Machining method of floating cylinder

A floating sleeve and processing method technology, applied in the field of mechanical processing and manufacturing, can solve problems such as difficult clamping, and achieve the effect of ensuring processing quality and improving process solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

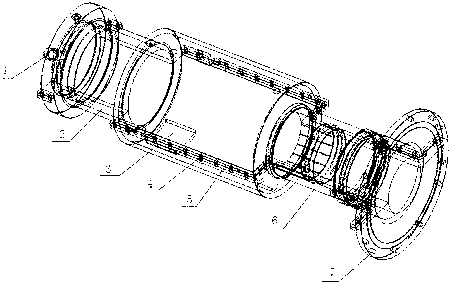

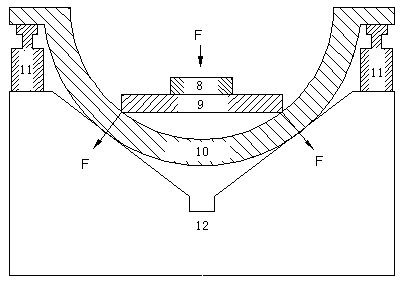

[0034] Such as Figure 1~3 As shown, the floating sleeve to be processed is in the shape of a sleeve, and the two ends are designed with journals and end flanges. The floating sleeve has an upper and lower half structure. The flange 5 is provided with a connection hole 4, and the upper half and the lower half of the floating sleeve are fastened by bolts.

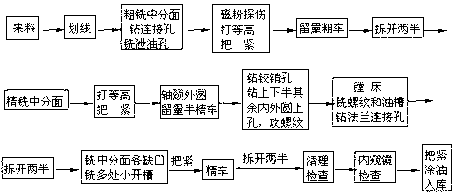

[0035] The present invention is a processing method for the above-mentioned floating sleeve, comprising the following steps:

[0036] (1) The upper half and the lower half of the workpiece to be processed are sequentially clamped on the machine tool for rough machining, specifically: rough milling the upper half of the workpiece and the mid-section of the lower half of the workpiece, and pre-drilling the mid-section method of the upper half of the workpiece The connection hole 4 on the blue 5, the drain hole on the lower half of the pre-milled workpiece;

[0037] Wherein: the upper half of the workpiece or the lower half o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com