Method for extracting purple potato polysaccharide by utilizing ultrasonic wave synergistic with enzymatic method and application

A technology of enzymatic extraction and ultrasonic wave is applied in the field of food biochemistry to achieve the effects of wide sources, short shelf life and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

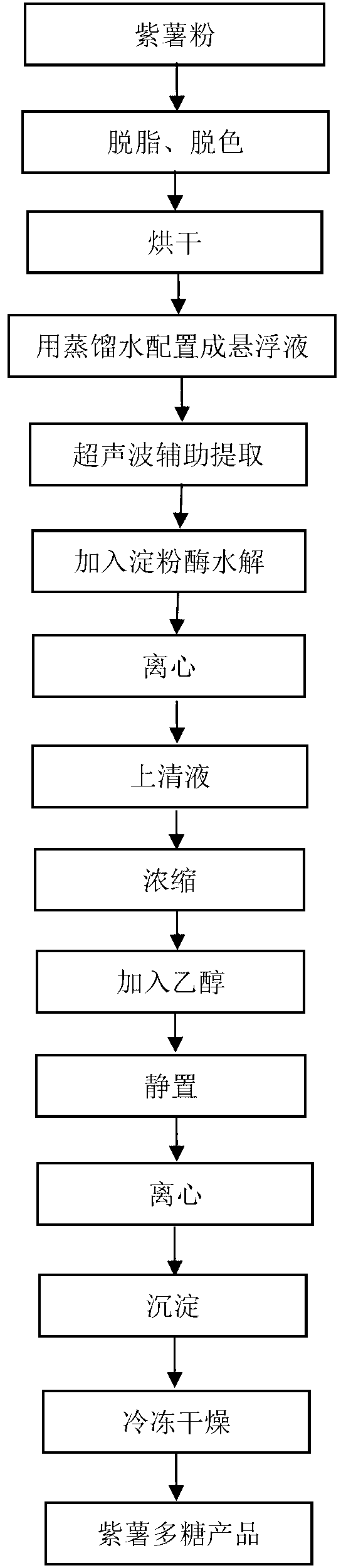

Method used

Image

Examples

Embodiment 1

[0031] Purple sweet potato powder was prepared into 10% (w / v, g / mL) suspension with 95% (v / v, mL / mL) ethanol, extracted at 50°C for 6h for degreasing and decolorization, and then dried at 50°C Dry, prepare the dried degreased and decolorized purple sweet potato powder with distilled water to make a 3% (w / v, g / mL) solution, stir evenly and use 25kHz ultrasonic-assisted extraction at 55°C for 50min, the ultrasonic power is 180W, ultrasonic-assisted extraction After the end, add α-amylase, the amount of enzyme added is 100U / g, enzymatically hydrolyze at 50°C for 4h, centrifuge to obtain the supernatant after the enzymolysis, and concentrate the supernatant to a polysaccharide content of 5% (w / v, g / mL), add 95% (v / v, mL / mL) ethanol, keep the ethanol concentration in the mixture at 85% (v / v, mL / mL), centrifuge after standing for 1h, collect the precipitate and freeze-dry, that is A powdered purple sweet potato polysaccharide product is obtained. The extraction rate of purple pota...

Embodiment 2

[0033] Purple sweet potato powder was prepared into a 20% (w / v, g / mL) suspension with 95% (v / v, mL / mL) ethanol, extracted at 65°C for 5 hours for degreasing and decolorization, and then dried at 60°C Dry, prepare the dried degreased and decolorized purple sweet potato powder with distilled water to make a 4% (w / v, g / mL) solution, stir evenly and use 25kHz ultrasonic-assisted extraction at 65°C for 40min, the ultrasonic power is 210W, ultrasonic-assisted extraction After the end, add α-amylase, the amount of enzyme added is 300 / g, enzymatically hydrolyze at 55°C for 3h, centrifuge to obtain the supernatant after the enzymolysis, and concentrate the supernatant to a polysaccharide content of 5% (w / v, g / mL), add 95% (v / v, mL / mL) ethanol, keep the ethanol concentration in the mixture at 90% (v / v, mL / mL), centrifuge after standing for 1h, collect the precipitate and freeze-dry, that is A powdered purple sweet potato polysaccharide product is obtained. The extraction rate of purpl...

Embodiment 3

[0035] Purple sweet potato powder was prepared into a 30% (w / v, g / mL) suspension with 95% (v / v, mL / mL) ethanol, extracted at 80°C for 4 hours for degreasing and decolorization, and then dried at 70°C Dry, prepare the dried degreased and decolorized purple sweet potato powder with distilled water to make a 5% (w / v, g / mL) solution, stir evenly and use 25kHz ultrasonic-assisted extraction at 75°C for 30min, the ultrasonic power is 250W, ultrasonic-assisted extraction After the end, add α-amylase, the amount of enzyme added is 500U / g, enzymatically hydrolyze at 60°C for 2 hours, centrifuge to obtain the supernatant after the enzymolysis, and concentrate the supernatant to a polysaccharide content of 5% (w / v, g / mL), add 95% (v / v, mL / mL) ethanol, keep the ethanol concentration in the mixture at 95% (v / v, mL / mL), centrifuge after standing for 1h, collect the precipitate and freeze-dry, that is A powdered purple sweet potato polysaccharide product is obtained. The extraction rate of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap