Transparent heat-insulation stone material

A stone and transparent technology, applied in thermal insulation, building components, climate change adaptation, etc., can solve the problems of heavy weight, poor thermal insulation effect, inconformity with energy saving and consumption reduction, etc., and achieve good thermal insulation performance and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

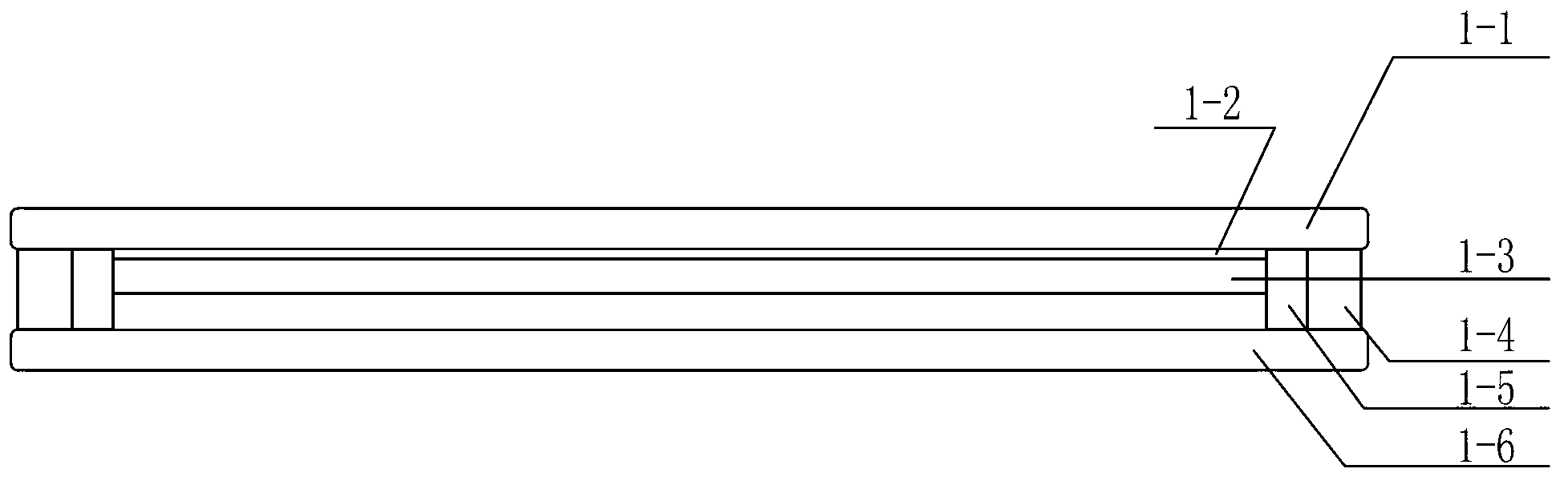

[0021] Such as figure 1 As shown, the transparent thermal insulation stone includes stone 1-3, the first glass layer 1-1 and the second glass layer 1-6 are respectively arranged on the front and back of stone 1-3, the front of stone 1-3 and the first glass layer One surface of the layer 1-1 is connected by the first PVB adhesive film 1-2, the first glass layer 1-1 and the second glass layer 1-6 are connected by the edge structural glue 1-4, and the first glass layer An aluminum spacer 1-5 is set between the 1-1 and the second glass layer 1-6, and the interior of the aluminum spacer 1-5 is filled with molecular sieves; the first glass layer 1-1 and the second glass layer 1-6 are tempered Glass or tempered glass.

Embodiment 2

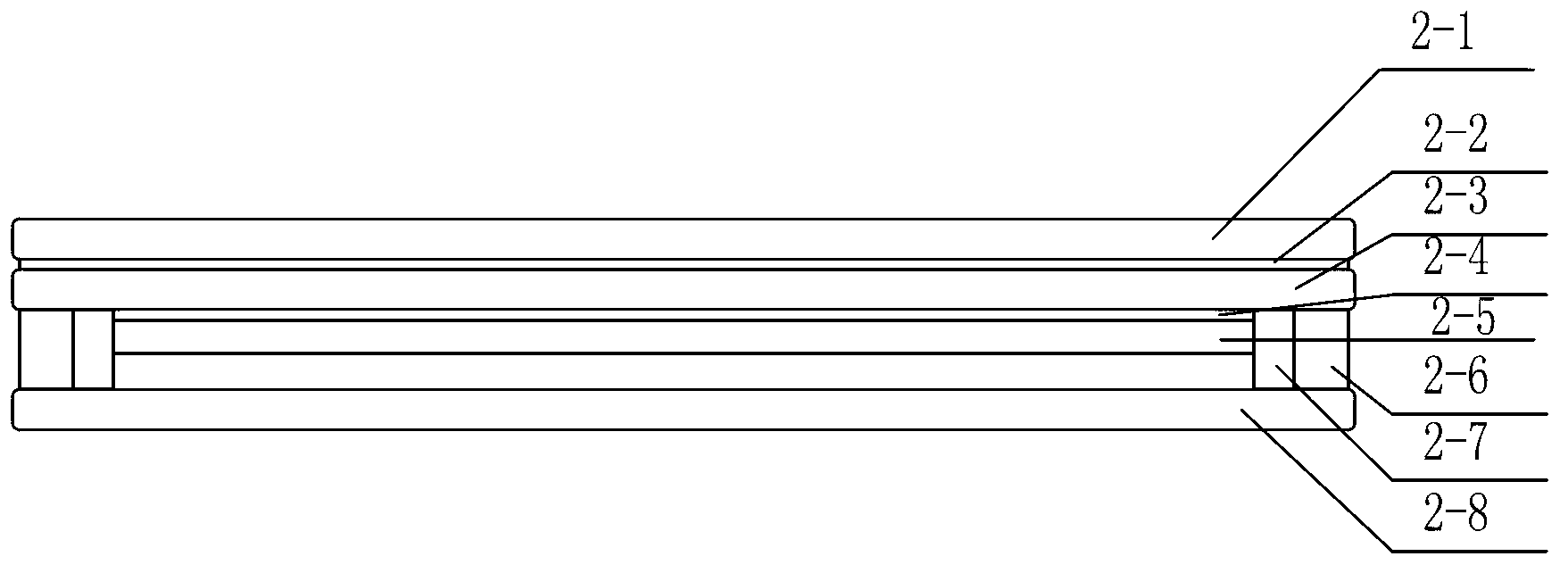

[0023] Such as figure 2 As shown, the transparent insulating stone includes a stone 2-5, and the first glass layer 2-3 and the second glass layer 2-8 are respectively arranged on the front and back of the stone 2-5, and the front of the stone 2-5 and the first glass layer One surface of the layer 2-3 is connected by the first PVB adhesive film 2-4, and the third glass layer 2-1 is connected by the second PVB adhesive film 2-2 on the other surface of the first glass layer 2-3; The first glass layer 2-3 and the second glass layer 2-8 are connected through the edge structural glue 2-6, and an aluminum spacer is set between the first glass layer 2-3 and the second glass layer 2-8 2-7, the inside of the aluminum spacer 2-7 is filled with molecular sieve; the first glass layer 2-3, the second glass layer 2-8 and the third glass layer 2-1 are made of tempered glass or semi-tempered glass.

Embodiment 3

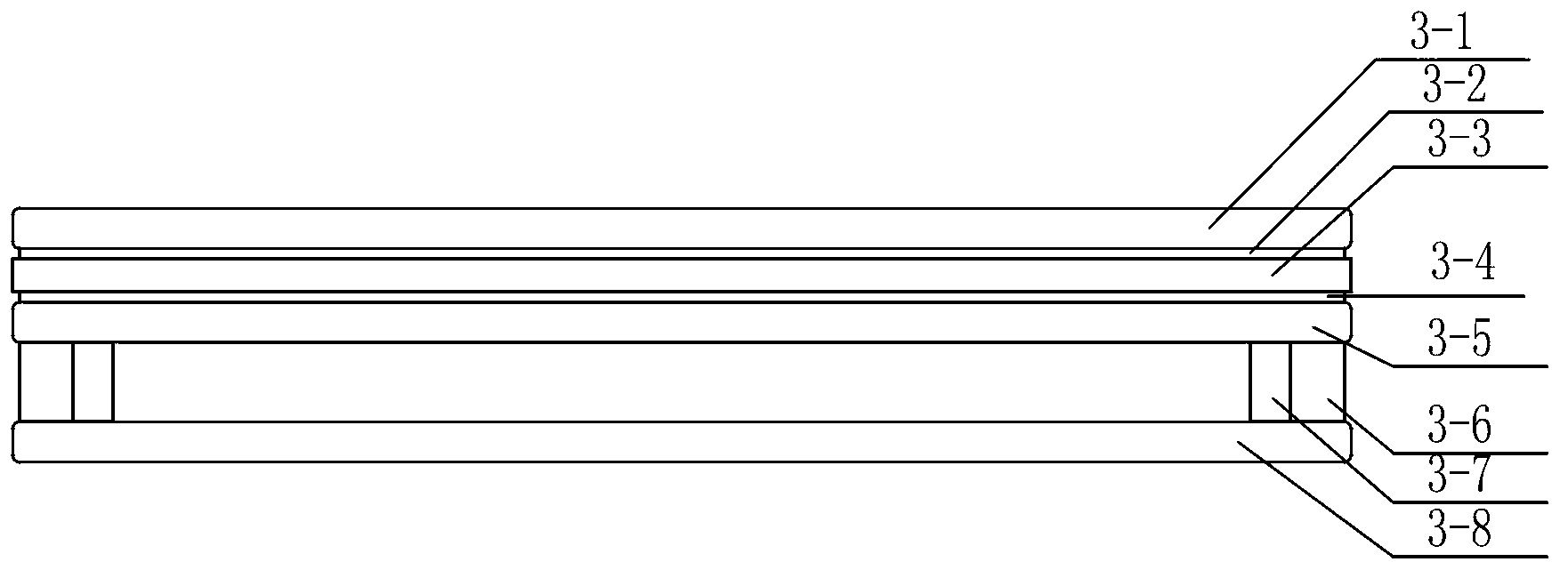

[0025] Such as image 3 As shown, the transparent insulating stone includes a stone 3-3, a first glass layer 3-1 and a second glass layer 3-5 are respectively arranged on the front and back of the stone 3-3, and the front of the stone 3-3 and the first glass layer One surface of the layer 3-1 is connected by the first PVB adhesive film 3-2, and the reverse side of the stone material 3-3 and a surface of the second glass layer 3-5 are connected by the second PVB adhesive film 3-4; The other surface of the second glass layer 3-5 is connected to the third glass layer 3-8 through the structural glue 3-6 at the edge, and an aluminum spacer is arranged between the second glass layer 3-5 and the third glass layer 3-8 3-7. Molecular sieves are filled inside the aluminum spacers 3-7; the first glass layer 3-1, the second glass layer 3-5 and the third glass layer 3-8 are made of tempered glass or semi-tempered glass.

[0026] The present invention adopts PVB film laminated glass to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com