Self-anchored suspension bridge construction method based on cable-stayed bridge beam forming conversion

A self-anchored suspension bridge and construction method technology, applied in cable-stayed bridges, suspension bridges, bridge forms, etc., can solve the problems of high cost of temporary piers, high risk of temporary pier collision with ships, and high rigidity requirements of temporary piers, and achieve no ship collision. The effect of risk, small change in stress, and no temporary stent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The invention discloses a construction method of a self-anchored suspension bridge based on the conversion of a cable-stayed bridge into a girder, comprising:

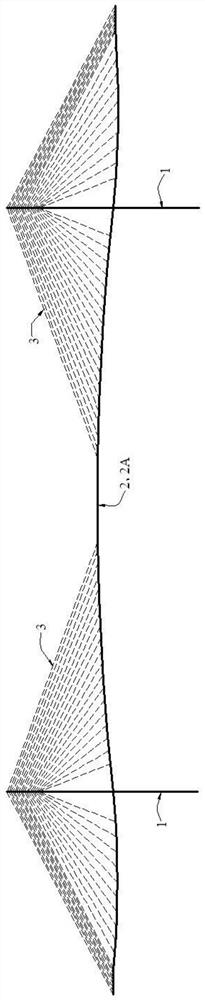

[0050] Step S1, see figure 2 , the construction forms a temporary cable-stayed bridge consisting of a cable tower 1, a main girder 2 and a plurality of temporary cable-stayed cables 3;

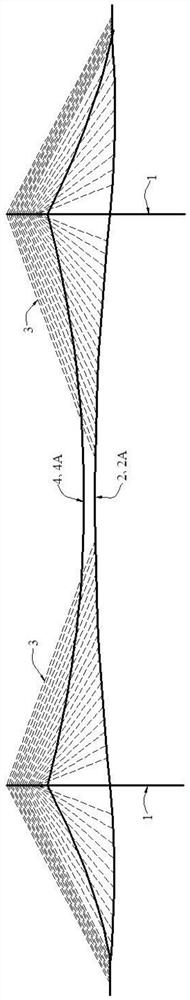

[0051] Step S2, see image 3 , according to the design drawings of the self-anchored suspension bridge, construct the main cable 4 at the corresponding positions on the cable tower 1 and the main girder 2, so that the main cable 4 is in the empty cable state 4A;

[0052] Step S3, see Figure 5 , install a corresponding number of suspenders 5 between the main cable 4 and the main girder 2 according to the installation positions of the suspenders recorded in the design drawings, and remove the temporary stay cables 3 to form the main girder 2 Self-anchored suspension bridges in bare beam state 2B;

[0053] Wherein, the install...

Embodiment approach

[0072] Such as Figure 4 As shown, in the step S3, the installation of the suspender 5 and the removal of the temporary stay cable 3 are carried out in the following manner:

[0073] Divide the main girder 2 into a plurality of sections S along the length direction, and perform operations on each section S, and when performing operations on any one of the sections S, first install the boom 5 located in the section S, and then dismantle it. Temporary stay cables 3 located in the section S;

[0074]In addition, each section S can be operated in any order, but it needs to meet the safe operation conditions: before performing any operation on any of the sections S, first calculate the number of times the main beam 2 installs the suspender 5 in the section S. The maximum negative bending moment of the main beam received is recorded as the maximum negative bending moment of the second main beam. If the maximum negative bending moment of the second main beam exceeds the safety thres...

Embodiment 3

[0078] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

[0079] Such as figure 1 with figure 2 As shown, in the step S1, after the construction of the cable tower 1 is completed, the main girder 2 and temporary cable-stayed cables 3 are constructed by the cantilever assembly method to form the temporary cable-stayed bridge. Wherein, the beam end anchorage position of the temporary stay cable 3 on the main beam 2 needs to avoid the permanent suspender anchorage point of the suspender 5 on the main beam 2 . The temporary stay cables 3 can be anchored to the cable tower 1 through conventional cable tower anchoring measures such as prestressed tooth plates, steel anchor beams, and pre-embedded wire splitting pipes.

[0080] The above is the basic implementation of the third embodiment, further optimization, improvement and limitation can be done on the basis of the basic implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com