appliance panel 1 , wherein the household appliance panel 1 is a metal panel; the display area 2 of the metal panel is provided with a plurality of light-transmitting pores 20 .

[0032] In a preferred embodiment, the diameter of the light-transmitting pores 20 ranges from 0.5 mm to 5 mm.

[0033] In particular, the diameter of the light-transmitting pores 20 ranges from 0.8 mm to 2 mm.

[0034] A light-transmitting filling substance is arranged in the light-transmitting pores 20 .

[0035] The display area 2 includes a digital display area 21 and a pattern display area 22. The light-transmitting pores 20 in the digital display area 21 are arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com