Shoe gap regulator for railway vehicle

A technology for brake shoe clearance and rail vehicles, which is applied in the field of brake shoe clearance adjusters for rail vehicles, can solve the problems of high cost, complex shape of parts, high machining requirements, etc., and achieve the effect of improving efficiency and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

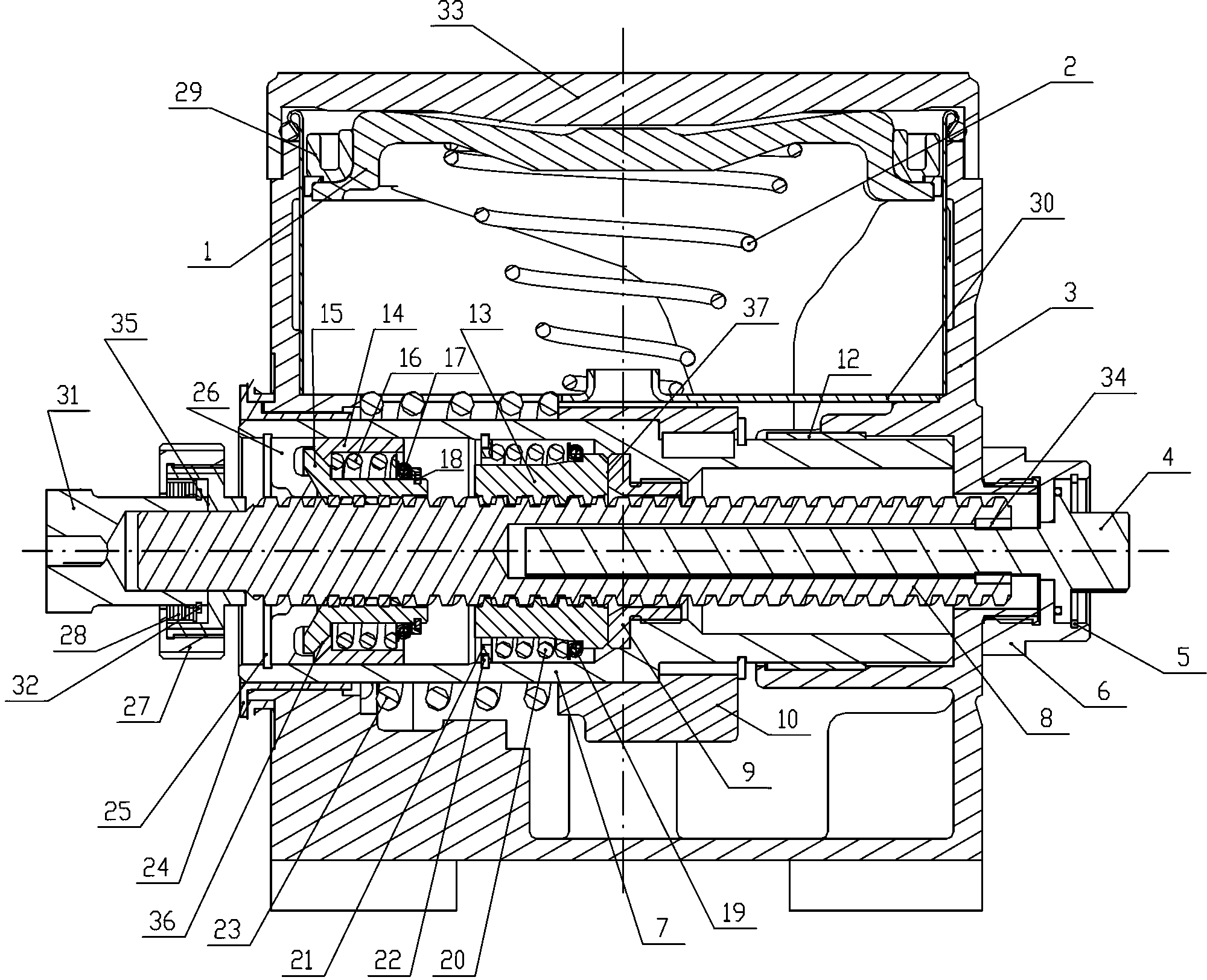

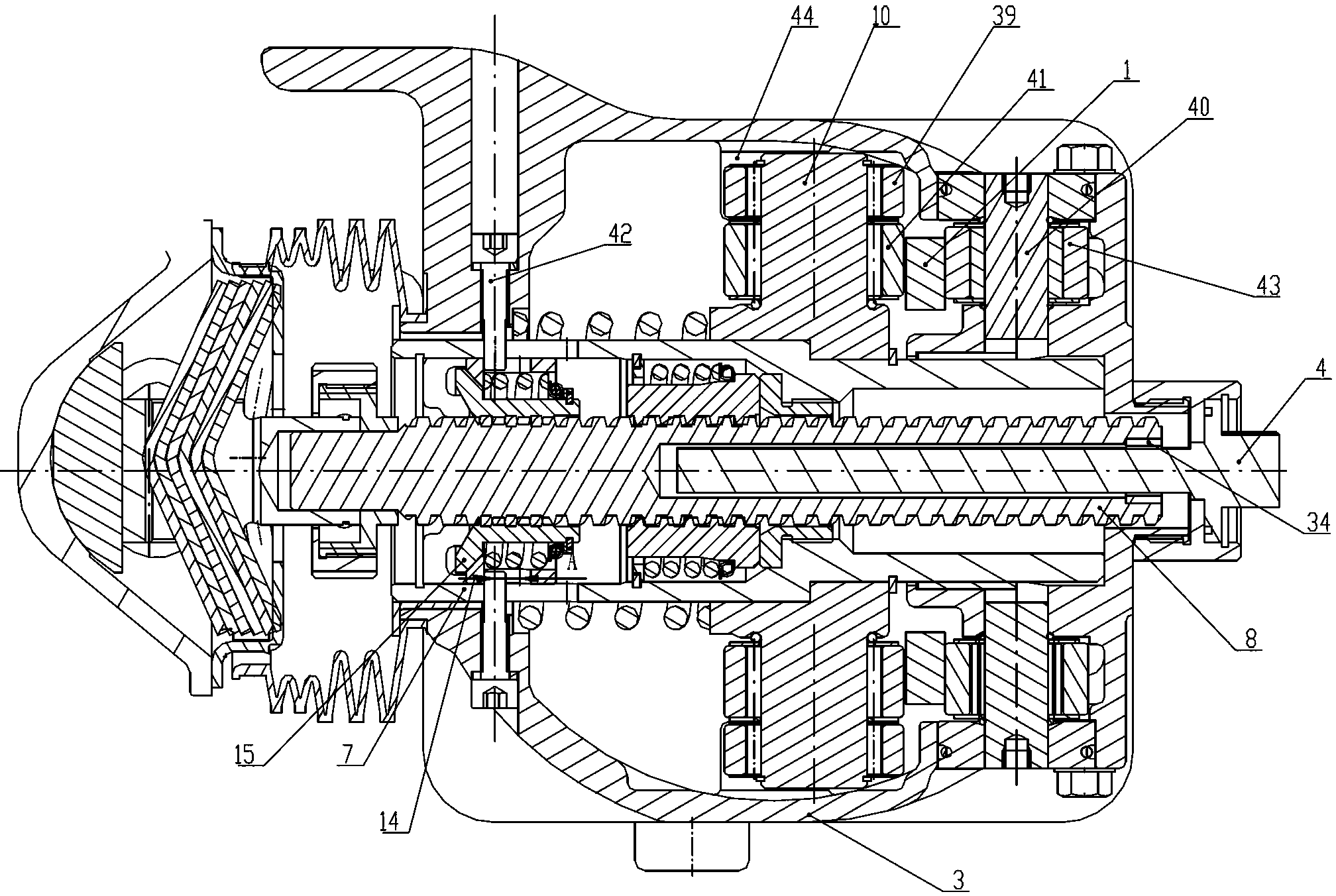

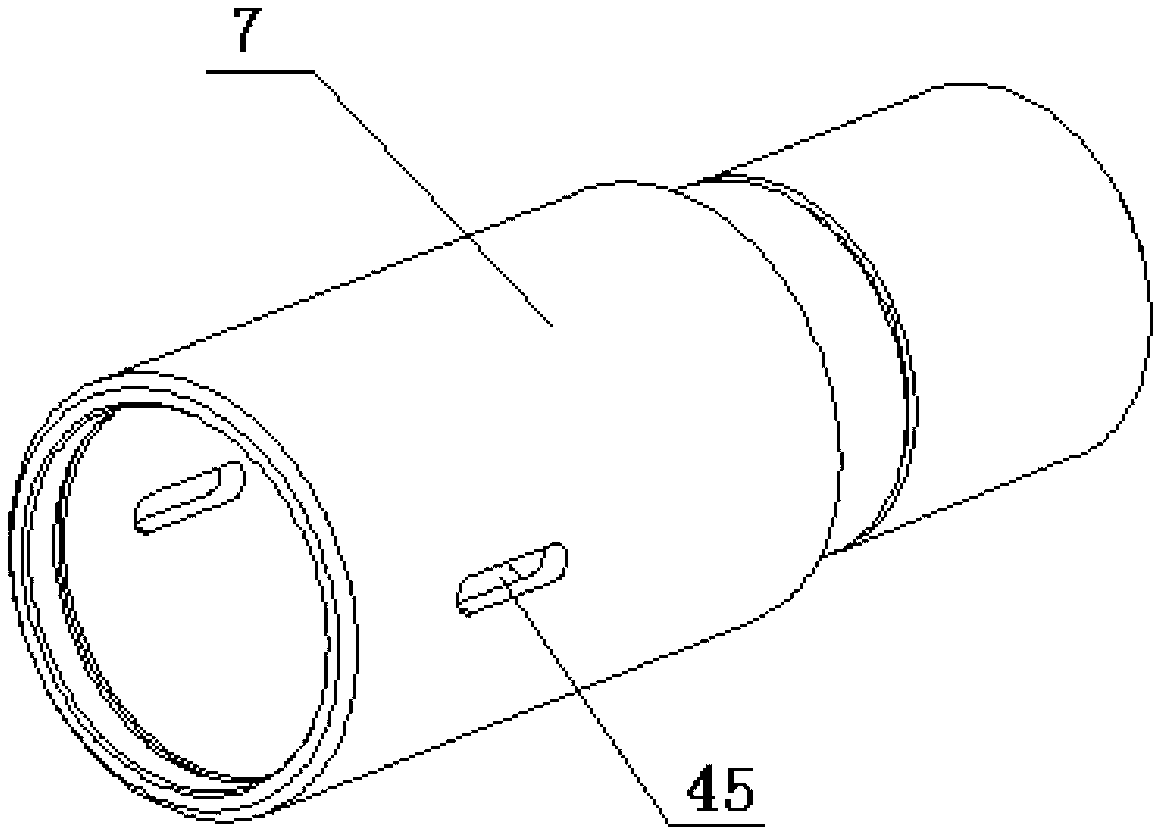

[0028] Such as figure 1 , figure 2 As shown, the brake shoe clearance adjuster for rail vehicles consists of: a box body 3, a wedge block 1, a cross shaft 10, an adjustment sleeve 7, and a screw rod 8, and the screw rod 8 is threadedly connected to the adjustment sleeve 7 Inside the first nut 15 and the second nut 13, the first nut 15 is located in front of the second nut 13, and the first nut 15 and the second nut 13 are respectively sleeved with a first return compression spring 16 and a second return compression spring 20, The cross shaft 10 is keyed to the adjustment sleeve 7, and the brake shoe clearance adjuster also includes: a limit sleeve 14 placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com