A kind of construction method of polyurethane insulation layer

A construction method and insulation layer technology, applied in the direction of insulation, walls, buildings, etc., can solve the problems of difficult work, damage to the wall, etc., and achieve the effect of fast construction, guaranteed insulation quality, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The following is the specific construction method of the present invention, which is not a limitation to the claims. Changes made by those skilled in the art based on the relevant knowledge in the field are also within the protection scope of the present invention.

[0027] The plate used in the present invention is a PVC exterior wall hanging plate, the combustion performance is B2 level, and the thickness is 6mm;

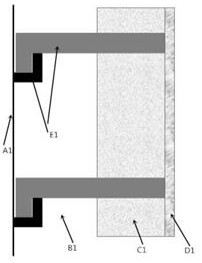

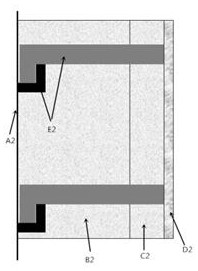

[0028] For buildings in Jinan (North) area, according to the construction requirements, a layer of 30cm thick insulation layer needs to be constructed on the outer wall of the six-storey building. After the building material processing factory produces the 1.0m*1.0m outer panel, the four front-end protruding connecting rods are bonded At the four corners of the outer plate, the end without protrusions is the bonding end;

[0029] Then mix material A and material B evenly and spray it to the inner surface quickly. The foaming time is 20-30s, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com