Construction method for strengthening concrete floor

A construction method and concrete technology, applied in construction, building maintenance, building construction, etc., can solve problems such as large spacing between distributed reinforcement, unreasonable selection of reinforcement specifications, and minimum reinforcement ratio that cannot meet the demand, so as to ensure the coordinated bearing capacity , Improve the mechanical properties of the structure and reduce the effect of the main tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

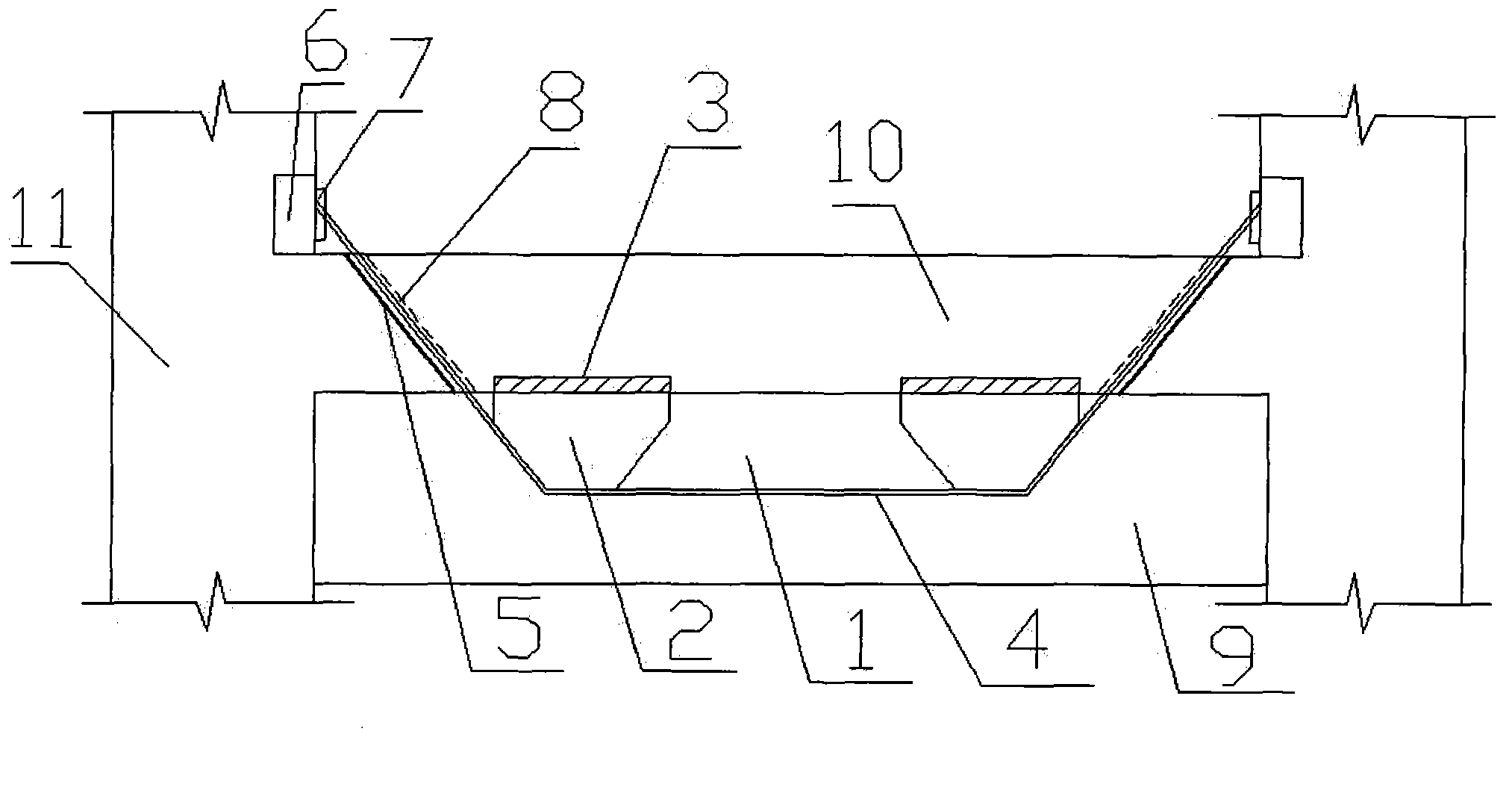

[0019] This embodiment includes shotcrete 1, steel steering block 2, embedded iron parts 3, prestressed steel strand 4, guide plate 5, pressure steel plate 6, anchor piece 7, high-strength cement slurry 8, mortar protective layer 9, concrete The steel steering block 2 is set at the lower quarter span of the floor slab 10. The thickness of the steel steering block 2 is 35 mm. The steel steering block 2 is welded to the embedded iron part 3 embedded in the concrete floor 10. The thickness of the embedded iron part 3 is 10 mm. The pre-embedded iron parts 3 are welded to the main reinforcement at the lower part of the concrete floor 11, and the shotcrete 1 is set between the two steel steering blocks 2 under the concrete floor 11. The plate 5 is used to fix the prestressed steel strand 4, the prestressed steel strand 4 passes through the slot hole and is fixed on the pressure-bearing steel plate 6 through the anchor 7, the pressure-bearing steel plate 6 is welded to the main reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com