Rail passenger car multi-function board

A rail passenger car, multi-functional technology, applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., can solve the problem that the bridge structure can not meet the requirements, achieve good drainage function, improve production efficiency, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

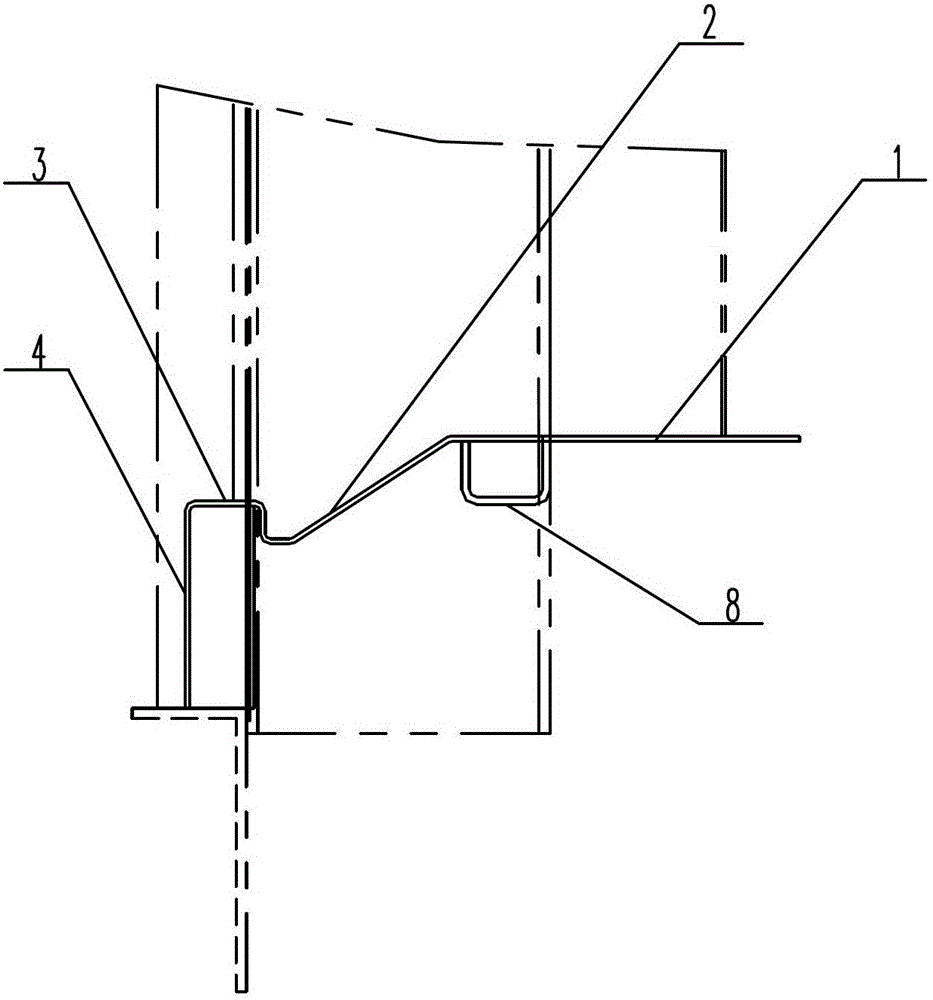

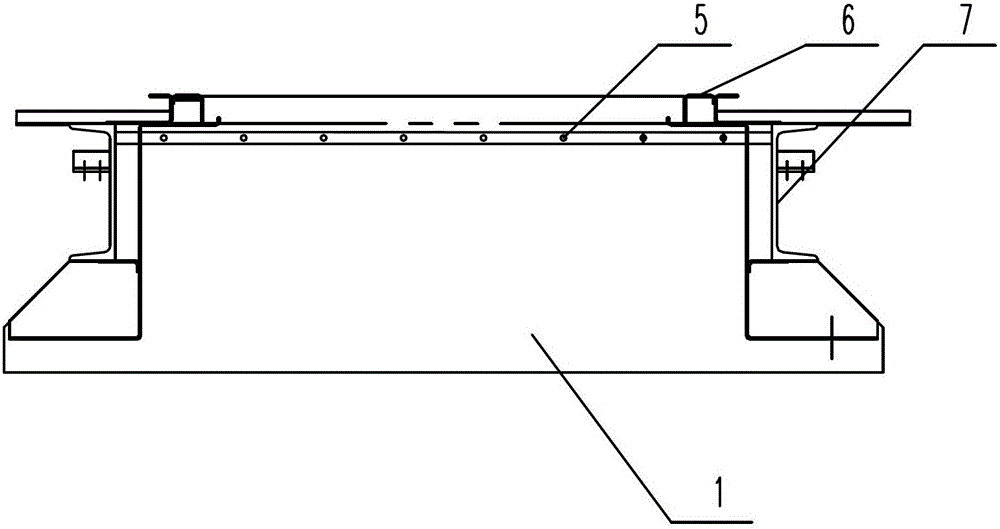

[0016] like figure 1 , figure 2 As shown in the figure, the multi-functional cross-board of the rail passenger car in this embodiment is formed by bending a whole piece of steel plate after cutting. The board surface 1 is about 51mm higher than the sill surface 3, the bottom surface of the waterproof groove 2 is about 25mm lower than the sill surface, the sill vertical plate 4 is perpendicular to the sill surface 3, and the bottom of the waterproof groove 2 is provided with a drainage hole 5 along its longitudinal direction. The aperture is 10mm), the end of the sill face 3 and the sill vertical plate 4 are welded and fixed to the door frame column 6, and the end of the waterproof groove 2 is welded and fixed to the end wall channel steel 7. like figure 1 As shown, the groove wall of the waterproof groove 2 close to the rocker surface 3 is perpendicular to the rocker surface, and the groove wall of the waterproof groove 2 close to the bridge surface 1 is an inclined surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com