cutting device

A cutting and conveying device technology, applied in the directions of transportation and packaging, metal processing, sending objects, etc., can solve the problems of blockage, transmission and processing device interference, interference, etc., to optimize the movement process, simple transfer and speed adaptation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

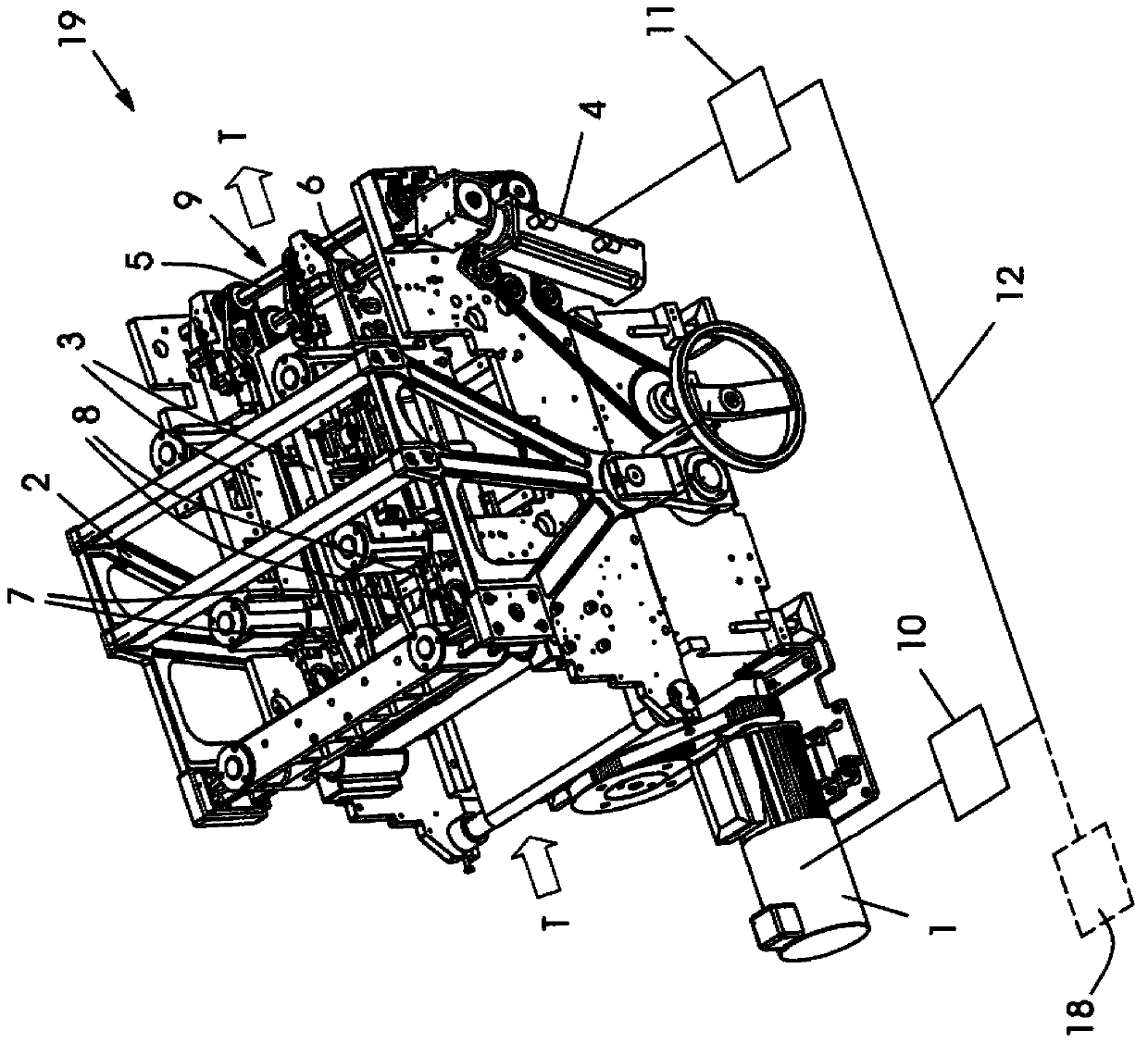

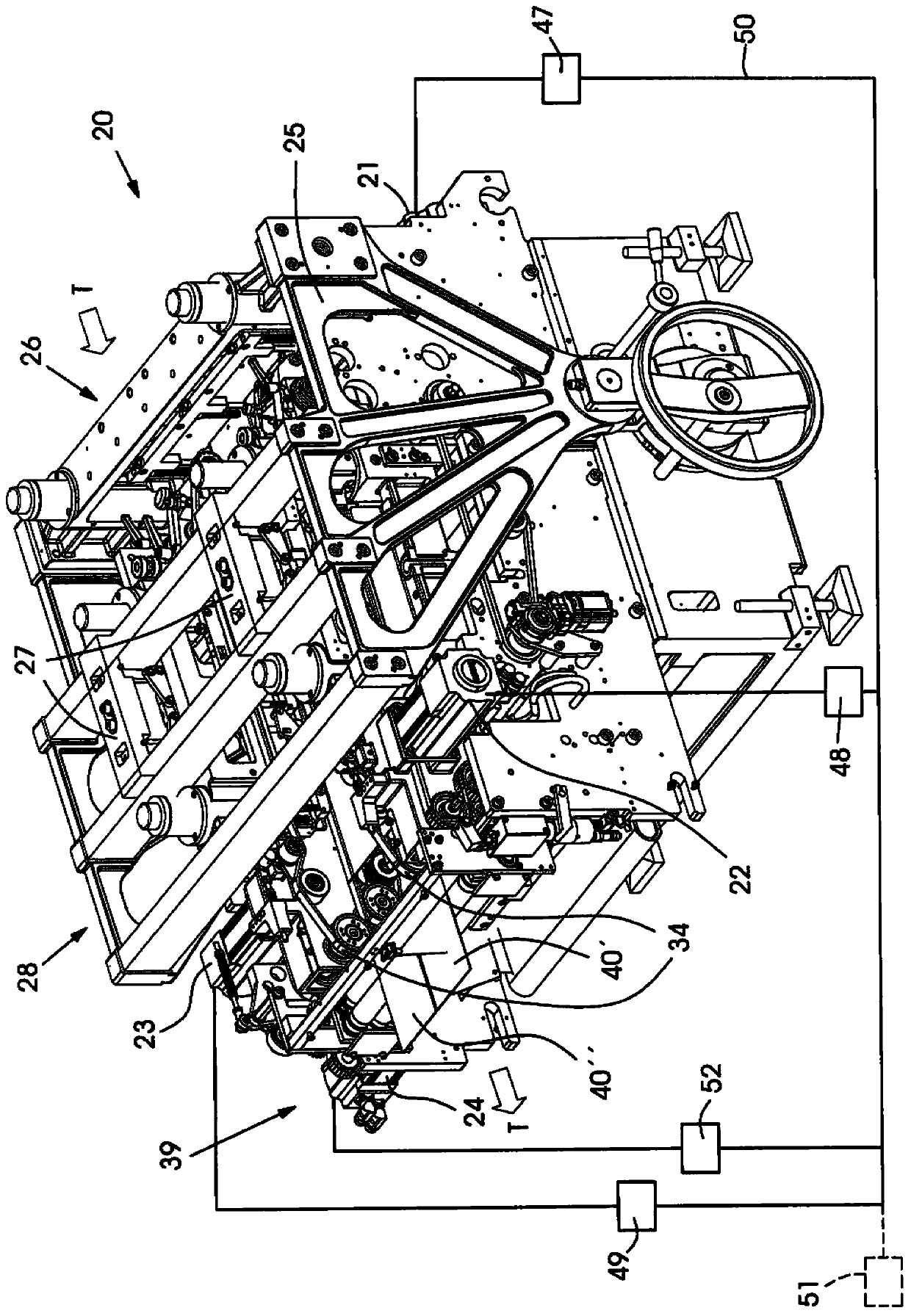

[0019] Figure 1a A representative example of a cutting device 19 for edge cutting according to the prior art is shown in FIG. 1, which has a separate driving device. The first driving motor 1 realizes the movement of the upper cutter bridge 2, and the upper cutter is fixed on the upper cutter bridge. The arrow T indicates the running direction of the product. The second drive motor 4 drives the belts 7, 8 of the conveying system 9 via the consecutive first and second drive shafts 5, 6. The two drive motors 1, 4 are provided with control units 10, 11, which can communicate with each other by means of a connection to exchange data and / or control signals. Furthermore, the connection 12 can also lead to a central machine control unit 18.

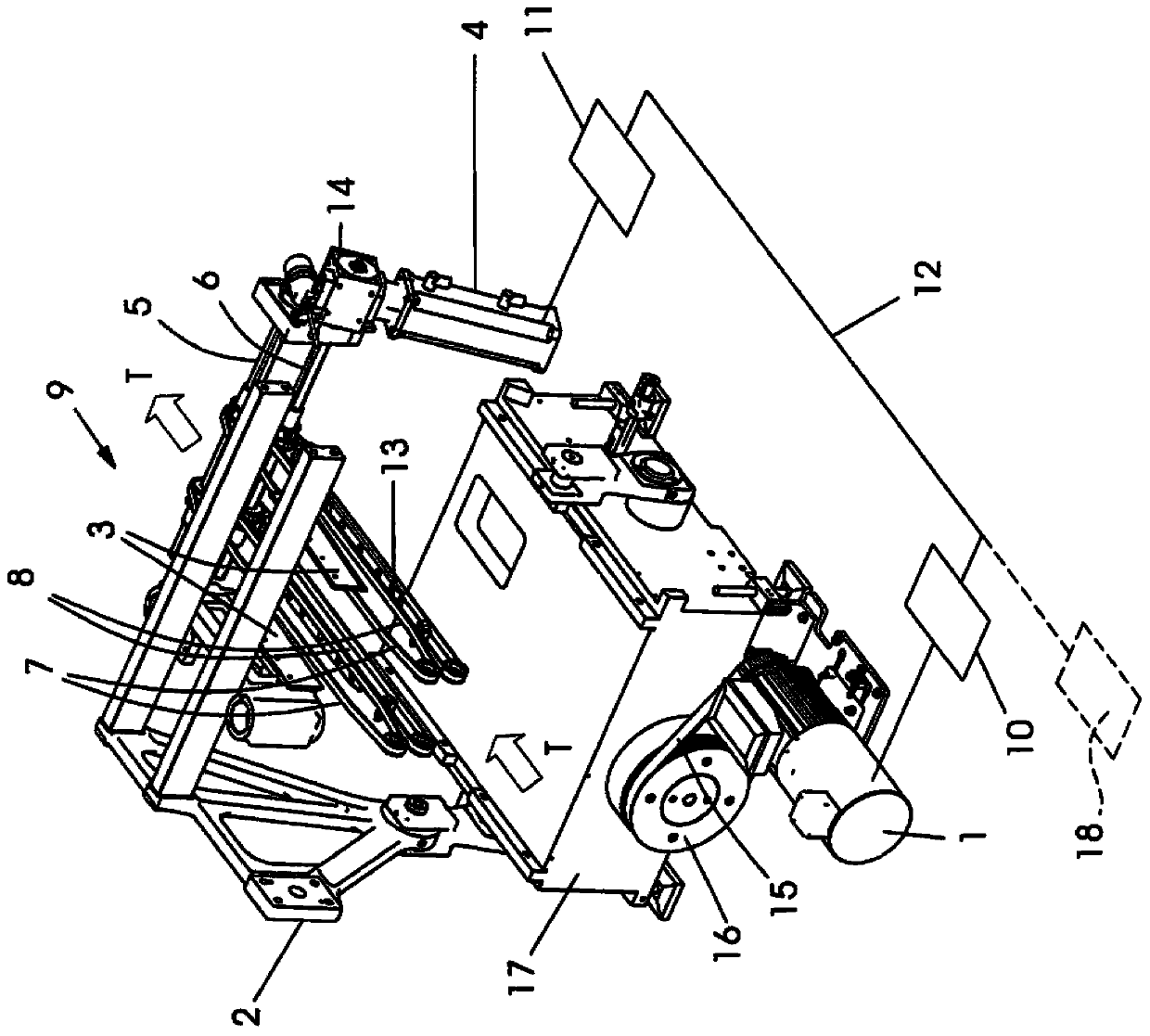

[0020] in Figure 1b It can be seen that the main components of the drive that realize the two motion sequences. The first drive motor 1 realizes the vertical non-uniform oscillating movement of the upper cutter bridge 2 by means of the toothed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com