Two-way thermal expansion valve

A thermal expansion valve and spool technology, applied in the direction of valve lift, valve device, valve details, etc., can solve the problems of low reliability, same supply, increased cost, etc., achieve small difference in system superheat, reduce system Superheat difference, effect of steady centered movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following description of the preferred embodiments is exemplary only, and not limiting of the invention and its application or usage.

[0040] The directions of "up", "down", "top" and "bottom" mentioned in the following description are only relative to the orientation of the thermal expansion valve shown in the drawings, and can vary with the orientation of the thermal expansion valve. change in actual direction.

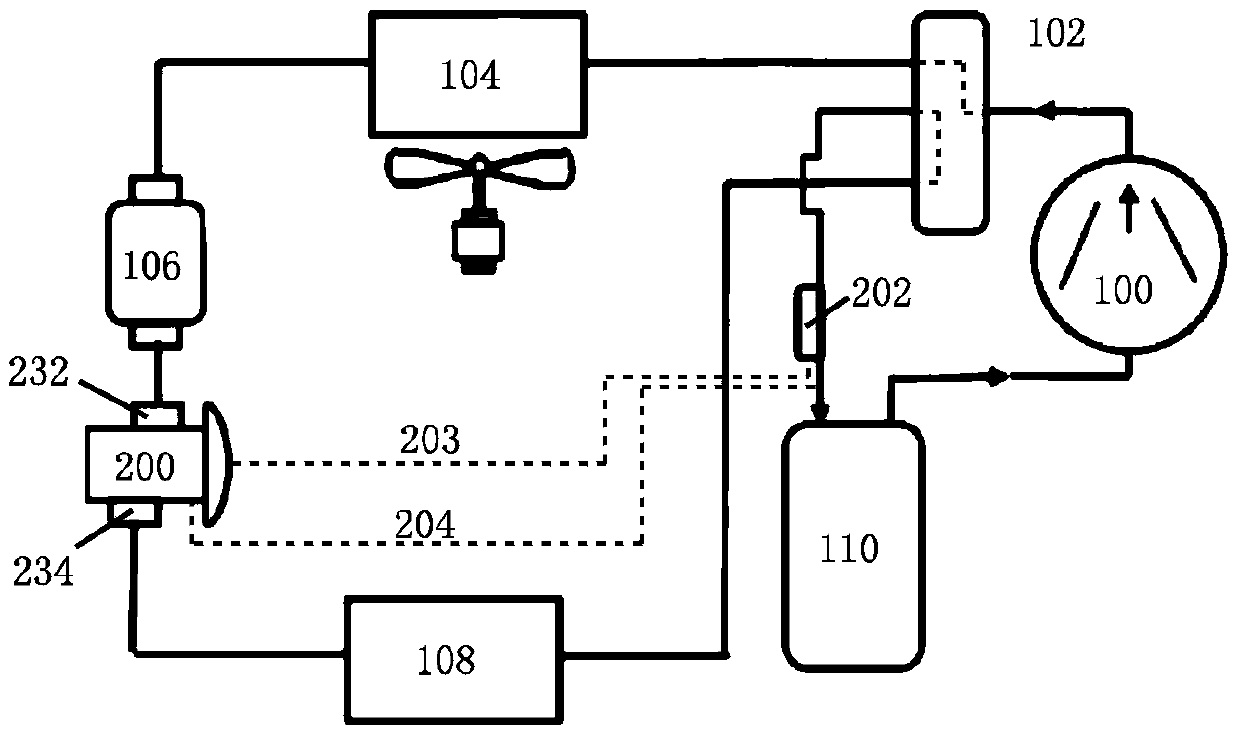

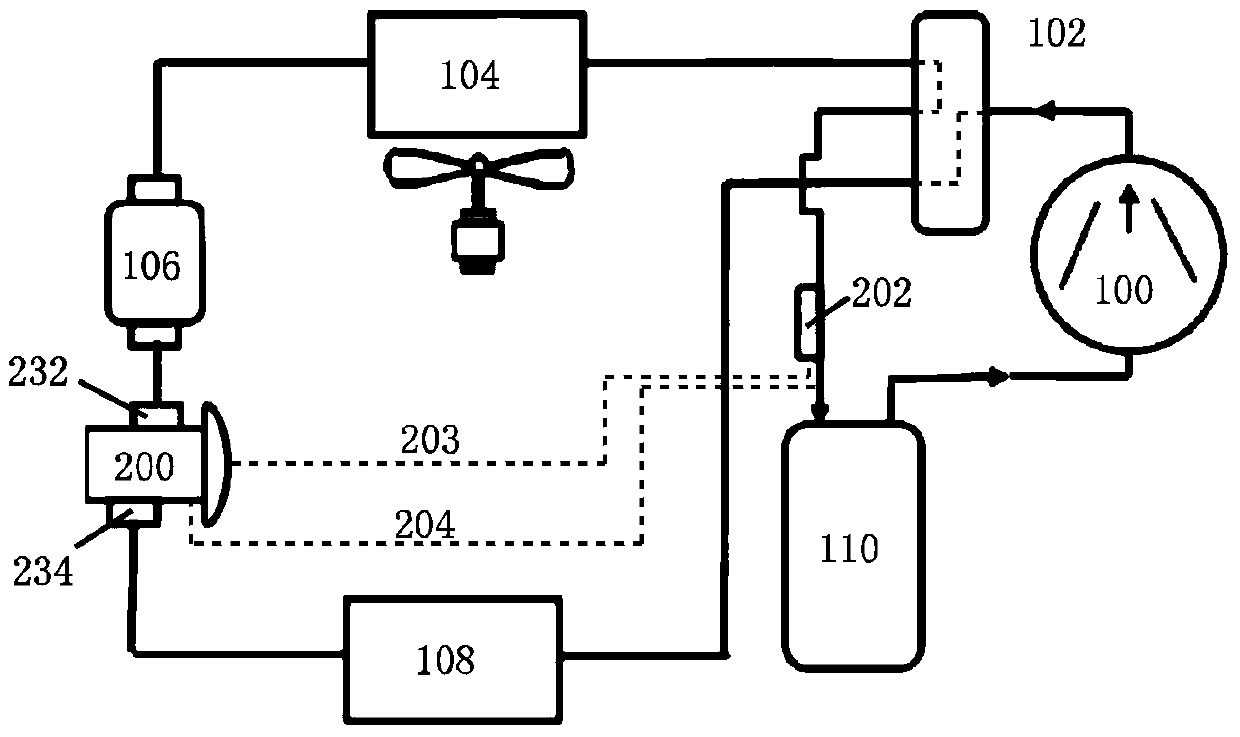

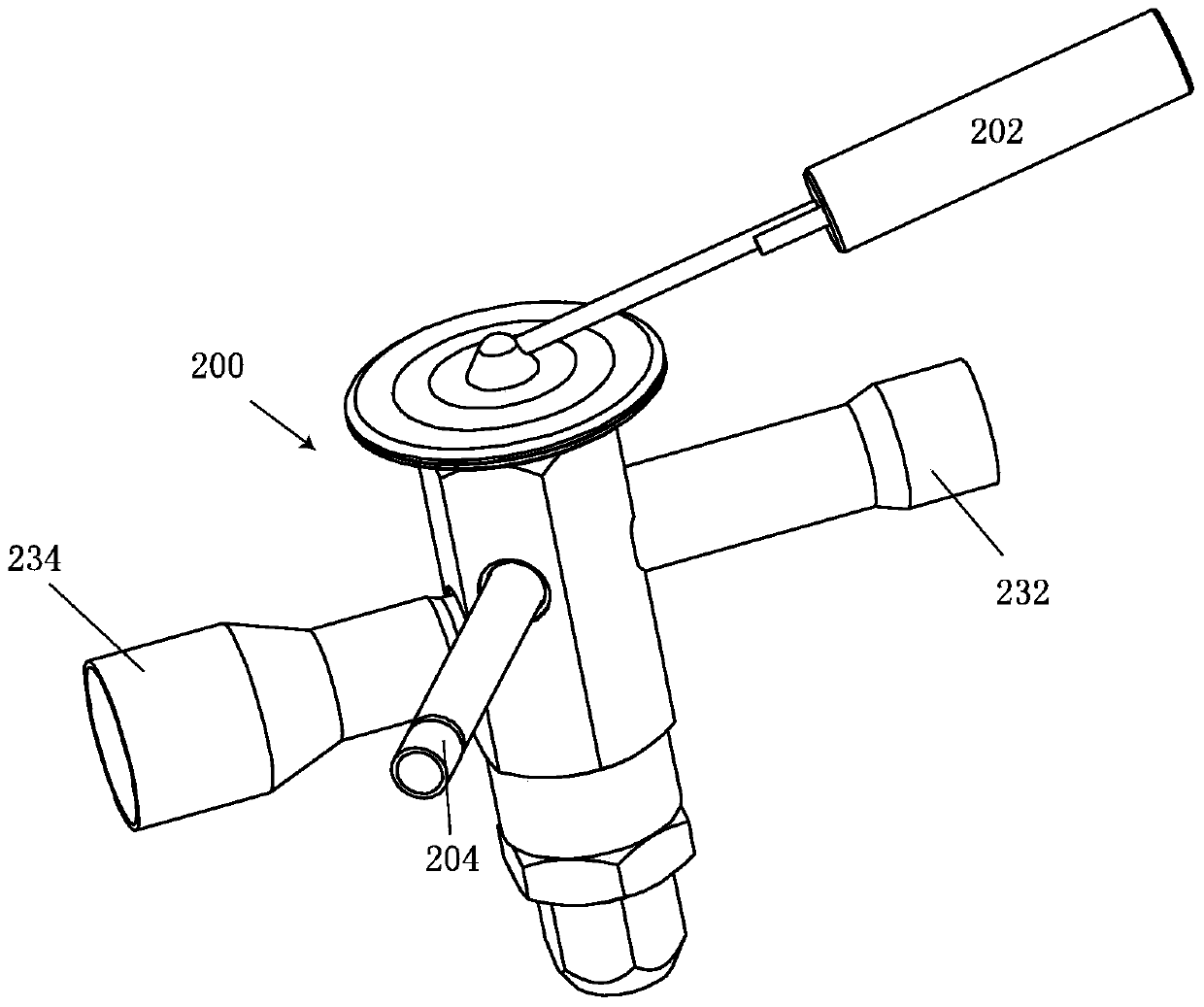

[0041] The following will refer to figure 1 and figure 2 A refrigeration system employing a bidirectional thermal expansion valve according to the present invention and its working principle are described.

[0042] In refrigeration conditions, such as figure 1 As shown, the compressor 100 discharges high-temperature and high-pressure liquid refrigerant (working medium), and the refrigerant enters the first heat exchange coil 104 (as a condenser) after passing through the four-way reversing valve 102 to become a low-temperature and high-pressure refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com